Russoft

Contributor

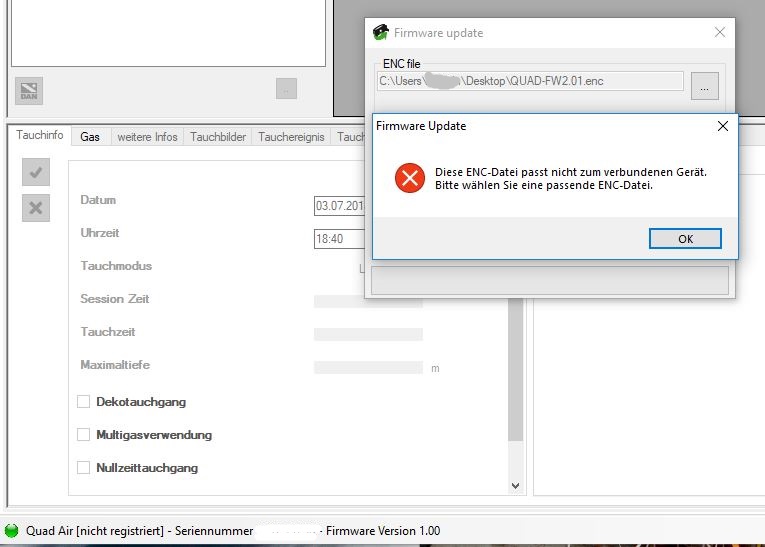

A follow up from earlier in the week.

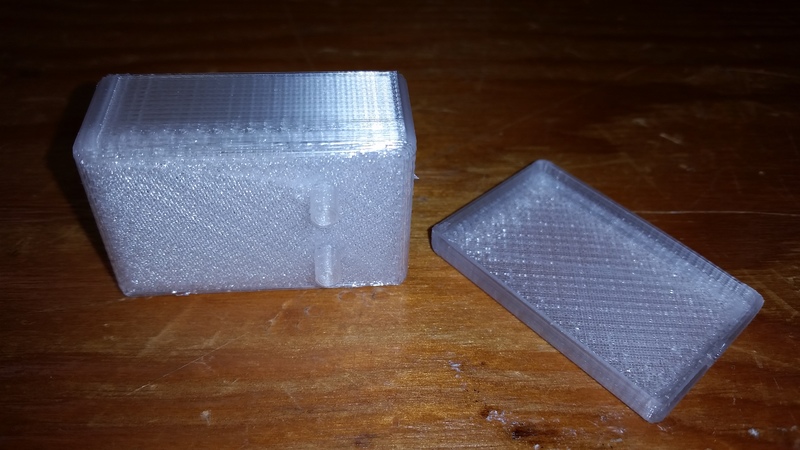

I decided I wanted something more user friendly and travel friendly. I 3D printed a little enclosure for the circuitry. I'll share this file with anyone who is interested.

For the Puck, the contacts are 12.1 mm apart (a little less than 1/2"). The Puck Pro has a slightly larger distance but the same distance works for both, and this interface does work for both the Puck and Puck Pro (as mentioned earlier). I have independently verified this.

If you can find center contacts for a BNC female jack (common coaxial RF connector for ham radio), they fit onto the Puck contacts perfectly. Not so for the Puck Pro.

