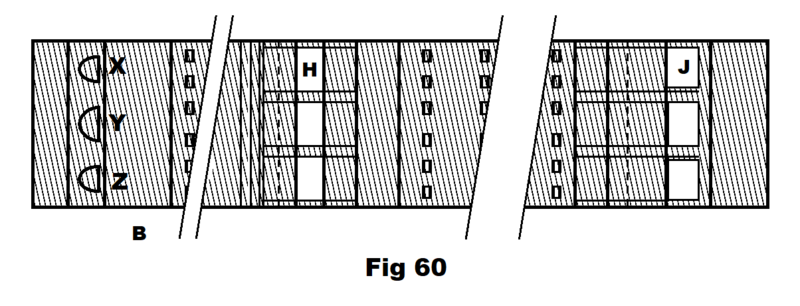

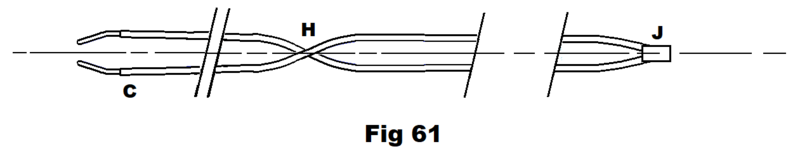

This foil contains an internal frame structure, represented by image Fig 60 shown from the edge and Fig 61 showing one face. It is made of a firm but bendable silicone or plastic. In the structure, a void exists in section Fig 61-H and Fig 61-J to accommodate intertwining the loop cable harnesses. The topography of sections H and J are shown in images Fig 67 and 68. The block attached to the loops inserts in the voids at Fig 68. The loops are inserted and crossed at Fig 68-H, then attached at Fig 61-X, Y, Z (also see Fig 66-K). The actual distance between sections can be adjusted to match the intended use of the fin.

For example; a longer fin could be used for distance cruising, and a shorter for sprint swimming.

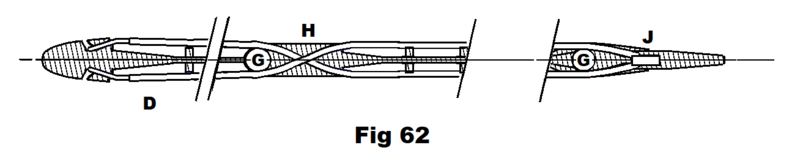

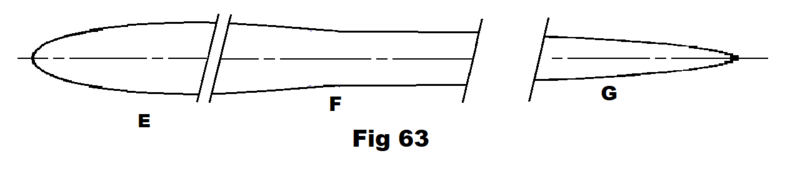

To make this foil, first the frame (Fig 61) is cast. Then the axle shafts are inserted into the tunnels located at Fig 63-G (two places). Next three cable sets are installed by weaving into the frame (Fig 63) and inserting the blocks (Fig 63-J).

Once woven into the structure the three cable assemblies Fig 62 will be anchored between the voids at Fig 61-J and the turnstile features at Fig 61-X, Y, Z. The X-Y-Z features are of two different sizes, two larger and one smaller on one side, and opposed by two smaller, and one larger on the opposite. This accommodates the variation in size of cable loops in each cable pair.

The profile shown Fig 63 represents the frame with the cable assemblies woven in

To weave a cable pair, first one of the cable loops are selected. On the side facing you, if there is a larger turnstile, choose the longer loop. Insert the exposed end into a void at Fig 61-J, then pull though and press the epoxy block in filling the void. Lay the cable loops forward, then insert the larger loop through the void at Fig61-H, pull through and forward then snap the cable end over the turnstile (Fig 61-X, Fig 66-K) to secure it. Then the shorter loop is inserted into the void at H from the other side, and inside and through the larger loop. Pulled through then forward secured to the turnstile similar to the first loop, but on the opposite side in all sections.

The same weaving process is applied to the other two cable pair assemblies. Then the tubes on the cables are slid down until butted up against the epoxy blocks.

Then the entire foil assembly is placed into a mold and a highly elastic silicone injected filling up all voids, and encasing the whole assembly. Because the cables are lubricated and inside the tubing, they will continue to be able to slide freely.

For example; a longer fin could be used for distance cruising, and a shorter for sprint swimming.

To make this foil, first the frame (Fig 61) is cast. Then the axle shafts are inserted into the tunnels located at Fig 63-G (two places). Next three cable sets are installed by weaving into the frame (Fig 63) and inserting the blocks (Fig 63-J).

Once woven into the structure the three cable assemblies Fig 62 will be anchored between the voids at Fig 61-J and the turnstile features at Fig 61-X, Y, Z. The X-Y-Z features are of two different sizes, two larger and one smaller on one side, and opposed by two smaller, and one larger on the opposite. This accommodates the variation in size of cable loops in each cable pair.

The profile shown Fig 63 represents the frame with the cable assemblies woven in

To weave a cable pair, first one of the cable loops are selected. On the side facing you, if there is a larger turnstile, choose the longer loop. Insert the exposed end into a void at Fig 61-J, then pull though and press the epoxy block in filling the void. Lay the cable loops forward, then insert the larger loop through the void at Fig61-H, pull through and forward then snap the cable end over the turnstile (Fig 61-X, Fig 66-K) to secure it. Then the shorter loop is inserted into the void at H from the other side, and inside and through the larger loop. Pulled through then forward secured to the turnstile similar to the first loop, but on the opposite side in all sections.

The same weaving process is applied to the other two cable pair assemblies. Then the tubes on the cables are slid down until butted up against the epoxy blocks.

Then the entire foil assembly is placed into a mold and a highly elastic silicone injected filling up all voids, and encasing the whole assembly. Because the cables are lubricated and inside the tubing, they will continue to be able to slide freely.