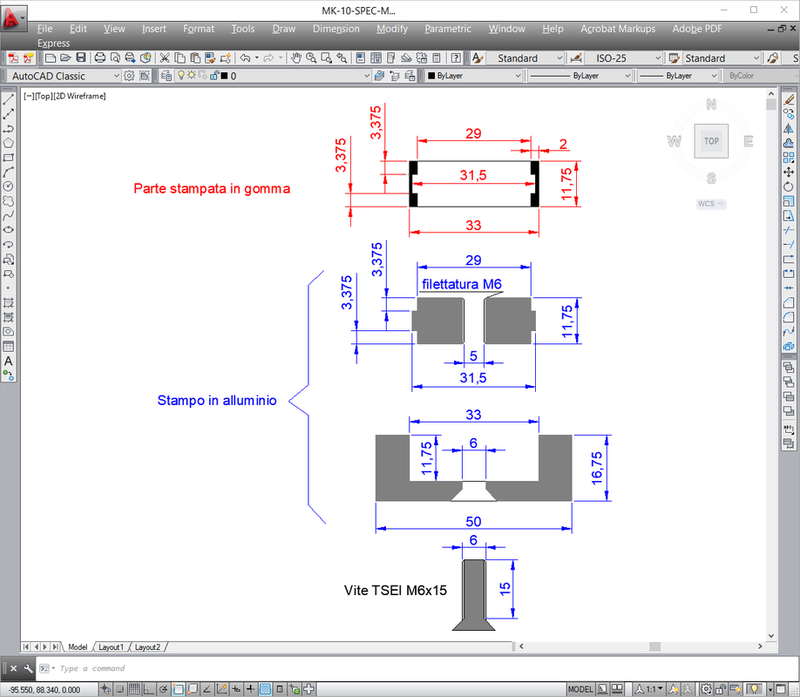

Here the revised drawing, after having reduced the diameters by 2mm:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SPEC Boots for MK10 and MK15 primary regs

- Thread starter lowviz

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Looks good!

@Angelo Farina If I'm reading the drawing correctly the wall thickness for the flexible part of the "reservoir" will only be .75mm Do you think that will be sufficient?

@Angelo Farina If I'm reading the drawing correctly the wall thickness for the flexible part of the "reservoir" will only be .75mm Do you think that will be sufficient?

The mold has been built, and yesterday I finally managed to bring it here at home (it was left in my office at the University, but yesterday I finally was allowed to go there and retrieve the parts, as an exception to the general lockdown in which are now).

Here you see it, first disassembled:

And here assembed:

Then I prepared an amount of two-component silicon rubber:

I know, the orange colour sucks, but that is what i managed to buy cheap on Amazon. Shops are closed here, and will stay closed at least another month... And I prepared too much of it, after filling the cup-like part of the mold and inserting the inner part, and locking the two parts together with the hex screw, this is the situation:

Now I have just to wait 24 hours. Then I will cut away the excess rubber with a sharp blade, and separate the two parts for extracting the SPEC boot.

Tomorrow I will post the results...

Here you see it, first disassembled:

And here assembed:

Then I prepared an amount of two-component silicon rubber:

I know, the orange colour sucks, but that is what i managed to buy cheap on Amazon. Shops are closed here, and will stay closed at least another month... And I prepared too much of it, after filling the cup-like part of the mold and inserting the inner part, and locking the two parts together with the hex screw, this is the situation:

Now I have just to wait 24 hours. Then I will cut away the excess rubber with a sharp blade, and separate the two parts for extracting the SPEC boot.

Tomorrow I will post the results...

And here the results of this first experiments. Here you see the mold as I did find it this morning. The silicon rubber did squeeze down covering it completely, eliminiating any air inclusion:

The excess was on the floor, of course. At this point I did use a blade to cut away this flat silicon disc:

And this was the result:

Then I removed the screw and pushed our the internal part of the mold:

Finally I pulled out the silicon boot from the mold:

The part required a minimum of finishing and cleaning, and here is it:

The rubber is very soft (30 shore), and incredibly elastic (it can be elongated at least three times without breaking), so it was easy to sleeve it on the body of the MK10 without any need of disassembling:

And here the boot properly fitted on the reg:

I am quite happy of the result, although there are a couple of small imperfections:

The excess was on the floor, of course. At this point I did use a blade to cut away this flat silicon disc:

And this was the result:

Then I removed the screw and pushed our the internal part of the mold:

Finally I pulled out the silicon boot from the mold:

The part required a minimum of finishing and cleaning, and here is it:

The rubber is very soft (30 shore), and incredibly elastic (it can be elongated at least three times without breaking), so it was easy to sleeve it on the body of the MK10 without any need of disassembling:

And here the boot properly fitted on the reg:

I am quite happy of the result, although there are a couple of small imperfections:

- The thickness is not uniform, probably I did not take care of centering properly the inner part of the mold

- The color sucks, I should try adding some pigment to the two-component mixture

drk5036

Contributor

Nice work! As someone new to the older scubapro regs, what’s the purpose of this boot?

