I read right over this when you posted it and it didn't "click". Just noticed it. Please elaborate...

The pre-test procedure is very important when testing any galvanized cylinder. Both, PST and Worthington have published bulletins specifying the pre-test procedure. The difference in test results is very significant if the procedure is not performed right before the actual test. I would make certain the hydro test facility follows the proper procedure before letting them test any of my cylinder.

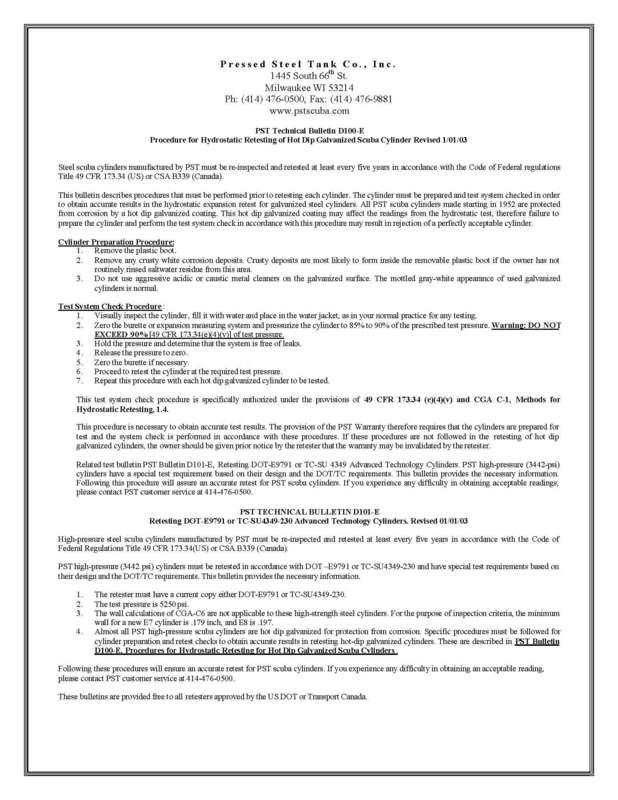

You can download a better copy from VintageDoubleHose.com, but this is what the bulletin looks like:

---------- Post added August 28th, 2015 at 11:53 PM ----------

Now understood. Thanks.

On another 72 topic:

I'm making progress on alkaline electrogalvanizing. Room temp. The two best references I've found are given below.

Zinc coatings in general: http://www.galvanizeit.org/images/uploads/publicationPDFs/Zinc_Coatings.pdf

Alkaline zinc electrogalvanizing: http://chemistry.unt.edu/~tgolden/group/2643_0_art_0_lc718m.pdf

-added this info as this is becoming a definitive thread on 72's and I'm still waiting for something better than crappy zinc paint...

I have had excellent results with ZRC and other similar galvanizing paint. The zinc does form a chemical bond with the steel that is stronger than the iron-oxide. Therefore, the paint can still be scratch, but rust will not migrate under the paint.

Rust migrating under the paint is the week-link for all other paints applied to steel cylinders.

Zink rich galvanizing paint is essentially what Faber is doing now-a-days. They do have what seems to be a very good process, but it seems to rely on the iron-zinc chemical bond.

Over the decades (starting in the 1970s at my first LDS job) I have seen several attempts at aftermarket galvanizing scuba cylinders. The outside finish on some of them looked excellent. But, on every single one of those attempts, some of the acids used in the process (cleaning or otherwise) leaked inside the cylinder and ruined it.

It is very possible that someone has been successful with aftermarket galvanizing process, but the ones that I have seen had to be condemned due to excessive rust an pitting on the inside after the process.

I have also seen a few cylinders (in different dive shops) that were chrome plated for display. I never asked how did the inside looked, but they were only used for display so it probably didnt matter.

Just be aware that you may risk ruining the cylinder.

Note: galvanized steel 72 with 3/4" valve neck are not that hard to find. I dive mostly in salt water so I do not own any steel 72 that is not galvanized (and have 3/4" neck).