These are the test specs from the class I taught through 2022 when I retired.

UPDATED Test Bench Specifications 9/29/2019

Test Range

Intermediate pressure 135 psi, +/- 5psi

Intermediate pressure creep: No more than 5 psi in 15 seconds

Cracking pressure 1.0 – 1.2 with adjustment knob fully open

Closing the adjustment knob will add approximately 1.0

Vacuum leak test 1. No leaks allowed

Bubble leak test 1. No leaks allowed

Torque Specifications

Part Description Torque

D1, D2, D3 DIN Inlet 225-230 inch pounds

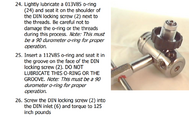

DIN Locking Screw 150 inch pounds

HP Port Plug, LP Port Plug 35-40 inch pounds

Turret Bolt 120 - inch pounds

5th Port replacing turret bolt 170 - inch pounds

D2 and D3

The HP chamber is the same as the D2 80-90-inch lbs.

Note that with the D3, make sure the hex is seated firmly to avoid stripping the fitting!

Din housing parts are the same as the D1 – 225-230 for the Inlet and 150 for the locking screw

D3 Turret to body connection, no torque just tight with no movement, binding against thrust washer or visible gap.

Yoke nut 225 - inch lbs.

NANO and EXP Yoke Nut 150 inch lbs.