I understand, but it's a pretty substantial difference. Only pumping when ambient temps are lower makes a lot of sense on paper (to me). For instance, my filter is rated at 13,000 cf @ 80F OR 20,000 cf @ 68F. That's a pretty significant difference and technically means that going lower than 68F will yield even more from the filter. Just between those two temps alone is the difference of filling 70 HP 100's from empty to full. For me that's quite a bit of diving.That’s at ambient pressure and freezing to super hot we’re talking modest changes in temp and, at pressure. At scuba pressures we’re talking grains per lb.

Just for anyone following those temps are what the filter "see's", so it would need to be 50F-55F ambient to get the rated 20,000 cf because the filter stack would get heat bleeding from the compressor (which can be anywhere from 10F-18F depending on compressor and where you get your information)..

I am only using the compressor for my personal use, I am fortunate in the fact that I live in a somewhat cooler climate in the North East. I can choose to fill tanks / bank bottles on cooler days. I monitor with the spreadsheet. I set a timer when I start the compressor and stop it when done, always rounding up to the nearest 15 min segment.The problem is how to monitor it. There is no good reliable way to monitor the moisture vs the cost of cartridges so the recommendations are based off worst case, 95 ambient and the loss of cartridge life is ultimately worth it given all the other costs involved. Most cartridges give excellent output vs cost so hours are the best indicator to go by. If you are keeping the ambient extra low and wanted to risk using cartridges longer, I guess it wouldn’t be that risky but for the cost of a cartridge, doesn’t seem worth the savings.

I understand this wouldn't really work for a shop, especially in a warmer climate, but it works for me (they'll just replace filters more often). Because I run it this way my filter lasts me for the better part of 2 years. Because it's a Rix I'm only really concerned about moisture as there is no oil in the compressor. Even at the 18 month mark when i changed my last filter 1/2 of the moisture indicator strip hadn't turned yet (I don't know how accurate they are so I changed it anyway).

My tanks are always dry when I open them, and this works out to about $27 / year in filters.

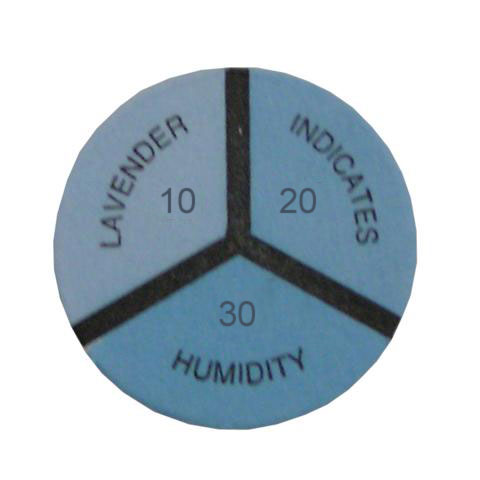

So there is a sight-glass type gizmo (H20 Visual Indicator) that is supposed to change color when moisture is detected. For the Rix, am I safe in monitoring that and if it doesn't turn color, I should be good?

View attachment 803487

I have one installed. I never look at it. I really need to pull it out and get it blue again. If you do get one (wouldn't hurt) and it does turn from blue to white you can use a hair dryer or equivalent to change it back an re-use, no need to buy multiples. They last for years (so I've been told).

Get the 10 / 20 / 30 don't get the 20 / 40 / 60, they're worthless. With the 10/20/30 you'd want to change filters as soon as you see any change, but it should really be your last resort hail mary effort. Hours on the filter or the spreadsheet should be your 1st line of defense (but I guess it's nice to have some sort of sanity check in line). I have my setup pretty much exactly as it is in the diagram.

Moisture Indicator Disk - August Industries LLC

This moisture indicating disc is for our visual indicators as well as many others. This disc is designed to show the relative humidity in a progressive scale. As 10 percent relative humidity is reached, the pie shaped section marked “10” will change color to pink. The same for 20 and 30. This...