If that's in reference to my post, read it again because I didn't say ALL positions.

It's a pleasure to respond to someone who writes exactly what they mean. Thanks for clarifying, and now I won't disagree with you regarding your comment about the special virtue of the Atomic when "looking up inverted" as a photographer.

For those who are just watching the play-by-play here, this is the single most fascinating thing about 2nd stages (to me, at least). It's why I like my D-400. It's why I like my Poseidon pneumatic. It's why I'm in awe of Atomic (and Aqua-Lung, and Scubapro) getting great performance out of a fundamentally flawed design. Here I will give complete and unadulterated credit to Mr. Peter Wolfinger, whose (doubtless copyrighted) pictures I comment from so shamelessly.

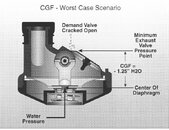

The chapter in Regulator Savvy on Case Geometry Fault is a light bulb moment of awakening for many of us. When you dive your Atomic and glance down at the bottom at some starfish:

...you must have your cracking effort set to over 1" water to keep your reg from freeflowing slightly, as the pressure of the sea water in which you dive wants to push in on your diaphragm, and initiate an unwanted breath. A pneumatic reg like the Poseidon has coaxial inhalation and exhaust valves, and there is less than 1/2" of height difference between the center of the diaphragm and the highest point on the exhaust valve in ANY position of diving. Add in the diminutive effort required to tilt the little servo valve and you now know why Jetstream divers get a little fanatic about their praise of their gear.

...you must have your cracking effort set to over 1" water to keep your reg from freeflowing slightly, as the pressure of the sea water in which you dive wants to push in on your diaphragm, and initiate an unwanted breath. A pneumatic reg like the Poseidon has coaxial inhalation and exhaust valves, and there is less than 1/2" of height difference between the center of the diaphragm and the highest point on the exhaust valve in ANY position of diving. Add in the diminutive effort required to tilt the little servo valve and you now know why Jetstream divers get a little fanatic about their praise of their gear.Well, it's the same for the Pilot, Air1 and D-series crowd:

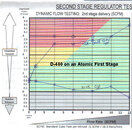

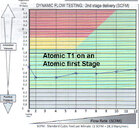

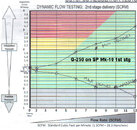

In a normal diving position, there's ZERO difference between the inhalation valve center and the highest point on the diaphragm. And when looking straight down (the worst case for the standard regulator geometry), there's about 0.25" difference in height between the two valves. That allows some pretty low cracking efforts. And the flow characteristics of the regulator with its variable Venturi adjustment are similarly impressive (even slightly better than the G-250 and one Atomic that I've tested):

In a normal diving position, there's ZERO difference between the inhalation valve center and the highest point on the diaphragm. And when looking straight down (the worst case for the standard regulator geometry), there's about 0.25" difference in height between the two valves. That allows some pretty low cracking efforts. And the flow characteristics of the regulator with its variable Venturi adjustment are similarly impressive (even slightly better than the G-250 and one Atomic that I've tested):

So I love all three! But I'll give diversteve a pass on this one. When looking up inverted (if I understand his comment correctly), his minimum cracking effort COULD be as little as 0.5" if he swam that way all the time.

But then, he'd freeflow slightly most of the rest of the time.

What I'm hearing him say is that with Atomic's standard case design (and its associated case geometry fault), adjusted to a max capability of (say) 0.8" cracking effort, when he's working hard upside down, the reg gives him a gentle freeflow that makes breathing effortless in that position.

All this just reinforces my basic belief that we need to buy the quality we can afford, and maintain it to it's best capability. And if we select special tuning (like 0.7" in a T1), we'll get some special side effects (like a gentle bubbling when looking straight down). It's all good! But when we argue here on SB (unlike diversteve and me) it's probably good to have some facts to back up your assertions.

The OP's thread was, "Are Atomics worth the cash?" Damned right they are! Just maybe not for some of the reasons cited. Seat-saver valves are a perfect example. It was mentioned as a negative, when it is actually a technological addition designed to address a specific problem, which it does very well! Okay, so you have some special considerations when you soak your regs afterward. I'll take that any day, when the benefit is that all I need to do is adjust cracking effort from time to time over a decade, instead of changing a seat every 1-3 years. Elan's got more money than I have, if she'd be willing to let a T1 sit on a stage bottle (if only it didn't have that darned seat-saver valve!). But I'm just picking on her by way of example. Some people like the new tech, some don't. It's all part of the law of unintended consequences.

Would I spend an extra $150 just to have an Aqualung ACD? Nah! I'll save it for my double-hose restoration, and pay a little attention when I disconnect my regs. If I had a bone to pick, it would be with technology that just makes scuba diving more foolproof.

Because that just allows more fools to dive.

Last edited: