Internal Linings

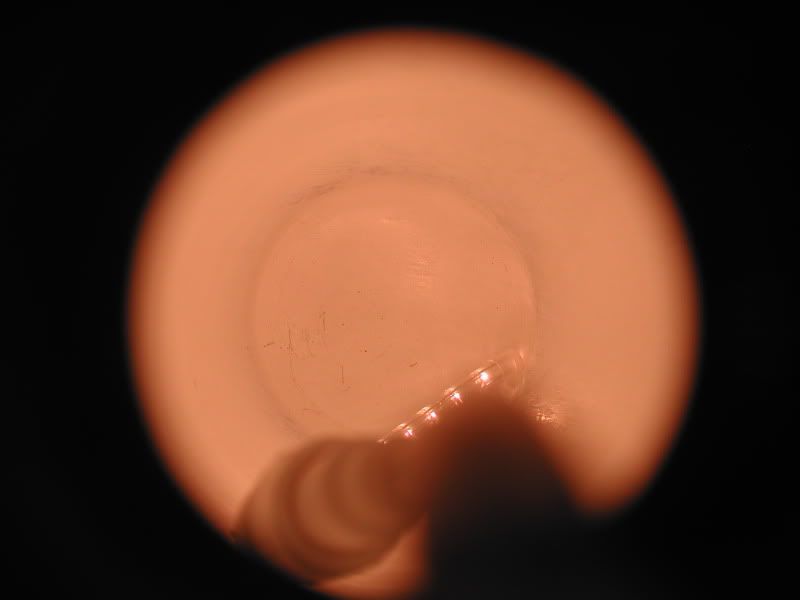

Cylinder inspectors are also faced with a special corrosion related problem

inside certain steel SCUBA cylinders. Several types of materials were placed in

cylinders to provide a protective barrier between the metal surface, moisture that

often entered the tank, and oxygen which is present at a high partial pressure.

None of those interior linings proved successful. In the late 1950s, U.S. Divers

Co. distributed cylinders lined with a white paint-like product. By the late 1960s,

brick red, brown and blue colored forms of epoxy were tried in steel cylinders.

Several problems arose. First, it was not possible to provide a liner

absolutely free of minuscule routes for water to reach the base metal. Also,

the epoxy did not expand at the same rate as the cylinder during the fill

process so cracks appeared in the coating. As a result, corrosion formed

beneath the liner, out of sight of the visual inspector. The CGA recommends

that interiorly lined cylinders be viewed carefully and, whenever corrosion

appears to have developed, the liner should be removed and the significance

of the corrosion assessed.

The removal of epoxy linings are, in themselves, a problem. Often, only

small portions of the epoxy have been loosened by rust while the remainder

is bonded firmly to the metal. Tumbling with aluminum oxide chips or equivalent,

for several hours, will usually remove the liner from corroded metal

but leave the bonded epoxy intact. Since corrosion has not formed behind

firmly bonded liner, over-zealous tumbling may not be necessary. Several

days of tumbling have failed to remove all traces of the epoxy.

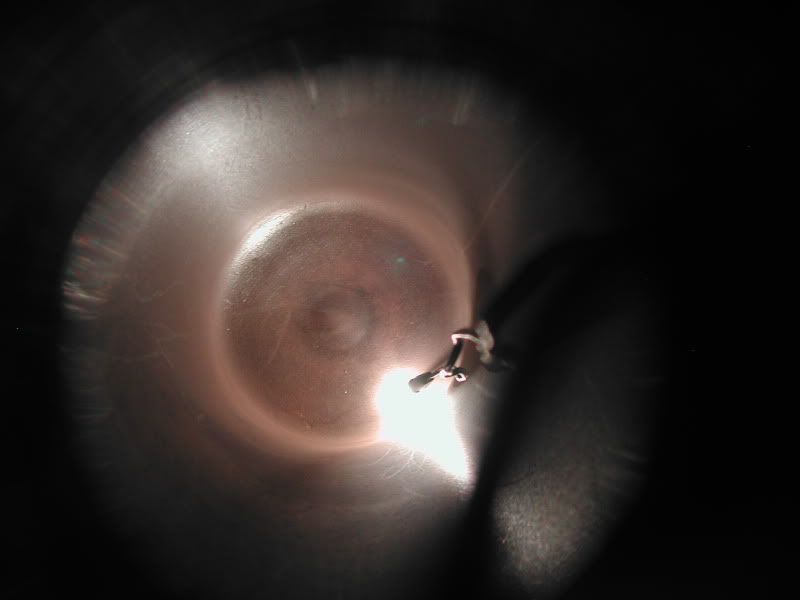

Infrequently, visual inspectors encounter cylinders to which the owner

attempted to apply some material as a corrosion inhibitor. Paint, epoxy, and

molten zinc, figure 8, have been found erratically adhering to interior walls.

Altered cylinders should be rejected because the possible damage may be difficult

to assess.

Linings mentioned above should not be confused with chemical treatments

performed by some aluminum cylinder manufacturers on their cylinder

interiors to inhibit corrosion. There are no lined aluminum SCUBA cylinders.

Alrock and Irridite, the dark gray or bright reflective surface respectively

are chemically produced forms of aluminum oxide intended to inhibit

further corrosion

32 INSPECTING CYLINDERS 4th Edition