kawaboy

Registered

Hello all

I'm in the middle of my latest project (HID canister light) and I have run into a couple of obstacles regarding the test tube and the ballast.

The acrylic caps turned out really well and I am in the process of turning the slug out of aluminum and I need some dimensions before I continue. I have a copy of the Divelight Companion and are using their dimensions.

Materials:

90mm OD PVC water pipe for canister 5mm wall thickness

20mm clear acrylic for caps

Reflector from an old Eveready Dolphin torch

Light kit as below

d cell NiMH x 10

Aluminium for slug

Misc items like switches, boots, cable, and various bits from my odds and ends box

I'm still looking for something that will house the reflector.

I don't want to reinvent the wheel so any proprietary bits will have to be purchased

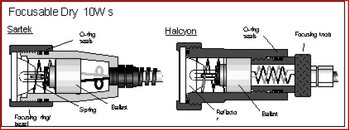

The Dive right tubes are approx 30mm x 50mm and these are a bit on the short side to accommodate the globe. I am still waiting for a reply from the Halcyon dealer here in Oz for their TT dimensions.

The globe I am using has an H3 base (22mm diam) and the globe is 37mm long, measured from the front of the base to the tip of the globe. As close as I can figure, I will need a TT at least 65mm long on the inside.

The light I am using is an automotive 50w conversion kit available on ebay.

SUPER BRIGHT 50W XENON HID KIT H1 H3 H7 4300K 6000K 55W - eBay (item 300348030883 end time Sep-24-09 00:21:43 PDT)

(No vested interest)

Would anyone on the board be able to point me in the right direction as far as sourcing these test tubes?

Re: Ballast.

Has anyone played around with this style of ballast lights before? I want to mount the ballast in the canister and the head will be about 1.8m away. I contacted the seller and they have "tested" the ballast at a distance of 1.6m away from the globe so I think it should be okay at 1.8m. Comments appreciated.

I am aware that the automotive lights have a much higher ignition voltage so all care will be taken with that regard.

I'll be doing a long burn test to find out how much heat is generated by the ballast housing and make the necessary arrangements for heat dissipation. Any suggestions regarding this are more than welcome.

Oh BTW, I tried to order some bits from McM Carr but "due to the complexity of United States Export regulations", no luck buying bits from Australia. Go figure...

Oh well...

I'll try to post some pix when I'm a bit more advanced with this project.

Regards

Joe

I'm in the middle of my latest project (HID canister light) and I have run into a couple of obstacles regarding the test tube and the ballast.

The acrylic caps turned out really well and I am in the process of turning the slug out of aluminum and I need some dimensions before I continue. I have a copy of the Divelight Companion and are using their dimensions.

Materials:

90mm OD PVC water pipe for canister 5mm wall thickness

20mm clear acrylic for caps

Reflector from an old Eveready Dolphin torch

Light kit as below

d cell NiMH x 10

Aluminium for slug

Misc items like switches, boots, cable, and various bits from my odds and ends box

I'm still looking for something that will house the reflector.

I don't want to reinvent the wheel so any proprietary bits will have to be purchased

The Dive right tubes are approx 30mm x 50mm and these are a bit on the short side to accommodate the globe. I am still waiting for a reply from the Halcyon dealer here in Oz for their TT dimensions.

The globe I am using has an H3 base (22mm diam) and the globe is 37mm long, measured from the front of the base to the tip of the globe. As close as I can figure, I will need a TT at least 65mm long on the inside.

The light I am using is an automotive 50w conversion kit available on ebay.

SUPER BRIGHT 50W XENON HID KIT H1 H3 H7 4300K 6000K 55W - eBay (item 300348030883 end time Sep-24-09 00:21:43 PDT)

(No vested interest)

Would anyone on the board be able to point me in the right direction as far as sourcing these test tubes?

Re: Ballast.

Has anyone played around with this style of ballast lights before? I want to mount the ballast in the canister and the head will be about 1.8m away. I contacted the seller and they have "tested" the ballast at a distance of 1.6m away from the globe so I think it should be okay at 1.8m. Comments appreciated.

I am aware that the automotive lights have a much higher ignition voltage so all care will be taken with that regard.

I'll be doing a long burn test to find out how much heat is generated by the ballast housing and make the necessary arrangements for heat dissipation. Any suggestions regarding this are more than welcome.

Oh BTW, I tried to order some bits from McM Carr but "due to the complexity of United States Export regulations", no luck buying bits from Australia. Go figure...

Oh well...

I'll try to post some pix when I'm a bit more advanced with this project.

Regards

Joe