Avonthediver

Contributor

I did the whole Q&A e-mail last night to find out a little info on how in the future one might buy a Kraken, and Bryan sent this

I will have one when the time comes and I really do love that red its just bad ass! This is just such an amazing project bringing the past alive for a new generation, who I might add has never had much if any contact with our history. I am just getting into the vintage thing so this to me is the right time to get involved!

Argonaut Kraken FAQ

You can find 99% of the information about it in two places.

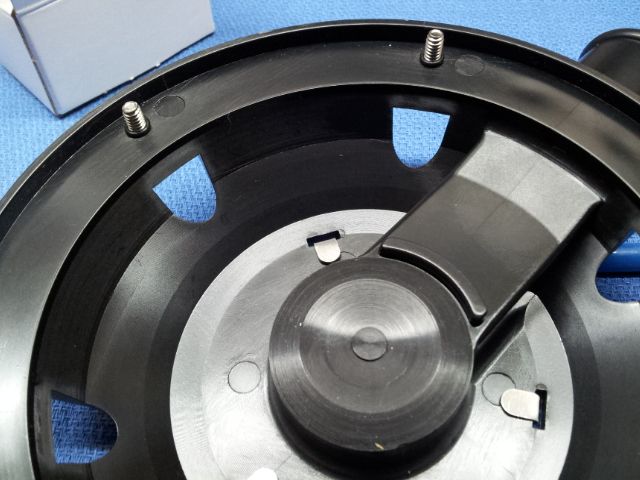

Argonaut Kraken Catalog Page

Be sure you click on the picture lower down on the page for more

information along with photos.

Phoenix and Argonaut Specialty Area

This is the area of the site where we discuss the Argonaut and

show a lot of behind the scenes stuff.

Can I use a DIN fitting?

Yes.....If you can find a DIN for a Conshelf XIV it will work. I have no

source for them nor any more information. I discourage DIN use on a double hose because it makes

the regulator stick out too far on most plate/backpack setups. This could make it difficult to position it

on your back for optimal breathing performance.

Yoke Pressure Rating?

4000 psi

Can I get on a waiting list?

NO...There is NO waiting list.......48 people ponied up their hard earned

cash during the Fundable crowd funding campaign to help me build the Argonaut. Those people have

either paid in full for an Argonaut Kraken or have paid to be on the list to buy one as soon as I'm

finished. So the first 48 are spoken for. Once everyone from the campaign has their Argonaut I will

put them in the website store for general sale.

If this happens it will be late in 2014 and there is NO

secret list and there will be NO secret notifications to anyone period. I think this is the most fair way to

do things so everyone has the same opportunity. Please watch the VDH Facebook page and the

Argonaut section of the website forum for any updates or new information on the Argonaut.

What color do they come in?

Any color as long as it's black. There is a color option on hoses. Black,

Yellow or Kraken Red. The red is a special color tint and may only be available for a short time.

Price?

Around $680.00

I will have one when the time comes and I really do love that red its just bad ass! This is just such an amazing project bringing the past alive for a new generation, who I might add has never had much if any contact with our history. I am just getting into the vintage thing so this to me is the right time to get involved!