Couple of weeks ago I got an old Bauer K14, which had spent 10 years at sea for an offshore company.

It was built in 1981, had a 7.5kW 3-phase engine with a manual star-delta switch and lots of rust.

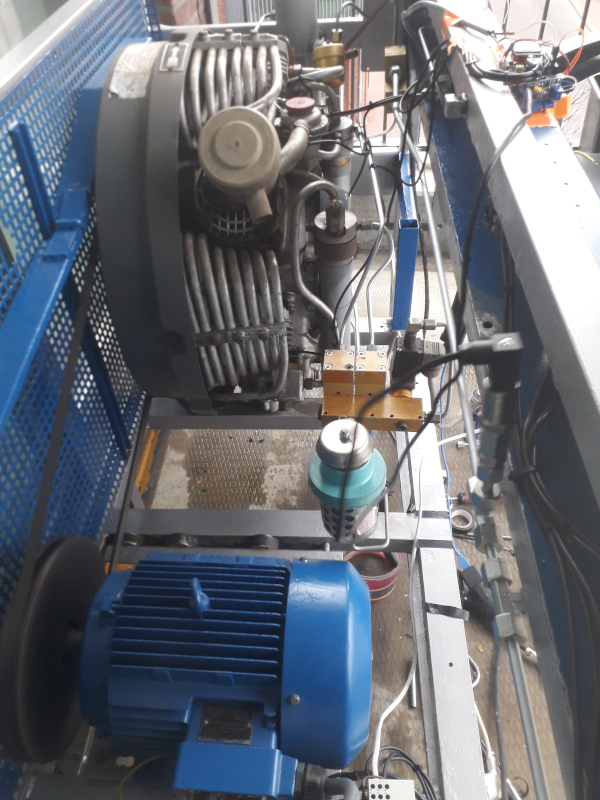

I cleaned it up, changed the engine for a 3.6kW 3-phase one, added a softstarter, automatic condensate drain, oil pressure sensor & switch, and a pressure maintenance valve.

Then I needed a control unit to operate the condensate drain, check the oil pressure switch and turn the compressor off once the maximum pressure has been reached.

I built it myself using an Arduino, small display, and a relay. And since components these days are dirt cheap, I also added temperature sensors which are mounted on each stage, and a Hall sensor to measure the rpm.

Turned out pretty neat. I just ran a test, filling a set of doubles from 25bar to 305bar. The oil pressure switch still needs to be set correctly:

It was built in 1981, had a 7.5kW 3-phase engine with a manual star-delta switch and lots of rust.

I cleaned it up, changed the engine for a 3.6kW 3-phase one, added a softstarter, automatic condensate drain, oil pressure sensor & switch, and a pressure maintenance valve.

Then I needed a control unit to operate the condensate drain, check the oil pressure switch and turn the compressor off once the maximum pressure has been reached.

I built it myself using an Arduino, small display, and a relay. And since components these days are dirt cheap, I also added temperature sensors which are mounted on each stage, and a Hall sensor to measure the rpm.

Turned out pretty neat. I just ran a test, filling a set of doubles from 25bar to 305bar. The oil pressure switch still needs to be set correctly: