ok. point taken, Pete. Nevertheless I'll stand by my observation that escaped o-rings are fact of life with yoke fittings. With a DIN fitting if it's too "loose" when you attach it then it will leak and you'll hear it immediately when you put the kit together. With a yoke fitting that is attached too "loose" it can "appear" to be correct when you charge the reg and the o-ring can escape (vigorously) at some unpredictable moment after that.

R..

I have witness a DIN connection have an O-ring let go a while after it was pressurized, just as you are describing that you have witness on yoke connections.

As I already mentioned, both connections can malfunction if they are not properly attached or the parts have been previously damaged.

I can’t comment on you personal experience with yoke connections, but where by any chance while using rental tanks? All rental tanks that I am familiar with are notorious for the abuse they receive. The valves surfaces many times are full of dings and imperfections, the O-rings look like have not been replaced in years, and corrosion is very normal. It is often surprising that they work at all, but most of the time they do. That being said I have never had a blown O-ring on any connection I have ever made in the past 40+ years (yoke or DIN, rental tank or personal)… now I just probably jinx myself…

A DIN valve would just not be able to take the kind of abuse that a yoke valve can. If you drop a tank on a DIN valve it will bend. You may still be able to screw in you regulator, but it will scratch the chrome on you regulator threads.

Every time I have witness a blown O-ring, yoke or DIN, it can be easily traced to operator error (normally beginner) or equipment damaged (bent yoke, damaged O-ring surface, etc).

Statistically makes a lot of sense that there will be more O-ring blown on yoke connections… they are by far the most common rental connection, they are probably the most common connection used by beginners, and at least in the US and Caribbean they are also by far the most common connection.

Deutsches Institut für Normung was established in 1917 and the valve specs were created by them. I remember them being called "yoke" back in 1969 and I remember a reference to "300 bar" regulators. I wonder if the Europeans first started calling them DIN valves and just when they were first developed.

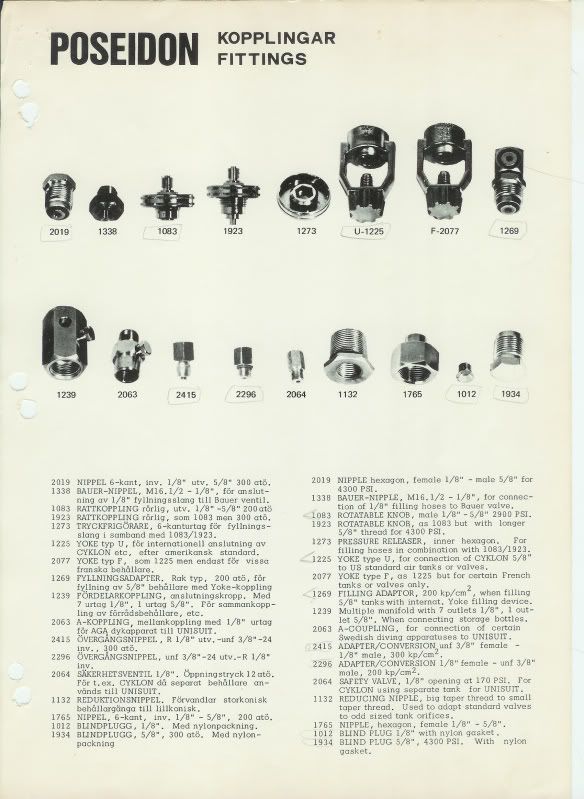

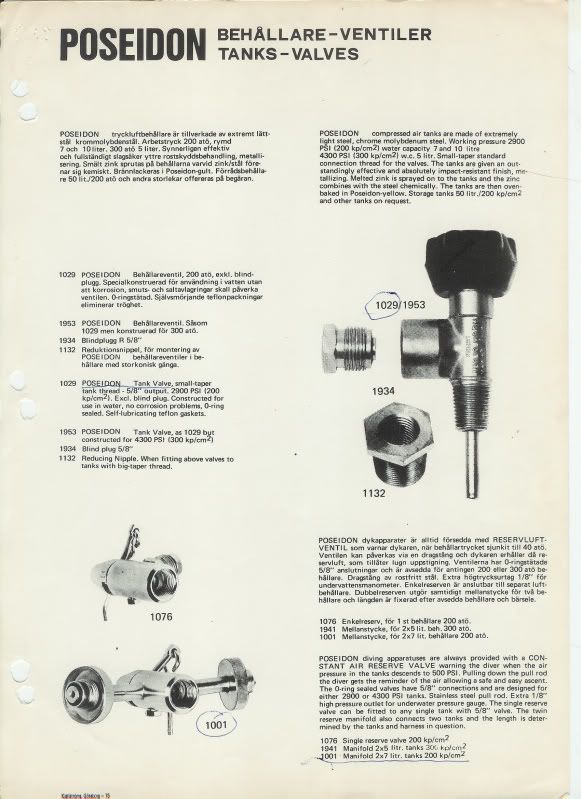

I don’t know the history of when the connection was first named DIN, but I have several catalogs from the 60’s and 70’s for Poseidon and Drager and neither calls the connection or the adapters as DIN.

In the early 70’s I bought a set of Drager tanks from 1957 with DIN valves and a set of Poseidon tanks with similar valve. I bought them from a merchant marine sailor in Puerto Rico. The only regulator available in this side of the pond with the threaded connection was the Poseidon. Which happen to be my favorite regulator at the time.

Below are a couple of Poseidon catalog pages from the 60’s or 70’s. Notice that the term DIN is not used anywhere. It refer to the 5/8” threaded connection… yes, the connection is not metric.

Here are my old Poseidon tanks with DIN valves. If you notice the valve on the left was replaced. The threaded connection was damaged on the original valve.

Here are my Drager tanks. The valve on the left was also replaced. I also replaced the tank bands and manifold with Poseidon parts. The original manifold did not use an O-ring. It used phenolic gaskets on the male 5/8” threaded fittings (DIN).

This is a recent picture of me using my Poseidon tanks with a Phoenix Royal Aqua Master with DIN connection.

Sorry for the long post.