It is for SPEC: Silicon protected environmental chamber.Nice work! As someone new to the older scubapro regs, what’s the purpose of this boot?

The whole volume of the reg inside the equalising holes is filled with silicon grease, so the piston is never in direct contact with water. This would cause some silicon paste to be squeezed out when the reg is pressurized, and when depressurized the lost silicon would be replaced by air (or water, if you depressurize underwater, which should never be done).

The rubber boot avoids that this silicon paste go around and is lost: it remains trapped in that annular channel grooved in the rubber boot, which is very soft and acts like a reservoir. When the reg is depressurized, the extruded silicon is sucked back in.

If the SPEC filling is done properly, there will be no air inside the reg body, hence all the moving parts and the dynamic O-rings will be completely protected from the sea water. This also reduces significantly the risk that water freezes in contact with the piston, locking it.

Some more info here: Environmental Seals Scubapro

Fantastic @Angelo Farina !

I don't have any recommendations for achieving the correct color. Black definitely is beautiful, especially on dive equipment.

To get a more consistent material, it might be helpful to degas one or both of the components in a vacuum chamber for about 2 hours before pouring.

My questions about the finished product are in regard to it's ability to properly seal the ambient chamber. Do you think the sealing band is tight enough to:

1. Prevent the sealant from escaping.

2. Prevent water from intruding.

Cheers,

Couv

I don't have any recommendations for achieving the correct color. Black definitely is beautiful, especially on dive equipment.

To get a more consistent material, it might be helpful to degas one or both of the components in a vacuum chamber for about 2 hours before pouring.

My questions about the finished product are in regard to it's ability to properly seal the ambient chamber. Do you think the sealing band is tight enough to:

1. Prevent the sealant from escaping.

2. Prevent water from intruding.

Cheers,

Couv

I like the color, I’ve never cared much about the MK 10 over any of the others, it’s a worthy project from the stand point of stuff to do and since it’s so stretchy you may want to reduce the size to address Couv’s concern.

Me; I would just buy an Atomic if I wanted a sealed piston (which I no longer do)

Me; I would just buy an Atomic if I wanted a sealed piston (which I no longer do)

The size had been already reduced, the boot is 2mm narrower than the reg, so it provides a very tight fit.

I do not see how silicon grease can escape. The problem is perhaps the opposite, it fits so well that it is perfectly wateproof.

So, If I do no manage the fill the inner space entirely, and some air volume remains trapped, when diving the boot will impede the water to go in, equalizing the pressure.

Regarding air trapped in the silicon rubber: before curing, this silicon rubber is incredibly liquid, and all bubbles go out the mix by themselves. The part I obtained is absolutely homogeneous.

Furthermore, I am locked at home since three weeks, and the scenario here is truly bad, I think I will be allowed to go out only in one month, or perhaps two. I cannot go to my lab at the University, and of course I do not have a vacuum pump here at home...

Regarding the Atomic: never seen one here in Italy.

Instead Scubapro regs are manufactured here, at Casarza Ligure, less than 2h form my home...

Which is where I was trained, 40 years ago, about assembling and servicing these regs.

Never used anything else, and I do not really see why should I change now, that I am beyond 60, and doing just a few rec or scientific dive each year, in a few meters of water...

So you could say: why do you need the SPEC boot? It is simple: my experience proofs that a properly packed SPEC reg does not need any maintenance for at least 5 years, whilst a not-sealed piston needs to be serviced once per year.

Now due to Covid-19 I have a lot of time for servicing all my regs while staying at home, and so I will do all of them and then for the next 5 years at least the first stage will not need to be opened again...

I do not see how silicon grease can escape. The problem is perhaps the opposite, it fits so well that it is perfectly wateproof.

So, If I do no manage the fill the inner space entirely, and some air volume remains trapped, when diving the boot will impede the water to go in, equalizing the pressure.

Regarding air trapped in the silicon rubber: before curing, this silicon rubber is incredibly liquid, and all bubbles go out the mix by themselves. The part I obtained is absolutely homogeneous.

Furthermore, I am locked at home since three weeks, and the scenario here is truly bad, I think I will be allowed to go out only in one month, or perhaps two. I cannot go to my lab at the University, and of course I do not have a vacuum pump here at home...

Regarding the Atomic: never seen one here in Italy.

Instead Scubapro regs are manufactured here, at Casarza Ligure, less than 2h form my home...

Which is where I was trained, 40 years ago, about assembling and servicing these regs.

Never used anything else, and I do not really see why should I change now, that I am beyond 60, and doing just a few rec or scientific dive each year, in a few meters of water...

