Inspired by @tbone1004 ’s handiwork with the cave country bench design from a while back, I decided to tackle the problem of cylinders sliding around the back of my cargo van by building a rack. The PVC pipe with O-ring arrangement (commonly available at dive stores) only works in confined spaces.

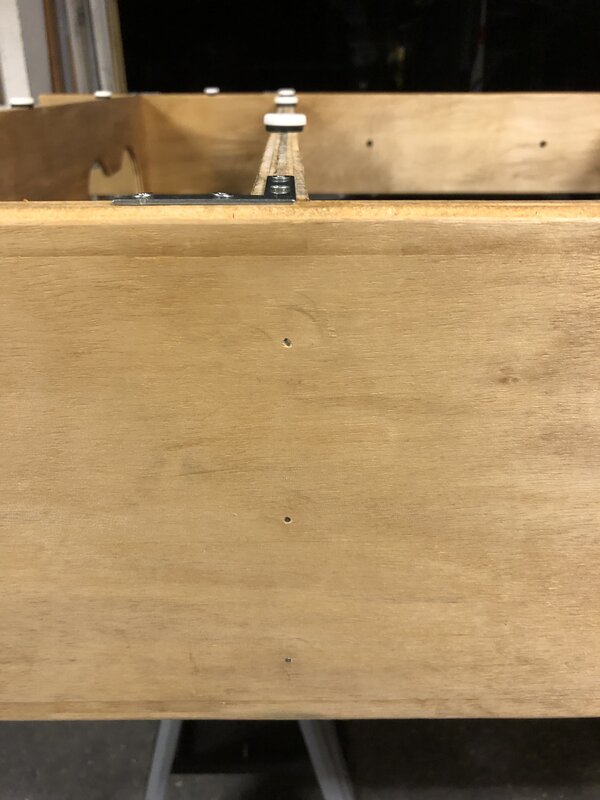

Mostly happy with v1.0 (square, dimensions never off more than 1/16”) but would assemble a few things differently were I to build a v1.1.

Mostly happy with v1.0 (square, dimensions never off more than 1/16”) but would assemble a few things differently were I to build a v1.1.