First, halocline was absolutely right - I looked at the wrong invoice. Tribolube 66 IS cheaper - $176/lb vs $210/lb for the Tribolube 77. Now I'll feel a little better about trying it.  Will probably try both silicone and Trib on two Mk10s.

Will probably try both silicone and Trib on two Mk10s.

Second, to answer couv, your description of the geometry of the SPEC boot was an ahah! moment for me. I'm now seeing the concept as a second chamber that transmits pressure via the ambient holes to the inside chamber. That flexing of the softer roof with essentially no holes means that all the water movement toward the chamber(s) takes place in the SPEC boot, OUTSIDE the regulstor. Ingenious! Gosh, I wish I had one.

I will have to rethink this whole thing. My idea just basically kept the mess down, while still allowing water into the environmental chamber. This is a whole 'nother concept. I'm really sorry it didn't catch on. Engineering-wise it is terrific.

Hope the group out there can help me think of a way to duplicate this. I'm still a fan of high flow simple pistons, and for the price of a little mess, this was a great concept. I didn't know enough back in the 80's to try and find one when I bought my first Mk10. Darn!

Actually, a softer version that's removable after a few dives may be even better: the water is outside, so you remove the boot, wipe it down, syringe a new second thin layer of goop into the groove, stretch the boot into place and wipe off the excess. Now a three-year annual begins to make sense.

But what am I missing? Why is the boot concave outside (depressurized)? The knife edge has come off the seat, so environmental chamber is SMALLER, right? And any bubbles in the goop are now back to normal size. All that should make the boot bulge.

---------- Post added March 6th, 2013 at 08:48 AM ----------

Never mind. I was so excited to see this info this morning that I replied on my phone lying in bed before I engaged my brain. When the piston comes off the seat, the environmental chamber obviously gets bigger, and the SPEC boot sucks in. Duh.

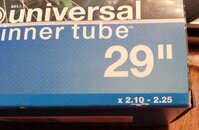

OK, now to figure out how to design a boot. I'm thinking two inner tubes, just slightly different diameters. One is cut in a ~1/2" strip to form the boot. The smaller one is cut into two tiny rings, and I'll try to glue one to each edge of the wide outer ring. That will form the shoulders for the space inside the boot.

But I don't think I can do it and have it stand up to much use.

What stretchy thing is shaped like the boot that we could use?

Second, to answer couv, your description of the geometry of the SPEC boot was an ahah! moment for me. I'm now seeing the concept as a second chamber that transmits pressure via the ambient holes to the inside chamber. That flexing of the softer roof with essentially no holes means that all the water movement toward the chamber(s) takes place in the SPEC boot, OUTSIDE the regulstor. Ingenious! Gosh, I wish I had one.

I will have to rethink this whole thing. My idea just basically kept the mess down, while still allowing water into the environmental chamber. This is a whole 'nother concept. I'm really sorry it didn't catch on. Engineering-wise it is terrific.

Hope the group out there can help me think of a way to duplicate this. I'm still a fan of high flow simple pistons, and for the price of a little mess, this was a great concept. I didn't know enough back in the 80's to try and find one when I bought my first Mk10. Darn!

Actually, a softer version that's removable after a few dives may be even better: the water is outside, so you remove the boot, wipe it down, syringe a new second thin layer of goop into the groove, stretch the boot into place and wipe off the excess. Now a three-year annual begins to make sense.

But what am I missing? Why is the boot concave outside (depressurized)? The knife edge has come off the seat, so environmental chamber is SMALLER, right? And any bubbles in the goop are now back to normal size. All that should make the boot bulge.

---------- Post added March 6th, 2013 at 08:48 AM ----------

Never mind. I was so excited to see this info this morning that I replied on my phone lying in bed before I engaged my brain. When the piston comes off the seat, the environmental chamber obviously gets bigger, and the SPEC boot sucks in. Duh.

OK, now to figure out how to design a boot. I'm thinking two inner tubes, just slightly different diameters. One is cut in a ~1/2" strip to form the boot. The smaller one is cut into two tiny rings, and I'll try to glue one to each edge of the wide outer ring. That will form the shoulders for the space inside the boot.

But I don't think I can do it and have it stand up to much use.

What stretchy thing is shaped like the boot that we could use?