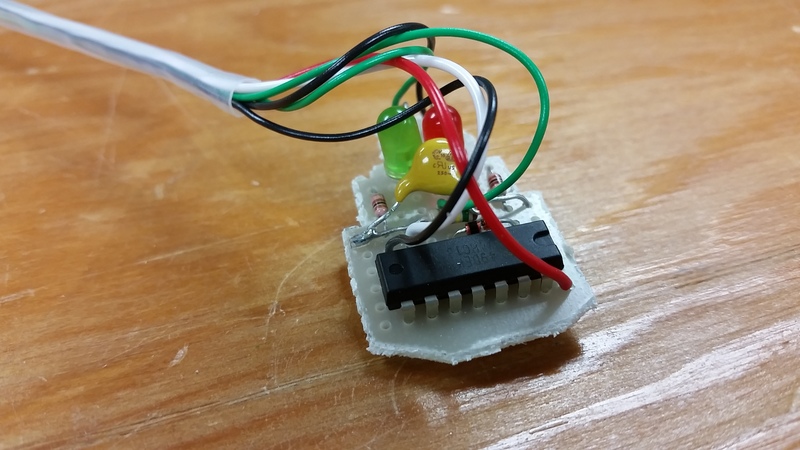

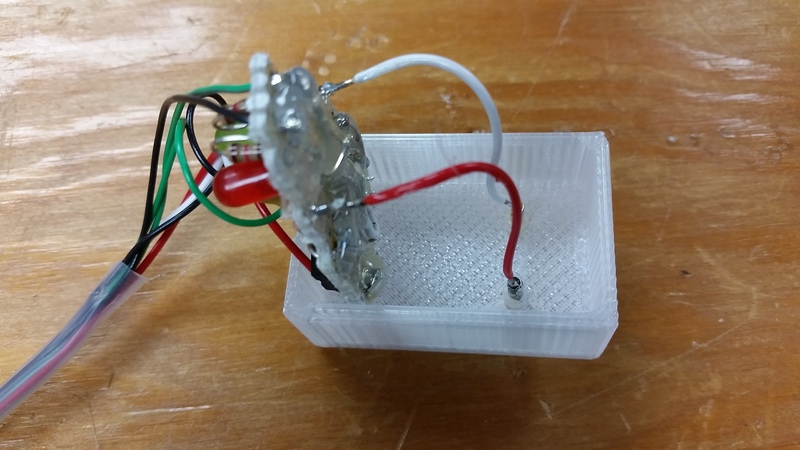

Circuitry was soldered on a perf board, though if you have patience to etch your own PCB, all the more power to you. This works just fine if you aren't planning mass production.

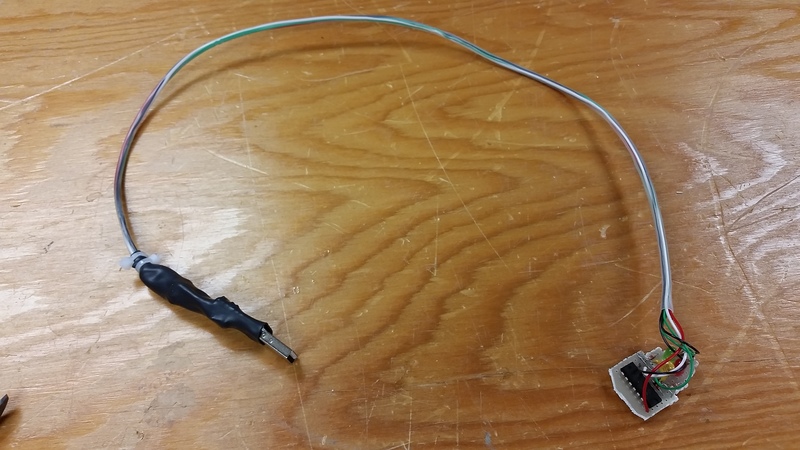

I used 6 wires to connect the CP2102 (left, in heat shrink) to the circuit (right). I used shrink tubing to hold the bundle together. The 6 pins on the CP2102 are the 3.3V, GND, SUS, !SUS, TXD, and RXD. Refer to circuitry provided by others here.

Data and GND pins connect to the brass pins which stick through on the bottom side of the box, shown below.

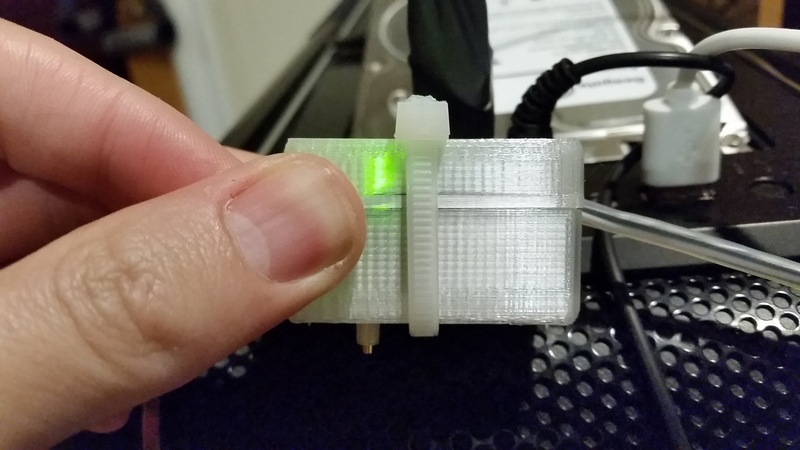

Assembled and plugged into the computer. I used a clear plastic (PETG filament) for the 3D printed enclosure so you can see the red and green LEDs.

