Hi, I was reading this board and have learned a ton. I'm also looking for manuals and/or videos for the servicing a scuba pro mk11, R395, and a mares rover EM250(?). Sure appreciate it! I'm very interested in learning to do my own gear. I'm new to this board but not to diving

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ScubaPro MK11, R395 and R295 service manuals

- Thread starter stepfen

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Messages

- 17,700

- Reaction score

- 9,963

- Location

- Somewhere between here and there

- # of dives

- 2500 - 4999

DM me your email address and I'll get SP manuals to you.Hi, I was reading this board and have learned a ton. I'm also looking for manuals and/or videos for the servicing a scuba pro mk11, R395, and a mares rover EM250(?). Sure appreciate it! I'm very interested in learning to do my own gear. I'm new to this board but not to diving

Talk to @lowwall or @Zef for the mares.

We all hunger for tips and instruction, and YouTube has become a rich repository of both good and really bad information.

Please don't attempt to service your gear by just following a video! Four examples from the above.

Mk11 disassembly:

1) At 4:40, the tech spends 30 seconds digging at the edge of the diaphragm with a sharp brass pick to remove it. Yes, brass is softer than chrome, but I'll bet there are now scratches in this critical sealing land.

2) At 6:02, the tech uses just the tips of a too-small adjustable wrench to remove a pre-loosened yoke bolt. There's no way he could have done this with a salt encrusted bolt after two years, without spalling the hex flats of the bolt.

3) He completely omits the removal, inspection and dressing of the volcano! Hello! Schematic?

Mk11 Assembly:

4) At 3:28, he hand-twists the diaphragm clamp onto the body. This is the critical seal of the reg, which is spec'ed in previous versions of the schematic, as well as confidential service tech videos, at over 25 foot-pounds! And he torqued it in his hands? No way! That diaphragm is going to blow loose at the first pressurization!

Now it's maybe not his fault. The latest maintenance manual says this:

"13. Lubricate slightly the threads before screwing the diaphragm retainer by hand in the body.

14. Fix the field handle tool again in one of the HP ports and secure the tool in a vice. Use the universal tool and tighten snug the diaphragm retainer on the body

WARNING: If the diaphragm is not properly secured by a firm tightening, there is a risk of the diaphragm coming off its groove resulting in a heavy air leak that could endanger the diver's life."

"Tighten snug"??? WTH does that mean?

And there's no torque notation on at least one schematic. A critical omission by Scubapro, that is infuriatingly typical of their most recent publications. Thank God René Dupré is there to guide new techs. At least they fixed that five years later. But the service manual still sucks.

Any tech who has been trained in the basics would not have done any of the above. Don't just watch a video. Buy Reg Savvy. Talk to several others before taking this on. Get some training.

This is one time when the mantra we love to mock is actually true: "this is life support equipment".

Please don't attempt to service your gear by just following a video! Four examples from the above.

Mk11 disassembly:

1) At 4:40, the tech spends 30 seconds digging at the edge of the diaphragm with a sharp brass pick to remove it. Yes, brass is softer than chrome, but I'll bet there are now scratches in this critical sealing land.

2) At 6:02, the tech uses just the tips of a too-small adjustable wrench to remove a pre-loosened yoke bolt. There's no way he could have done this with a salt encrusted bolt after two years, without spalling the hex flats of the bolt.

3) He completely omits the removal, inspection and dressing of the volcano! Hello! Schematic?

Mk11 Assembly:

4) At 3:28, he hand-twists the diaphragm clamp onto the body. This is the critical seal of the reg, which is spec'ed in previous versions of the schematic, as well as confidential service tech videos, at over 25 foot-pounds! And he torqued it in his hands? No way! That diaphragm is going to blow loose at the first pressurization!

Now it's maybe not his fault. The latest maintenance manual says this:

"13. Lubricate slightly the threads before screwing the diaphragm retainer by hand in the body.

14. Fix the field handle tool again in one of the HP ports and secure the tool in a vice. Use the universal tool and tighten snug the diaphragm retainer on the body

WARNING: If the diaphragm is not properly secured by a firm tightening, there is a risk of the diaphragm coming off its groove resulting in a heavy air leak that could endanger the diver's life."

"Tighten snug"??? WTH does that mean?

And there's no torque notation on at least one schematic. A critical omission by Scubapro, that is infuriatingly typical of their most recent publications. Thank God René Dupré is there to guide new techs. At least they fixed that five years later. But the service manual still sucks.

Any tech who has been trained in the basics would not have done any of the above. Don't just watch a video. Buy Reg Savvy. Talk to several others before taking this on. Get some training.

