- Messages

- 20,794

- Reaction score

- 15,515

- # of dives

- I'm a Fish!

@Storker

This is a "normal" fill whip end over here. It's identical to the 300bar regulator ends. The same yoke adapters spin on and off we go. It's quite nice. I have never seen a 200bar fill end, and I have only seen a handful of 200bar regulators so it isn't a common thing over here. We use a lot of 200bar valves, but they are identical to our 300bar valves with the face shaved back 2 turns so we can use a yoke plug to convert it

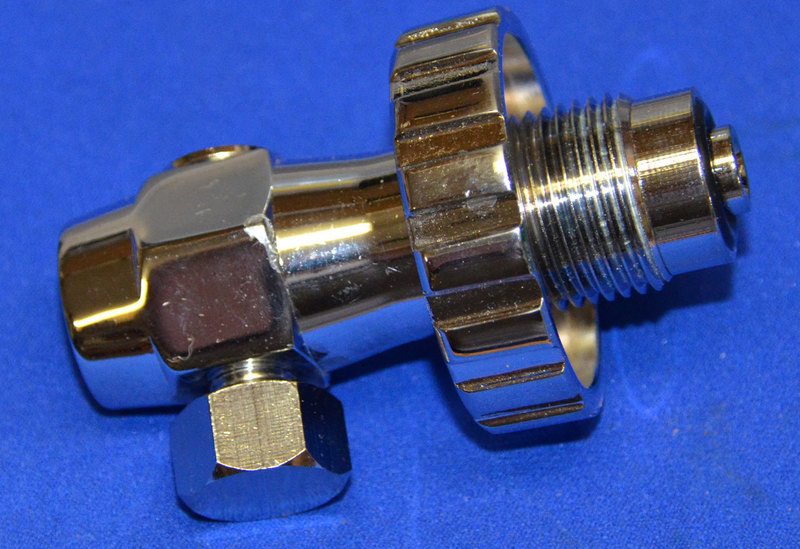

Din Filler with Screw Bleed - Upgraded

This is a "normal" fill whip end over here. It's identical to the 300bar regulator ends. The same yoke adapters spin on and off we go. It's quite nice. I have never seen a 200bar fill end, and I have only seen a handful of 200bar regulators so it isn't a common thing over here. We use a lot of 200bar valves, but they are identical to our 300bar valves with the face shaved back 2 turns so we can use a yoke plug to convert it

Din Filler with Screw Bleed - Upgraded