vioch

Contributor

Want to replace my leaking Apeks exhaust valve with a SiTech one and have a question:

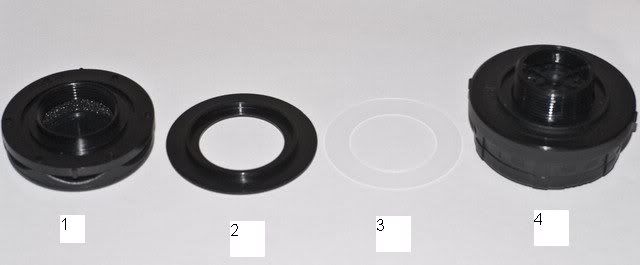

Valve consists from 4 parts: inner, two in the middle and outer

On what suit sleeve side (inner\outer) should be two middle parts installed?

Valve consists from 4 parts: inner, two in the middle and outer

On what suit sleeve side (inner\outer) should be two middle parts installed?