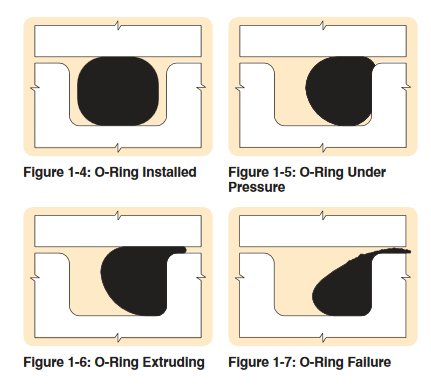

If you guys are interested in orings, I suggest you read Parker's Oring manual (on line). They have some excellent information on how oring seals work. They suggest considering an oring to be like an elastic, very thick liquid that "flows" into the space around it when forced to do so by pressure but it can't flow past a give gap, creating a seal. Wheather or not the oring will flow through the gap (extrude) is determined by the " viscosity" of the oring (durometer), the differential pressure across it and the width of the gap. They also discuss back up rings and dynamic vs static, something which most people don't really understand. Very worthwhile reading for anyone who wants to understand how a dive regulator works since orings are a vital part of them......or nerds who just love to know how stuff works.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scubapro MK20 - shredded piston O-ring

- Thread starter fmerkel

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

fmerkel

Contributor

That's not a manual, it's a college education! The first explanatory section was pretty readable and understandable, at least for me. The point about extrusion under pressure was conveyed quite well.

Good link. Thanks.

E. In either static or dynamic O-ring seals under high pres-

sure the primary cause of seal failure is extrusion of the

seal material into the piston-cylinder clearance. The

major factors effecting extrusion are fluid pressure, seal

hardness and strength, and piston-cylinder clearance.

F. Dynamic seals may fail by abrasion against the cylinder

or piston walls. Therefore, the contacting surfaces should

be polished for long seal life. Moving seals that pass over

ports or surface irregularities while under hydraulic pres-

sure are very quickly cut or worn to failure.

Good link. Thanks.

E. In either static or dynamic O-ring seals under high pres-

sure the primary cause of seal failure is extrusion of the

seal material into the piston-cylinder clearance. The

major factors effecting extrusion are fluid pressure, seal

hardness and strength, and piston-cylinder clearance.

F. Dynamic seals may fail by abrasion against the cylinder

or piston walls. Therefore, the contacting surfaces should

be polished for long seal life. Moving seals that pass over

ports or surface irregularities while under hydraulic pres-

sure are very quickly cut or worn to failure.

Last edited:

Similar threads

- Replies

- 9

- Views

- 911