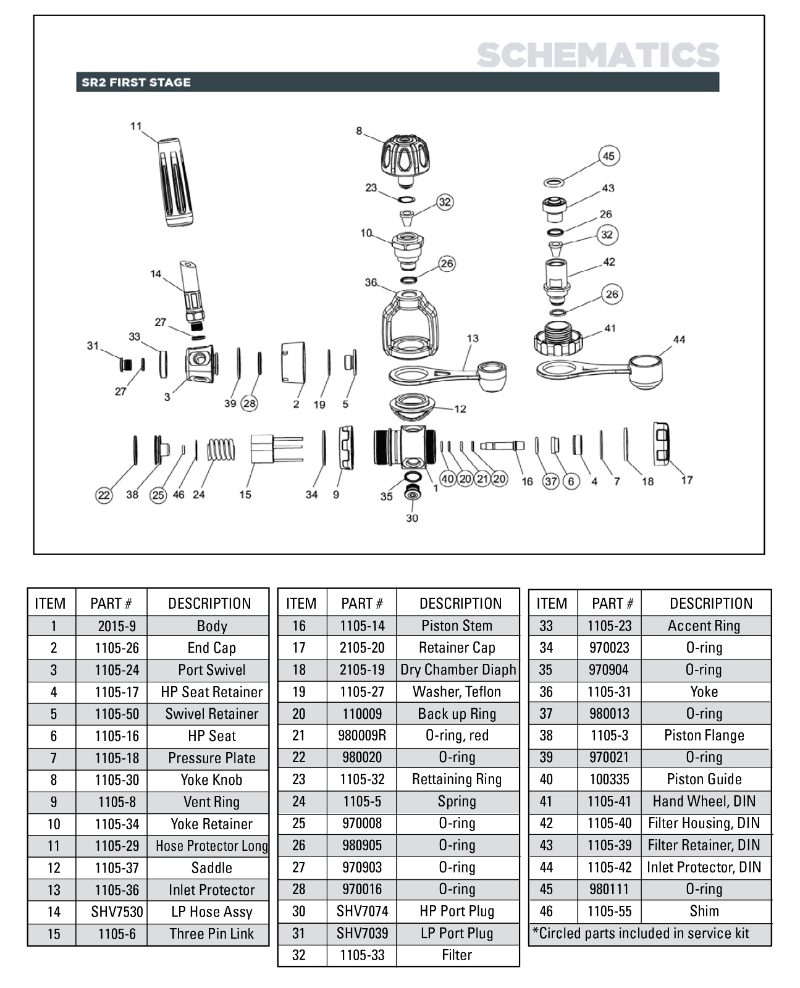

I'm reviewing Sherwood's first stage and I found the information is not much. For example, from their website, they mentioned "Two-piece piston for precise optimum balance", but I can't find any explanation how that is going to help precise IP on the internet. Is it because they make a piston stem that has different diameter on each sides (like overbalanced)?

Also, some of the articles mentioned that they have the "dry sealed spring chamber" feature. Is that the same thing as their air bleed system?

Also, some of the articles mentioned that they have the "dry sealed spring chamber" feature. Is that the same thing as their air bleed system?