bj139

Contributor

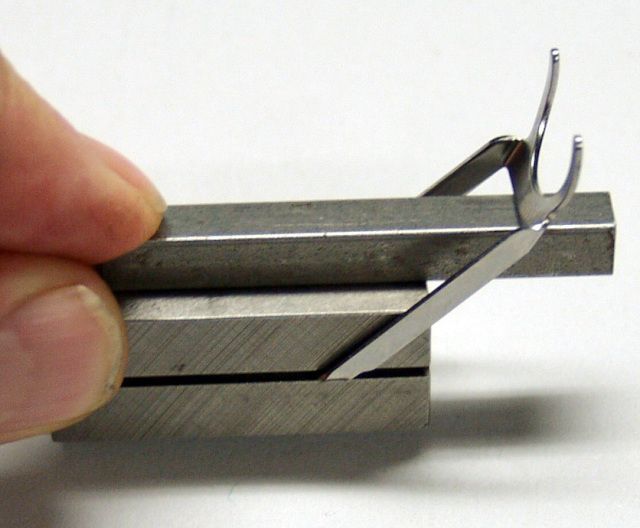

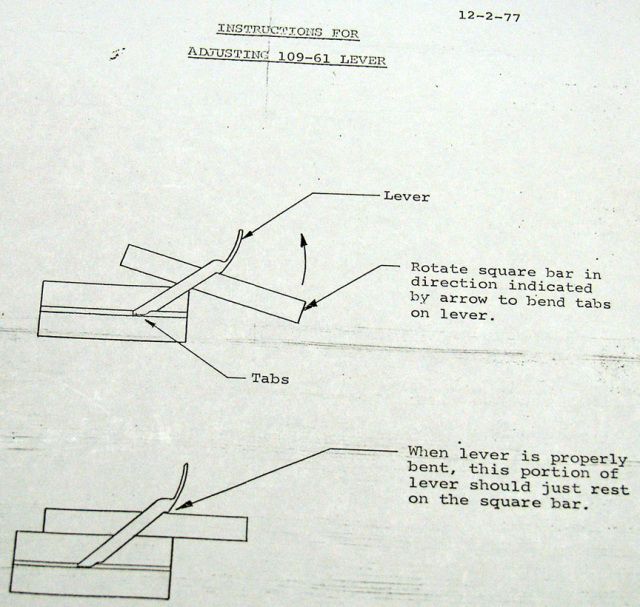

I dove with the R109 yesterday on a pony bottle. Adjusted fully out there was a light freeflow (small leak) coming from the mouthpiece. Adjusting the knob in all the way stopped the flow but breathing was hard. Adjusting it out it breathed OK. I left it turned in and continued the dive. I later noticed bubbles trickling from the mouthpiece. Opening then closing the knob seemed to stop this. Today I bent the ears down more since there is no free play between the diaphragm and lever indicating to me the diaphragm is providing some preload on the lever opposite to the direction of the mainspring. If this preload is relieved it should allow the orifice to be adjusted out more without freeflow. Maybe I better check the orifice for dents with a magnifier to eliminate that as a possible problem. Are you sure these are the best regs ever made? They sure seem to be temperamental.