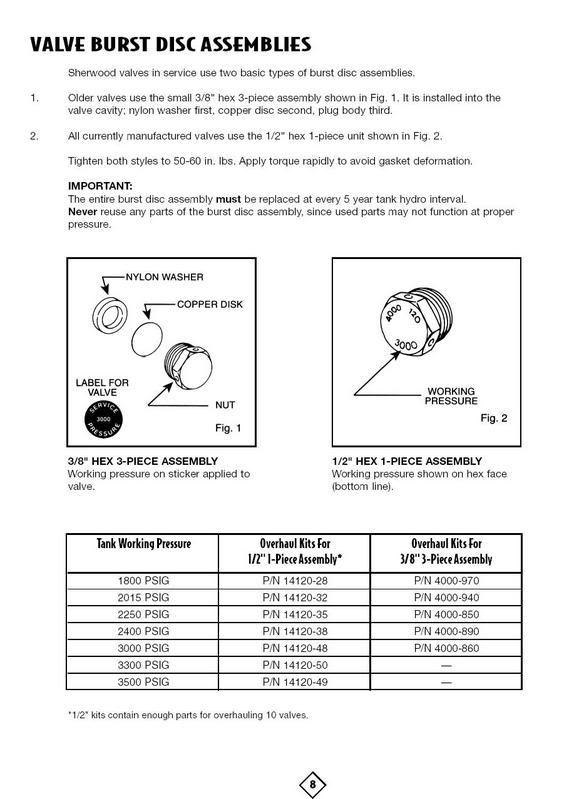

I used to have a pair of 1800 psi 45 cu ft steel tanks that my son used back when he was shorter than me. It was not uncommon for tank monkeys to treat them like regular AL 50's and fill them to 3000 psi even with the 1800 psi service pressure marked in red. Given that 3000 psi was the hydro test pressure for the tank this never made me very happy.However, most shops don't notice low pressure cylinders and end up filling them to 3000 like everything else. Subsequently, it's not unusual to see people use 3000/5000 disks. While this might be o.k., it's not approved!

Nor was I real thrilled on one occasion where I was charged for the first fill to 3000 psi plus the cost of replacing my "old" burst disc as well as the cost of a second fill to 3000 psi with the "new" 3000 psi service burst disc installed. That particular shop employee was pretty much an idiot.