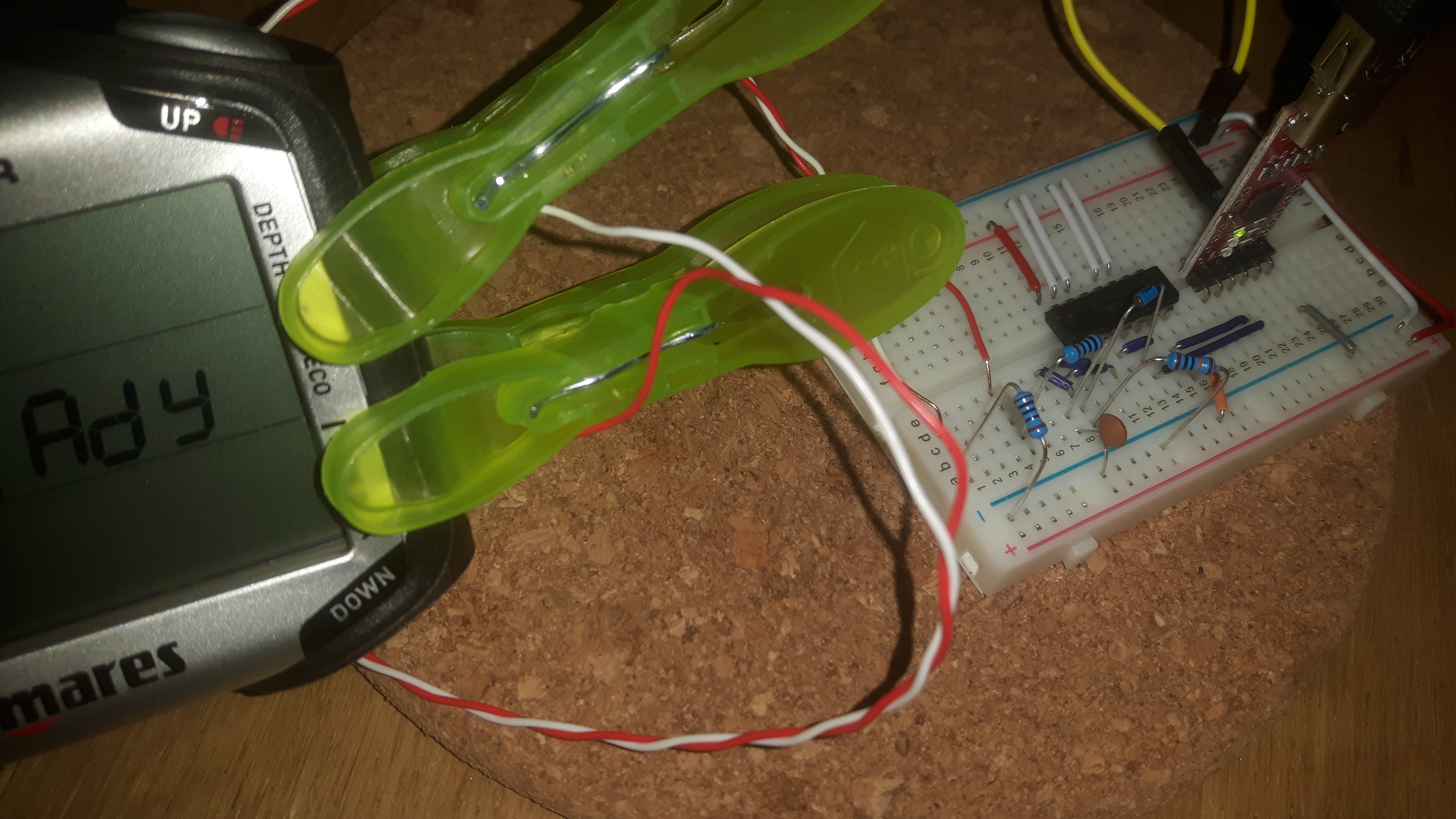

Plugged into the Puck. I measured the voltage with a voltmeter to determine polarity and found the GND pin to be the one nearest the strap.

I decided I wanted something more user friendly and travel friendly. I 3D printed a little enclosure for the circuitry. I'll share this file with anyone who is interested.

For the Puck, the contacts are 12.1 mm apart (a little less than 1/2"). The Puck Pro has a slightly larger distance but the same distance works for both, and this interface does work for both the Puck and Puck Pro (as mentioned earlier). I have independently verified this.

If you can find center contacts for a BNC female jack (common coaxial RF connector for ham radio), they fit onto the Puck contacts perfectly. Not so for the Puck Pro.

Circuitry was soldered on a perf board, though if you have patience to etch your own PCB, all the more power to you. This works just fine if you aren't planning mass production.

I used 6 wires to connect the CP2102 (left, in heat shrink) to the circuit (right). I used shrink tubing to hold the bundle together. The 6 pins on the CP2102 are the 3.3V, GND, SUS, !SUS, TXD, and RXD. Refer to circuitry provided by others here.

Data and GND pins connect to the brass pins which stick through on the bottom side of the box, shown below.

Assembled and plugged into the computer. I used a clear plastic (PETG filament) for the 3D printed enclosure so you can see the red and green LEDs.

Plugged into the Puck. I measured the voltage with a voltmeter to determine polarity and found the GND pin to be the one nearest the strap.