So you could say: why do you need the SPEC boot? It is simple: my experience proofs that a properly packed SPEC reg does not need any maintenance for at least 5 years, whilst a not-sealed piston needs to be serviced once per year.

Now due to Covid-19 I have a lot of time for servicing all my regs while staying at home, and so I will do all of them and then for the next 5 years at least the first stage will not need to be opened again...

He may be half a world away, but there's clearly someone else who loves sealed pistons as much as @couv and I do.

That brings me to an old subject, which @lexvil will like...

My son and I are locked away here in NorCal, doing much as Angelo Farina is doing: slowly working through the piles of old regs as he prepares for going to IDC (now canx) and getting his certificates as a reg repair technician.

So we seal our Mk10 with a boot like Angelo's, courtesy of @raftingtigger , and he likes it. We work on a Mk10+ and disassemble and reassemble multiple times as we repolish the blunt end piston to eliminate an aggravating 7psi drift in IP over a 24-hour period. We did a few (eBay) Atomics and some lock right up while some need the same treatment: disassembly and re-polish subtle imperfections in the piston end to get a perfect seal.

So then we drag out a 35-year-old Mares MR22, and he does his first diaphragm. A quick polish on the removable seat, assembly by the manual, and bing! Perfect lockup, and what's more, ONE psi difference between 300 and 3000 tank pressure.

So he says to me, "Dad, I know you've been a piston guy your whole life, but why would you go to all the trouble of polishing that piston, and packing with lube, when we just did this reg in 15 minutes?"

I DON'T want to derail this wonderful thread, and will start a new one once I have a table of all the brand and results we've had so far during lockdown, but it did get me thinking, "Why don't I like diaphragms?"

And then we went on to a Mk17 I'd serviced a few months ago, just to compare balancing between full and empty tanks (8 psi ), and I saw that the secondary environmental diaphragm had acquired a bubble which only got worse on pressurization, despite my having done final assembly of that reg under pressure. And I thought, "Ahah! That's one reason I don't like diaphragms." I can fill a piston perfectly with goop, despite @Angelo Farina 's worry above:

), and I saw that the secondary environmental diaphragm had acquired a bubble which only got worse on pressurization, despite my having done final assembly of that reg under pressure. And I thought, "Ahah! That's one reason I don't like diaphragms." I can fill a piston perfectly with goop, despite @Angelo Farina 's worry above:

Now I can see that in a Deep6 reg, and quickly fix it. But the Mk17 has it hidden under a boot that protects the fragile environmental diaphragm, and in this case, I didn't know I had an issue.

Stay tuned for the soon-to-be-introduced 64th ScubaBoard thread on

PISTONS vs. DIAPHRAGMS !!

And now back to our regular programming...

That brings me to an old subject, which @lexvil will like...

My son and I are locked away here in NorCal, doing much as Angelo Farina is doing: slowly working through the piles of old regs as he prepares for going to IDC (now canx) and getting his certificates as a reg repair technician.

So we seal our Mk10 with a boot like Angelo's, courtesy of @raftingtigger , and he likes it. We work on a Mk10+ and disassemble and reassemble multiple times as we repolish the blunt end piston to eliminate an aggravating 7psi drift in IP over a 24-hour period. We did a few (eBay) Atomics and some lock right up while some need the same treatment: disassembly and re-polish subtle imperfections in the piston end to get a perfect seal.

So then we drag out a 35-year-old Mares MR22, and he does his first diaphragm. A quick polish on the removable seat, assembly by the manual, and bing! Perfect lockup, and what's more, ONE psi difference between 300 and 3000 tank pressure.

So he says to me, "Dad, I know you've been a piston guy your whole life, but why would you go to all the trouble of polishing that piston, and packing with lube, when we just did this reg in 15 minutes?"

I DON'T want to derail this wonderful thread, and will start a new one once I have a table of all the brand and results we've had so far during lockdown, but it did get me thinking, "Why don't I like diaphragms?"

And then we went on to a Mk17 I'd serviced a few months ago, just to compare balancing between full and empty tanks (8 psi

and there will be no lag in relative IP as I descend. But if that secondary diaphragm has acquired a bubble from repeated depressurization of a secondary seal that's only hand tight, I'll have exactly the same problem.If I do not manage to fill the inner space entirely, and some air volume remains trapped...

Now I can see that in a Deep6 reg, and quickly fix it. But the Mk17 has it hidden under a boot that protects the fragile environmental diaphragm, and in this case, I didn't know I had an issue.

Stay tuned for the soon-to-be-introduced 64th ScubaBoard thread on

PISTONS vs. DIAPHRAGMS !!

And now back to our regular programming...

Similar threads

- Replies

- 25

- Views

- 3,539

- Replies

- 25

- Views

- 4,969

- Replies

- 16

- Views

- 3,458

- Replies

- 1

- Views

- 3,432