One of the frustrations about Scuba Tools hook spanners is the lack of a broach for a torque wrench. Yeah, you can hook your luggage scale in the hole in the end and do the math, but a torque wrench is faster.

Bruce's new Oceanic #5 has one, but he points out that it decreases the strength of the handle when torquing.

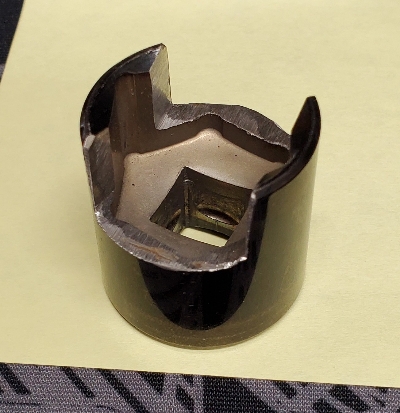

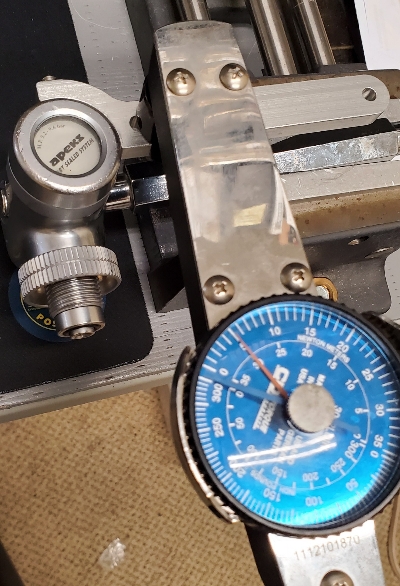

So I made a cheater out of an unused socket.

I carefully cut a groove of exactly the width of the handle with a cutting wheel (see below).

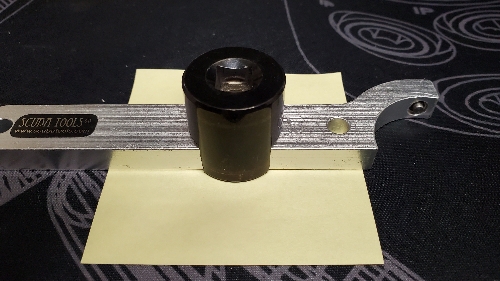

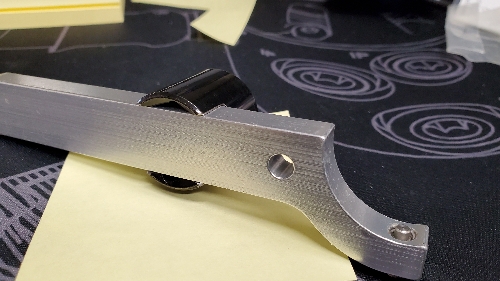

Now the cheater just slips over the handle at any point you like. If you're using a torque wrench in the standard position, this allows you to slide it in or out to an exact length to recompute torque based on the longer lever arm.

Or, since it's a cheater , you can cheat once again and use it at right angles.

, you can cheat once again and use it at right angles.

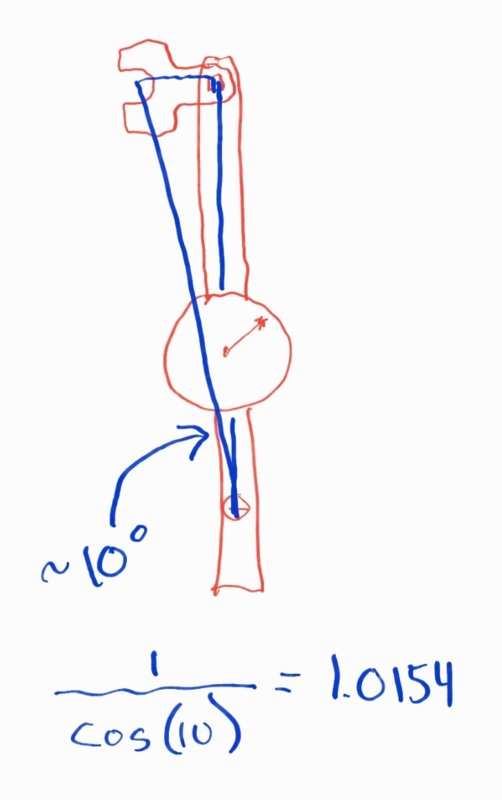

With a small enough angle, the extra lever arm length is within the margin of error of the tool, and you can just set it for what you want.

I showed it to Bruce, and he seemed to like it. But just in case he doesn't start making it to sell any time soon, that's how I did it.

But don't be a knucklehead like I was and forget to cut the slot in line with the broach for the torque wrench. Makes it kinda hard to do the maths thing...

Doh!

Bruce's new Oceanic #5 has one, but he points out that it decreases the strength of the handle when torquing.

So I made a cheater out of an unused socket.

I carefully cut a groove of exactly the width of the handle with a cutting wheel (see below).

Now the cheater just slips over the handle at any point you like. If you're using a torque wrench in the standard position, this allows you to slide it in or out to an exact length to recompute torque based on the longer lever arm.

Or, since it's a cheater

With a small enough angle, the extra lever arm length is within the margin of error of the tool, and you can just set it for what you want.

I showed it to Bruce, and he seemed to like it. But just in case he doesn't start making it to sell any time soon, that's how I did it.

But don't be a knucklehead like I was and forget to cut the slot in line with the broach for the torque wrench. Makes it kinda hard to do the maths thing...

Doh!