You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vintage Tank find

- Thread starter CT-Rich

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Ghetto Diver

Contributor

For old steel tanks not one hint of rust. With K valves they'd make dandy IDs!

NOOOOOOOOOOOOOOOOOOO!

Nice find. I think you will find yourself getting into vintage diving if not already.

AfterDark

Contributor

NOOOOOOOOOOOOOOOOOOO!

Nice find. I think you will find yourself getting into vintage diving if not already.

Oh come on, they can always be changed back. I've got 2 USD steel 50 twins with K valves also have an old manifold to change them back. They are much more useful as singles. Rich's new/old tanks would also make good pony bottles separated. I've got nothing against vintage gear, I just got myself a 1970's Royal Aqua Master this AM on Ebay as a matter of fact. It looks a little rough on the top (chrome emblem) can but the rest looks good, hoses, mouthpiece, clamps, bottom can and yoke. I'll be getting a HPR2 for it and a silicone diaphragm after I disassemble and check it out.

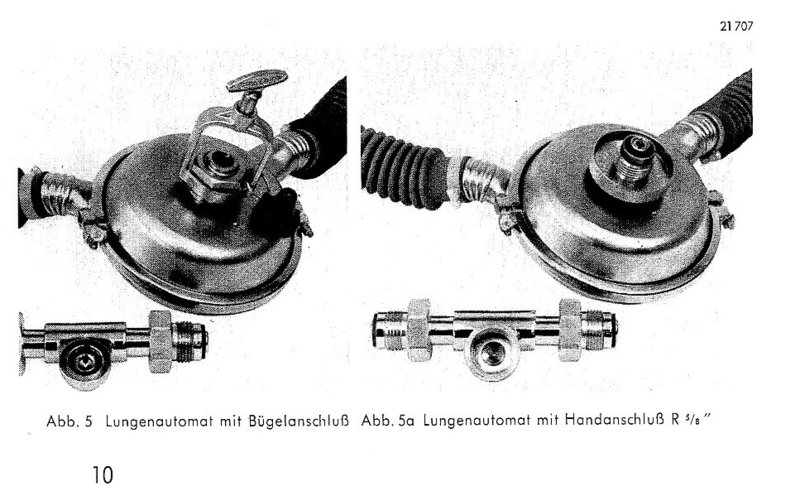

Hey Rich after I get my new/old double hose ready to dive, I'll be selling my Aqua Lung Jet Air double hose a nice mate for your new tanks. That reg is working fine just needs to be in the right spot on your back and the pressure differential does the rest. I've got 6 or 7 dives on it now. As a bonus I'll service it for you when it needs it, at cost of course.

I have an identical pair to those. As mentioned above, were sold by Drager. Mine were also born in 1957.

They appear to be galvanized , but I am afraid that they are only a grey paint. I ended up using galvanizing paint on mine and then covering with a white paint. The white paint was a major mistake.

Mine have some rust inside so they are basically out of commission. The neck is a small tapered neck a bit smaller than the US 1/2” pipe thread commonly found on some of the old ICC or DOT cylinders. They would be hard to tumble and impossible to use any of the wire brushes that I have.

Oh yes, They are definitely steel.

I am afraid that the idea of replacing the valves with US valves is out of the question. Actually, that is probably a good thing.

