I bought this printer over a year ago and it's had spotty success. I had a problem with my Tevo Tornado that I finally traced down to OctoPrint, Marlin, and the board interface. I installed the Sonic Pad, ran it's program on my printer and all I got was dots on my little screen. DOTS!!! I did this, adjusted that, scratched my head and finally saw a video where they told me that this was normal. Jeez Louise. I was really stressing on that. I discarded that little display, reloaded the printer and voila! That's French for lookee here! I really, really like Klipper over Marlin, and out of the box, it's noticeably faster with a better finish. Not perfect, so today I thought I would give their g-sensor a try. I printed two g-sensor mounts. One is for the hot end and the other is for the bed. I took care to set the printing of the bed mount towards the front, so as to avoid any printhead collisions. I also used 3/4 of a can of White Rain to glue that puppy down. I took pains to carefully drill and tap the hot end sensor to accept M3 screws. Yeah. That didn't really work. On the first try, I found the sensor hanging loose.

We're gonna neeed a bigger bolt!

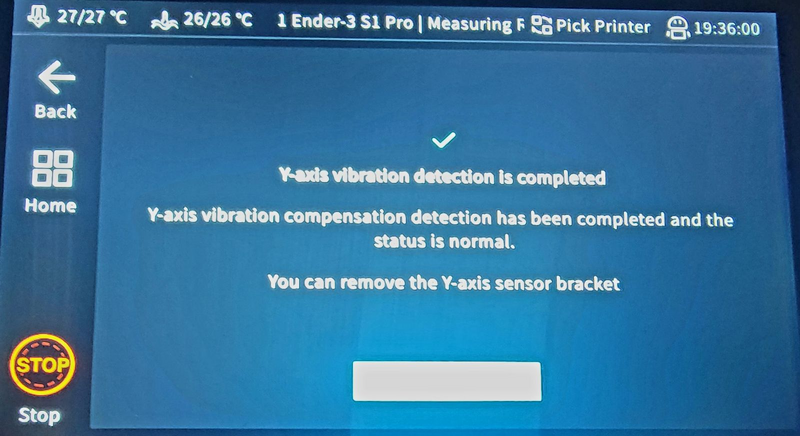

No use in going further, so I rebooted the Sonic Pad and used longer cap headed bolts and nuts on the bottom. Stage one was successful, so I set up for the second and final stage of this calibration.

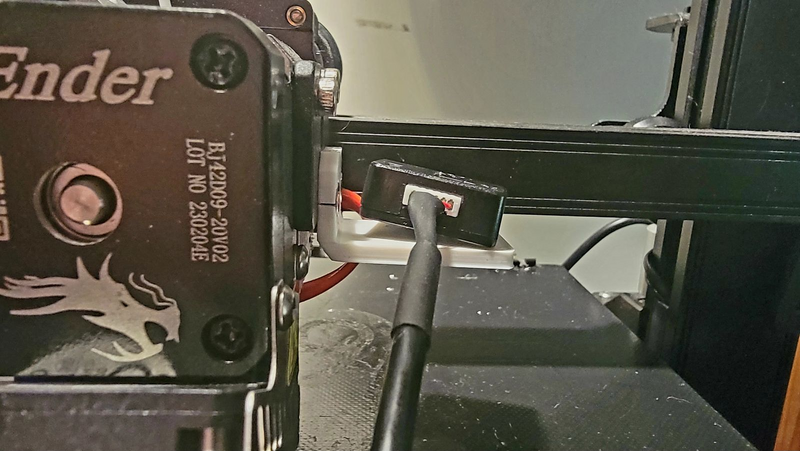

Screwed, glued, and taped for solid performance!

I guess we'll see how much better she performs in the coming days!

We're gonna neeed a bigger bolt!

No use in going further, so I rebooted the Sonic Pad and used longer cap headed bolts and nuts on the bottom. Stage one was successful, so I set up for the second and final stage of this calibration.

Screwed, glued, and taped for solid performance!

I guess we'll see how much better she performs in the coming days!