I'm looking for assistance selecting the components to replace the WA MR11 HID Ballast & lamp in my cannister light. I'm mechanically adapt, but an electronics duff-ass

My power source is a 3.3AH 12V LI battery.

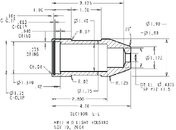

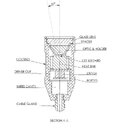

I know a need a buck regulator , suitable LED, heat sink & reflector or optic to fit in my lamp housing.

(Lamp housing section included).

Would like about 800 lumens & 2 hours run time. Simple 1 mode on/off

LED: XML-T6 ?

Looking at this refector: 35mm*35mm Aluminum Textured/OP Reflector for Cree LED Emitters (2-Pack)

I have lots of room in the battery canister.

any help will be appreciated

Mike D

My power source is a 3.3AH 12V LI battery.

I know a need a buck regulator , suitable LED, heat sink & reflector or optic to fit in my lamp housing.

(Lamp housing section included).

Would like about 800 lumens & 2 hours run time. Simple 1 mode on/off

LED: XML-T6 ?

Looking at this refector: 35mm*35mm Aluminum Textured/OP Reflector for Cree LED Emitters (2-Pack)

I have lots of room in the battery canister.

any help will be appreciated

Mike D