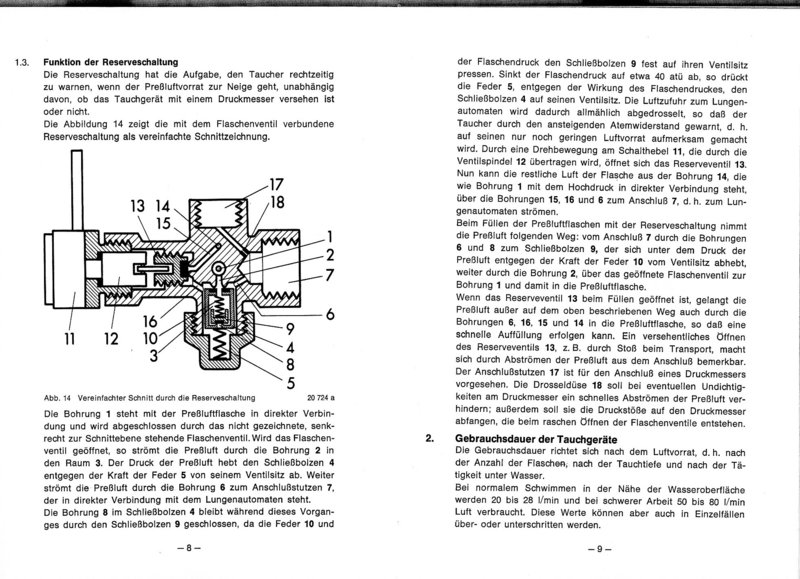

The cylinders actually have two independent DIN valves (they were not called DIN back then, but that is a different story). The center manifold just have two male DIN fittings, but they do not use O-ring seals. It uses a flat Phenolic gasket/ seal. There is no groove for an O-ring. My gasket has crumbled, but I have thought about replacing it with nylon flat washer to create a seal.

They can be separated even if they are full of air and used as single cylinders. Each valve is totally independent with a true DIN connection.

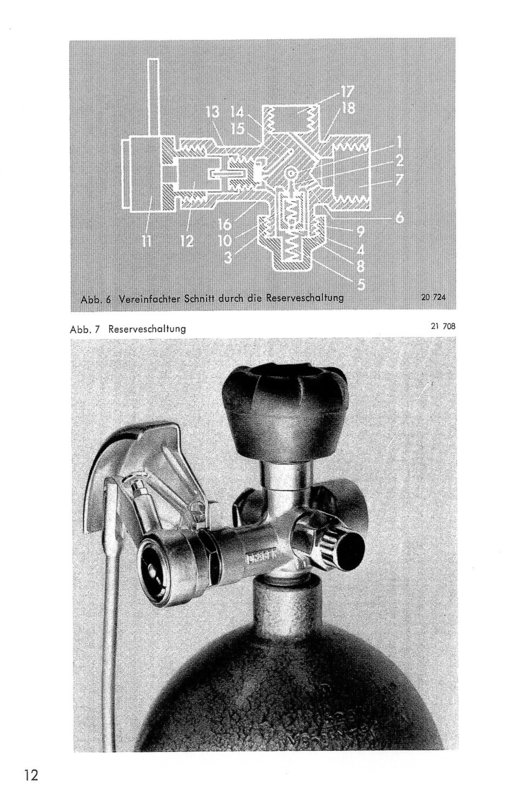

The reserve valve is another interesting piece. When you open the valve knob on the top the air flows past a spring loaded plunger that will hold back the air flow once the pressure goes down to a predetermined reserve pressure (I think mine was about 500 psi). Up to now, this description would be the same as in most reserve valves.

In a normal reserve valve the lever retracts that spring loaded plunger and the diver has access to the remaining air supply.

In this valve the lever open an independent by-pass valve that supplies the air to the diver. The by-pass valve has a very high pitch thread that allows the valve to fully open in just 1/4 turn of the lever.

What is very interesting is that the top valve knob can be fully closed, and you can get full tank air flow by just lowering the reserve lever. That has some interesting advantages, but obviously some major disadvantages. The reason for the lever guard is that just barely hitting the reserve lever can fully open the by-pass valve. You can lose a lot of air very quickly.

This is a very neat set of twin tanks and they are a lot of fun to dive. I have this set and a similar set that was made by Poseidon. They are both relatively negative in the water which is good up here.

I quit using them because servicing the narrow neck opening is a pain. I also don’t like having full set of tanks in my house without a burst disc (in case of fire).

Also getting them hydro tested is going to be a problem. It is going to be very hard to find a hydro test company in the US that will have a fitting with the appropriate threads. I only know of one person that have a custom made adapter fitting to hydro test these cylinders.

It is perfectly legal to hydro test them and the test facility can stamp the hydro date, but they are not allowed to stamp their DOT identification number normally stamped between the month and the year. Now the next challenge is to find a hydro test facility that has actually read the codes and actually knows that they can actually perform the test.

I have more information and I may even have some NOS parts for those valves, but the valves are probably OK.

They appear to be galvanized , but I am afraid that they are only a grey paint. I ended up using galvanizing paint on mine and then covering with a white paint. The white paint was a major mistake.

Mine have some rust inside so they are basically out of commission. The neck is a small tapered neck a bit smaller than the US 1/2” pipe thread commonly found on some of the old ICC or DOT cylinders. They would be hard to tumble and impossible to use any of the wire brushes that I have.

