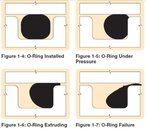

I agree with all of this except them being static in service. The pressure deforms the o-ring every time the valve is turned on. It moves, and then relaxes when pressure is released.

I agree, just easier for most to picture them as static once installed so I don't worry too much about that detail. I spent a lot of hours reading up on orings and their sealing surfaces a while back......partly because I am geeky and partly because I was machining oring ports at the time.