Guba

Contributor

Bryan (and anyone else who's interested),

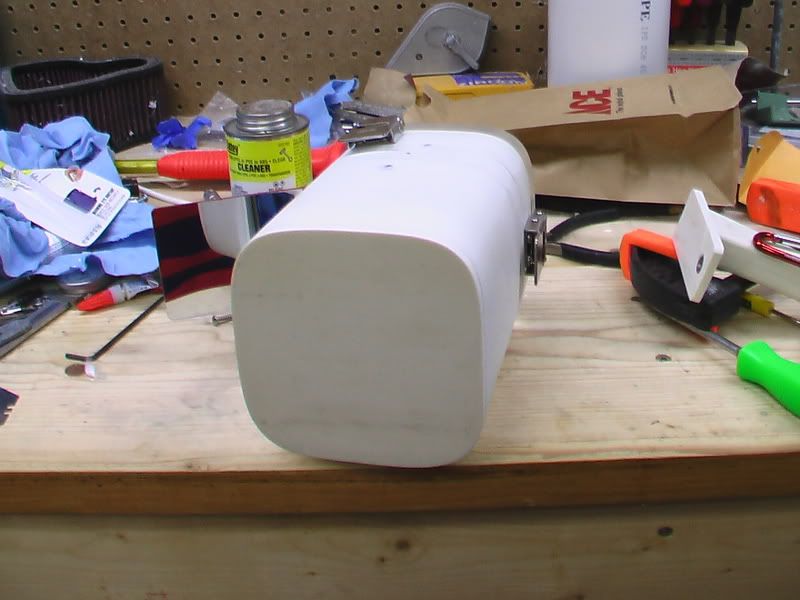

I've posted a few pics, so you might want to take a look. Some parts are still a bit rough (first attempt, mind you), but you can get the idea. My next camera will be much smaller, so the next housing will be as small as I can get it. Still, this one works well, and as I said before--they're loads of fun, both to make and to use!

I've posted a few pics, so you might want to take a look. Some parts are still a bit rough (first attempt, mind you), but you can get the idea. My next camera will be much smaller, so the next housing will be as small as I can get it. Still, this one works well, and as I said before--they're loads of fun, both to make and to use!