beanojones

Contributor

- Messages

- 3,204

- Reaction score

- 350

Again, diving gear is designed to tolerate water.

It is is not. Minor corrosion on the filter of the first stage (for instance) causes dramatic decreases in performance. So does flooding the first stage, and flooding a second stage.

There are wet bits and there are dry bits. If you get the dry bits wet, they do not perform as they should.

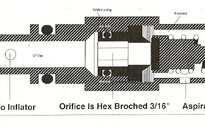

In the case of an inflator, you don't breathe off it, so you are not as aware of loss of performance. There are two very different inflator designs: the tire valve kind, and supply rods with O-rings kind. The tire valve bits are remarkably hardy. They hold the air in your car tires for years, even if they are uncapped and exposed to road salt etc. So they last longer than the inflators that have Orings on their supply rods. The Oring'd supply rod inflators (like OMS, Dive Rite, Halcyon, etc and the separate ScubaPro type) are the result of a design choice that recognizes that as hardy as those tire valve inflators are, they simply do not provide enough air flow at deeper depths. But there is a (to me) big tradeoff: they fail at at much, much higher rates when they are constantly flooded. It does not matter if you rinse it. There are moving parts meant to seal against clean filtered air, not water with the usual particulate load water carries. Rinsing it out might dilute the salt. It won't get rid of the particulate load the water (even the rinse water) carries into it.

Best practice: Don't disconnect.

Second best practice: Cap it like you would your first stage.

Anything else is making the gear work in a way that it is not designed to work. Because most inflators use incredibly hardy tire valve cores in them, you might not suffer much of a consequence. But if you use the kind that have O-rings on a supply rod, it will fail from being flooded, eventually.

**Note: ALL inflator hoses also have a tire valve in them to shut off air when the inflator is disconnected and the tank valve is open.. So the actual performance benefit of the supply rod with O rings kind of inflator is up for grabs since it is restricted by a tire valve in the inflator hose anyway.