Oh yes, They are definitely steel.

I am afraid that the idea of replacing the valves with US valves is out of the question. Actually, that is probably a good thing.

The cylinders actually have two independent DIN valves (they were not called DIN back then, but that is a different story). The center manifold just have two male DIN fittings, but they do not use O-ring seals. It uses a flat Phenolic gasket/ seal. There is no groove for an O-ring. My gasket has crumbled, but I have thought about replacing it with nylon flat washer to create a seal.

They can be separated even if they are full of air and used as single cylinders. Each valve is totally independent with a true DIN connection.

The reserve valve is another interesting piece. When you open the valve knob on the top the air flows past a spring loaded plunger that will hold back the air flow once the pressure goes down to a predetermined reserve pressure (I think mine was about 500 psi). Up to now, this description would be the same as in most reserve valves.

In a normal reserve valve the lever retracts that spring loaded plunger and the diver has access to the remaining air supply.

In this valve the lever open an independent by-pass valve that supplies the air to the diver. The by-pass valve has a very high pitch thread that allows the valve to fully open in just 1/4 turn of the lever.

What is very interesting is that the top valve knob can be fully closed, and you can get full tank air flow by just lowering the reserve lever. That has some interesting advantages, but obviously some major disadvantages. The reason for the lever guard is that just barely hitting the reserve lever can fully open the by-pass valve. You can lose a lot of air very quickly.

This is a very neat set of twin tanks and they are a lot of fun to dive. I have this set and a similar set that was made by Poseidon. They are both relatively negative in the water which is good up here.

I quit using them because servicing the narrow neck opening is a pain. I also don’t like having full set of tanks in my house without a burst disc (in case of fire).

Also getting them hydro tested is going to be a problem. It is going to be very hard to find a hydro test company in the US that will have a fitting with the appropriate threads. I only know of one person that have a custom made adapter fitting to hydro test these cylinders.

It is perfectly legal to hydro test them and the test facility can stamp the hydro date, but they are not allowed to stamp their DOT identification number normally stamped between the month and the year. Now the next challenge is to find a hydro test facility that has actually read the codes and actually knows that they can actually perform the test.

I have more information and I may even have some NOS parts for those valves, but the valves are probably OK.

The little knob under the guard in the first picture (your Picture) is pulled out to adjust the stopping point on the reserve lever. Because the reserve is a high pitch screw it is hard to predict where it is going to stop when closed.

It is possible to totally disable the reserve, by removing the spring loaded plunger and removing the reserve lever, but that would be a crime.

There are more pictures below of a similar valve. Notice that some of the valve pictures are for straight threads with an O-ring seal. I wish I had that set-up instead of the tapered valves.

Your cylinders look like they are in very nice shape. Even the harness looks like new.

It is possible to totally disable the reserve, by removing the spring loaded plunger and removing the reserve lever, but that would be a crime.

There are more pictures below of a similar valve. Notice that some of the valve pictures are for straight threads with an O-ring seal. I wish I had that set-up instead of the tapered valves.

Your cylinders look like they are in very nice shape. Even the harness looks like new.

Here is a picture with my Poseidon tanks. The tanks are basically the same and the non-reserve tank valve is very similar to the Drager valve.

The reserve valve is in the center manifold in this case. This manifold also uses O-ring sealed DIN connections.

The reserve valve is in the center manifold in this case. This manifold also uses O-ring sealed DIN connections.

CT-Rich

Contributor

Thanks for all the information. I appreciate all the input about these tanks. The more I look at this rig, the more impressed I am. I have seen gear from the 1960s US that looks like absolute cheap junk compared to this stuff.Looks like the outside was galvanized, and is in perfect condition. They were made by IWK "Industrie Werke Karlsruhe" in Bexbach and are really good lightweight tanks made of very high quality steel.

Min Burst Pressure when new was specified to be over 800Bar, Hydro test Pressure is 300Bar but many divers regularily fill them to 260Bar cold and I haven't heard of people dieing because of these tanks exploding.

Really top quality tanks, usually sold to fire departments, for use above water, and the military. They were usually phased out after the fire departments upgraded to 300Bar systems.

