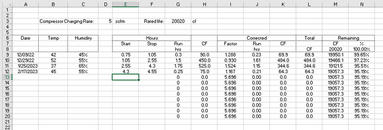

I will admit I'm not the smartest guy out there, but if the filter tower is left pressurized I can't see how there's a life span of 6 months? There would be nothing inside the tower to filter if left untouched?I've been considering that too. I noticed that Nuvair states a maximum operation life of 6 months - I'm assuming due to the Hopcalite. With my likely use (it is just me), time not volume would be the more likely limiting factor and cost/unit will outweigh cost/cuft.

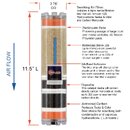

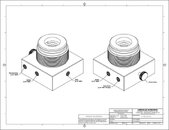

Now, portability is also a big factor. I'd like to be able to mount the filtration and keep it within the frame boundary - at least vertically. If the big boat dream ever comes through and I'm diving every day, I can always substitute or add a big bulkhead-mounted 24-35" tower.

I could be wrong.