Packhorse

Contributor

I think you will need to have the driver after the switch. So it will have to be in the light head. But that is simple enough just bore out the heat sink and mount them inside. 5 will only be about 20mm high. I did say 5 before not 7. 5 will give you 7 amps. I dont think there is much benefit running more than 7 amps. Maybe even go with 4 at 5.6 amp. Still plenty of lumen and less heat and more run time.

You could have 2 rows of 3 cells then 2 cells on their side for a 8 cell pack that is shorter than a 9 cell pack.

No you dont. there is a tricky way to wire AMC 7135 drivers for twin LED setups.

You will have to up the voltage though which is a good thing.

Run a 2P7S pack giving 8.4 volt. or just a 7S pack

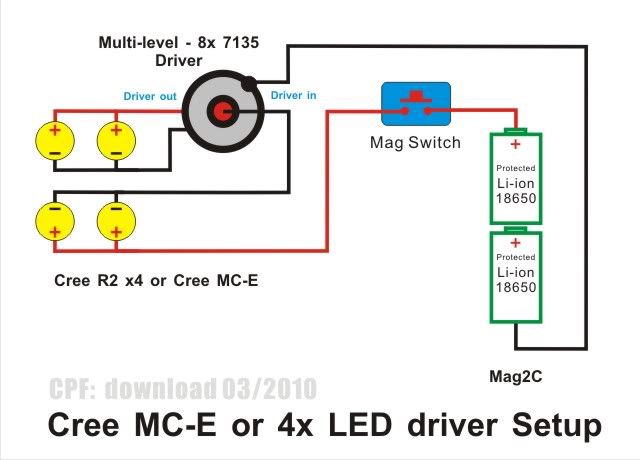

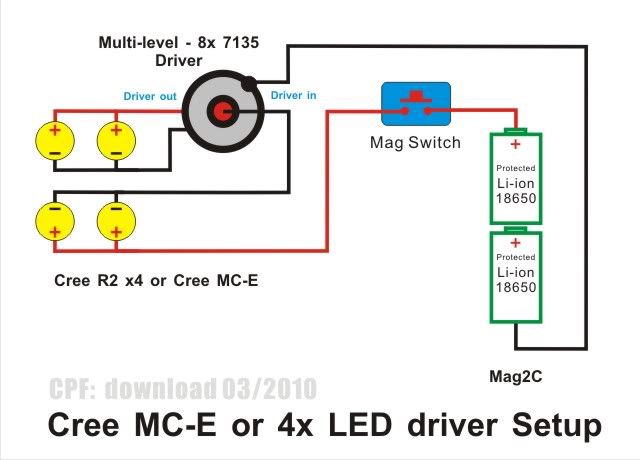

Check out this pic. Ignore the paralleled LEDs. The AMC7135 should have a total of 4 or 5 four chip boards. You could have 1 board wired to one stage of the switch for low then switch in the next 3/4 for high.

You could have 2 rows of 3 cells then 2 cells on their side for a 8 cell pack that is shorter than a 9 cell pack.

However, to run your double LED, you'll need twice as many boards (12 or 14 total)

No you dont. there is a tricky way to wire AMC 7135 drivers for twin LED setups.

You will have to up the voltage though which is a good thing.

Run a 2P7S pack giving 8.4 volt. or just a 7S pack

Check out this pic. Ignore the paralleled LEDs. The AMC7135 should have a total of 4 or 5 four chip boards. You could have 1 board wired to one stage of the switch for low then switch in the next 3/4 for high.