This is one time when the mantra we love to mock is actually true: "this is life support equipment".

Wow!! Thanks so much for the help. I just signed up and need a minumum of 5 posts before I can DM. So this makes post #2.

Thank you for the warnings too. I'm very mechanical and plan to practice on "junkers", as stated in this thread.

One more thought, because I'm so excited about this.... I found a sea horse in Grand Cayman!! Several have told me that this is rare. thanks for letting me share.  Post #4

Post #4

We all hunger for tips and instruction, and YouTube has become a rich repository of both good and really bad information.

Please don't attempt to service your gear by just following a video! Four examples from the above.

Mk11 disassembly:

1) At 4:40, the tech spends 30 seconds digging at the edge of the diaphragm with a sharp brass pick to remove it. Yes, brass is softer than chrome, but I'll bet there are now scratches in this critical sealing land.

2) At 6:02, the tech uses just the tips of a too-small adjustable wrench to remove a pre-loosened yoke bolt. There's no way he could have done this with a salt encrusted bolt after two years, without spalling the hex flats of the bolt.

3) He completely omits the removal, inspection and dressing of the volcano! Hello! Schematic?

Mk11 Assembly:

4) At 3:28, he hand-twists the diaphragm clamp onto the body. This is the critical seal of the reg, which is spec'ed in previous versions of the schematic, as well as confidential service tech videos, at over 25 foot-pounds! And he torqued it in his hands? No way! That diaphragm is going to blow loose at the first pressurization!

Now it's maybe not his fault. The latest maintenance manual says this:

"13. Lubricate slightly the threads before screwing the diaphragm retainer by hand in the body.

14. Fix the field handle tool again in one of the HP ports and secure the tool in a vice. Use the universal tool and tighten snug the diaphragm retainer on the body

WARNING: If the diaphragm is not properly secured by a firm tightening, there is a risk of the diaphragm coming off its groove resulting in a heavy air leak that could endanger the diver's life."

"Tighten snug"??? WTH does that mean?

And there's no torque notation on at least one schematic. A critical omission by Scubapro, that is infuriatingly typical of their most recent publications. Thank God René Dupré is there to guide new techs. At least they fixed that five years later. But the service manual still sucks.

Any tech who has been trained in the basics would not have done any of the above. Don't just watch a video. Buy Reg Savvy. Talk to several others before taking this on. Get some training.

This is one time when the mantra we love to mock is actually true: "this is life support equipment".

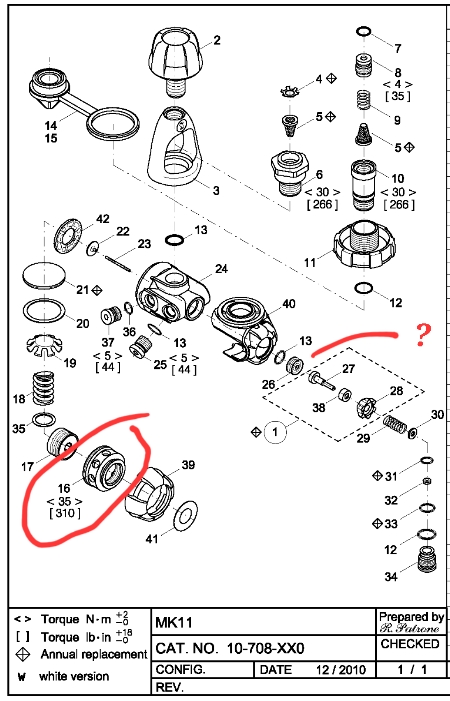

View attachment 782259

Just a note that those were not my videos, and I do not specifically or otherwise endorse using them as a source of information for performing maintenance. I especially do not endorse using a hemostat/surgical clamp in place of a wrench/nut driver. The requestor asked for manuals/videos and I just wanted to oblige them with what was readily available on the interwebs.

-Z

Can anybody tell what is the purpose of the thin teflon-like shim between the cap and the membrane holder in R295? I kind of ruined one on a regulator bought from ebay. The whole regulator had a nasty mold odor that wouldn't go away, so I finally resorted to immersing the parts in boiling-hot water with dish soap and sodium bicarbonate. While the rest of the parts behaved, the thin white shim warped instantly.

Is it just a friction-reduction thingy that one can live without, can I cut another one from a thin PE sheet? And also, what can I do to get rid of the smell, because now it's basically unusable.

Is it just a friction-reduction thingy that one can live without, can I cut another one from a thin PE sheet? And also, what can I do to get rid of the smell, because now it's basically unusable.

Similar threads

- Replies

- 8

- Views

- 207

- Replies

- 2

- Views

- 328