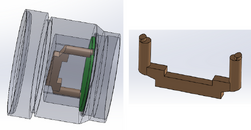

Hello, to achieve the rotational blocking of the printed circuit, I modeled and printed in 3D, in ABS, a small part of which you have a view on the drawing. I am attaching the STL file if you are interested. Good day

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cheap chinese video light review

- Thread starter vovanx

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

LeopoldToth

Registered

Hi,

What a great thread!

I have the same light that has some issues now.

Sometimes it does not turn on, so need to disconnect batteries a couple of times. Sometimes in full OFF mode there is a leak current to the white LEDs making them glow.

Did anyone have the glowing LED issue before?

I will disassemble it now (cool tools QRikard!) and maybe replace the witches too.

I'm not a big fan of reed switches (had the same ring-with-magnet solution on my DiY lamp), but more inclined towards a piezo switch even if I need a small circuit (Attiny or NE555 / 7555) to prolong the pulse.

What a great thread!

I have the same light that has some issues now.

Sometimes it does not turn on, so need to disconnect batteries a couple of times. Sometimes in full OFF mode there is a leak current to the white LEDs making them glow.

Did anyone have the glowing LED issue before?

I will disassemble it now (cool tools QRikard!) and maybe replace the witches too.

I'm not a big fan of reed switches (had the same ring-with-magnet solution on my DiY lamp), but more inclined towards a piezo switch even if I need a small circuit (Attiny or NE555 / 7555) to prolong the pulse.

Thanks, hope you get the tools to work nicely as well. For me they were great except the part to remove the buttons, pliers is an easier solution.Hi,

What a great thread!

I have the same light that has some issues now.

Sometimes it does not turn on, so need to disconnect batteries a couple of times. Sometimes in full OFF mode there is a leak current to the white LEDs making them glow.

Did anyone have the glowing LED issue before?

I will disassemble it now (cool tools QRikard!) and maybe replace the witches too.

I'm not a big fan of reed switches (had the same ring-with-magnet solution on my DiY lamp), but more inclined towards a piezo switch even if I need a small circuit (Attiny or NE555 / 7555) to prolong the pulse.

I'm worried about hearing leak currents. Had that on another cheap chinese light and the cause was electrogalvanic corrosion... The rear end of the casing was connected to minus on the battery and the aluminum head to plus... So the saltwater created a galvanic cell and the battery was used to dissolve the aluminum and generate hydrogen...

So measure if there is a voltage between the aluminum parts.

I went for reed because piezo was expensive and difficult to source. Especially without additional circuits.

So far no issues with my buttons but i recommend to unscrew the tail a millimeter for storage to avoid mishaps. Bonus of my reed solution is that i never needed to remove the main PCB (which was stuck (glued?) in my lamp) only the buttons and could solder directly on those.

LeopoldToth

Registered

Yes

// Are the button rings threaded or need to pop them out?

// Are the button rings threaded or need to pop them out?

LeopoldToth

Registered

There is a bit of a corrosion on the blue/red button, but not too much. There is a small leak around the button pin, might still be OK for a while with some lube. The water did not reach the switch panel though as the rubber plate is intact. The button is a bit sticky --> some grease will help.

The leak current is rather small, still hunting for the source of it. It starts around 1.1mA then after ~2 seconds (no scope, just an old multimeter) it goes down to 0.1mA. It is reproducible with batteries and with PSU as well.

The leak current is rather small, still hunting for the source of it. It starts around 1.1mA then after ~2 seconds (no scope, just an old multimeter) it goes down to 0.1mA. It is reproducible with batteries and with PSU as well.

Attachments

The button rings (transparent plastic) is threaded so just use some pliers to unscrew them, a piece of rubber can reduce risk of scratches (for the next person, you have figured it out alreadyYes

// Are the button rings threaded or need to pop them out?

Cant see your images but note that other users have drowned their lights by getting water between the rubber membrane and the button causing rust/corrosion and salt crystals which in turn pierce the membrane causing a full leak.

Issue is delayed with cleaning and some silicone grease but the deadline is approaching when your reach that state...