The valves are commonly known as "Kleinkonische Ventile", the actual specification is "W 19,8 × 1/14 keg DIN 477 ISO 11363 – 17E".

For gods sake, don't cut these tanks and make bells/windchimes out of them - there are enough vintage divers who have been looking for a good set for over 5 years and pay cash.

Vintage divers will love them and dive them for another 50 or 75 years.

Should be worth a few hundred dollars to someone needing tanks for his antique Mistral or Royal Mistral regulator.

Michael

Don’t worry, I didn’t buy them to make bells, wind chimes or mailboxes. And I have no intention of breaking up the set. A side from a visual, they need to get hydro’d before they filled. This is its own problem because I would need a center that would have the right connector to match the tapered threading.

Someone mentioned the lack of a burst disk as a potential safety issue. My daughter pointed out that if was using a transfer whip off of my steel 120, I could store it at 400 psi.

The tanks are painted grey and it is flaking in some places. I tried out the harness last night and it is way too small for me, but in excellent condition. It is a cotton harness with some surprisingly modern features like multiple D-rings.

I was looking at the reserve rod and realized it is adjustable, although I am not sure how it works (or it may just set up weird). How it works with a head of pressure is yet to be seen.

The outside looks perfect. The big question is, what does it look like on the inside? As far as I can tell, the tanks has been sitting empty since 1980. A little moisture can do a lot in forty years.

Attachments

The top band is way too low on those tanks. If you adjust the bands and the harness correctly, it is possible that you may get enough webbing to fit, unless someone cut off a lot of webbing. My harness is the same and it has a lot of extra webbing.

You have to be very careful removing the valves. Do not allow anyone to put a wrench over the sides of the DIN fitting. It will roll the side walls of the DIN fitting in and it will make the valve totally useless.

The wrench has to be placed across the face of the DIN opening. I would also consider putting a temporary DIN insert to help support the DIN opening, but we didn't have those in the past so I didn't do it that way.

I also have a specific DIN wrench, but to be honest, I bought it years ago and I haven't actually used it. So I don't really know how well it works. The wrench actually screws into the DIN receiving socket.

The point is the DIN valves openings are relatively delicate and they have to be protected. About 40+ year ago I was able to replace a valve that was damaged at my LDS, but I seriously doubt that a new replacement could be found.

You have to be very careful removing the valves. Do not allow anyone to put a wrench over the sides of the DIN fitting. It will roll the side walls of the DIN fitting in and it will make the valve totally useless.

The wrench has to be placed across the face of the DIN opening. I would also consider putting a temporary DIN insert to help support the DIN opening, but we didn't have those in the past so I didn't do it that way.

I also have a specific DIN wrench, but to be honest, I bought it years ago and I haven't actually used it. So I don't really know how well it works. The wrench actually screws into the DIN receiving socket.

The point is the DIN valves openings are relatively delicate and they have to be protected. About 40+ year ago I was able to replace a valve that was damaged at my LDS, but I seriously doubt that a new replacement could be found.

AfterDark

Contributor

The top band is way too low on those tanks. If you adjust the bands and the harness correctly, it is possible that you may get enough webbing to fit, unless someone cut off a lot of webbing. My harness is the same and it has a lot of extra webbing.

You have to be very careful removing the valves. Do not allow anyone to put a wrench over the sides of the DIN fitting. It will roll the side walls of the DIN fitting in and it will make the valve totally useless.

The wrench has to be placed across the face of the DIN opening. I would also consider putting a temporary DIN insert to help support the DIN opening, but we didn't have those in the past so I didn't do it that way.

I also have a specific DIN wrench, but to be honest, I bought it years ago and I haven't actually used it. So I don't really know how well it works. The wrench actually screws into the DIN receiving socket.

The point is the DIN valves openings are relatively delicate and they have to be protected. About 40+ year ago I was able to replace a valve that was damaged at my LDS, but I seriously doubt that a new replacement could be found.

Good stuff Luis, I told him I'd take the tanks off the valves. I've got a 4' chain wrench that I can use along with some thick rubber sheet to protect the tanks. Normally it doesn't take much to get the tank moving. On my k valves I just tap the knob with a rubber mallet.

Similar threads

- Replies

- 31

- Views

- 3,442

- Replies

- 16

- Views

- 657

- Replies

- 29

- Views

- 3,254

- Replies

- 3

- Views

- 866