I haven't debugged these lights (lucky me so far) so cant help you more but please post your findings with pictures, might save someone later.

Note, for some reason i cannot see the images you just uploaded, they are just blank.

LeopoldToth

Registered

Thanks for the advice!

Something is wrong with the pictures, so Imgur here:

The main panel looks clean apart from some resin residuals. No burns, no shorts, wires are OK.

I will de-solder the button ribbons and maybe move the FET to the other position.

Btw, why there is only a single chip (dual FET there)? Is there a stronger light?

Something is wrong with the pictures, so Imgur here:

The main panel looks clean apart from some resin residuals. No burns, no shorts, wires are OK.

I will de-solder the button ribbons and maybe move the FET to the other position.

Btw, why there is only a single chip (dual FET there)? Is there a stronger light?

MikeHoncho

Contributor

Could you elaborate on a couple things? In the previous post to this one you mention gluing on the "PCB". What is a PCB and could you point it out in the picture above? Do you have a link to the actual reed switch you used? Do you have the 3d print file for the switch to share? Thanks and your work looks very clean. I think I'm going to go this route myself. I'm going to consider designing a magnetic slide switch (like you have) but mount it on the main body of the light and slide front to back. This will make it easier to access wit drysuit gloves and when on a camera tray. Thoughts?Found some photos on my phone. Purchased 14 mm reed relays with plastic encapsulation to minimize the risk of breaking it when bending the leads because you need to bend them quite aggressively to fit and to solder on the pads from the original switch (removed).

This is not the latest version of the magnet, i realized that it's better to mount the switch on the side to minimize the risk of turning it on by accident when setting it down. I use 1mm bungee cord to retract the magnet.

View attachment 862603

View attachment 862604

View attachment 862605

Short response. PCB = Printed Circuit Board so the green thing

I have never taken out the main one only the two tiny ones from the buttons. I only removed the push button and replaced it with a reed relay from amazon (faster than aliexpress). 14mm is the maximum length, shorter is better and sensitive is also good because even small magnets impact compass which i rely on heavily due to murky waters...

I purchased these. Only went for size, price and availability with fast shipping.

Clean away the resin, those are usually corrosive and could cause the conduction even if it should be unlikely but a FET i very sensitive to gate leakage. Use isopropanol and a gentle brush/cotton swab and make sure to rinse away all potential hairs... That might solve the glow if you are lucky.

I wouldn't move the FET, maybe reheat each leg in case there is a tiny hair inbetween.

I use drygloves exclusively, water is always cold here in the north...

I wanted to fit the slider completely on the head and make it slim so hence the round design. Still a work in progress, but works with dry gloves. Problem is to make something which is easy to use without risk of turning on by accident during transport on bumpy boat rides.

I have never taken out the main one only the two tiny ones from the buttons. I only removed the push button and replaced it with a reed relay from amazon (faster than aliexpress). 14mm is the maximum length, shorter is better and sensitive is also good because even small magnets impact compass which i rely on heavily due to murky waters...

I purchased these. Only went for size, price and availability with fast shipping.

Clean away the resin, those are usually corrosive and could cause the conduction even if it should be unlikely but a FET i very sensitive to gate leakage. Use isopropanol and a gentle brush/cotton swab and make sure to rinse away all potential hairs... That might solve the glow if you are lucky.

I wouldn't move the FET, maybe reheat each leg in case there is a tiny hair inbetween.

I use drygloves exclusively, water is always cold here in the north...

I wanted to fit the slider completely on the head and make it slim so hence the round design. Still a work in progress, but works with dry gloves. Problem is to make something which is easy to use without risk of turning on by accident during transport on bumpy boat rides.

MikeHoncho

Contributor

Ok so you did take the light apart to get access to the PCB for the switches, removed the original and installed the reed then reinstalled it all? I was under the impression you did it all through the switch hole but I'm assuming that is a little too small to work with.

Similar threads

- Replies

- 0

- Views

- 317

- Replies

- 44

- Views

- 5,371

- Replies

- 17

- Views

- 1,900