- Messages

- 20,799

- Reaction score

- 15,524

- # of dives

- I'm a Fish!

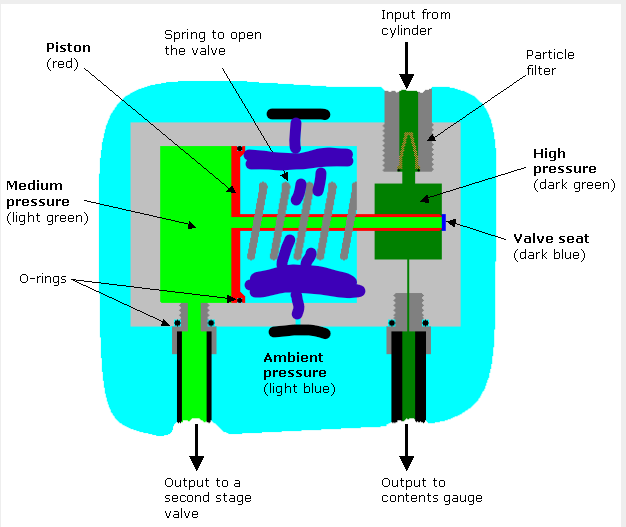

so to follow up on what @lowwall said, the environment seals would keep water out of the spring chambers. Where you see the gap in the body is where you would have the seals.

On the pistons, where the water is, is replaced by lubricant and a band is applied around the holes to keep the lubricant in. It is messy and expensive to service contrary to anything you hear from anyone who is sucking on the Atomic teat, it is nothing more than a bandaid and not a real solution.

Dark blue is the grease, black is the rubber band to keep the lube in. The risk here is that if the lube is not done properly, water can get into the chamber and cause worse problems to the piston than if you had left it exposed. This happens, not often, but it does happen and a new piston is close to $100.

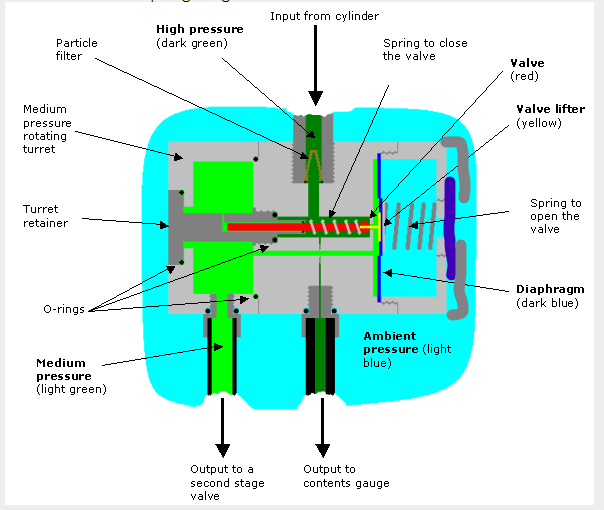

On the diaphragm, a second diaphragm is placed on top of the spring carrier

second diaphragm in dark blue, and the gray brackets are a metal cap that holds it in. Way better solution

Proponents of pistons will talk about how comparatively simple they are which is true, but more irritating to service since you have to shim them to set IP and it's generally irritating. They will also talk about how they can provide more gas than a diaphragm which is true for some though not really relevant since they all flow more gas than the valve is capable of supplying so does it really matter?

On the pistons, where the water is, is replaced by lubricant and a band is applied around the holes to keep the lubricant in. It is messy and expensive to service contrary to anything you hear from anyone who is sucking on the Atomic teat, it is nothing more than a bandaid and not a real solution.

Dark blue is the grease, black is the rubber band to keep the lube in. The risk here is that if the lube is not done properly, water can get into the chamber and cause worse problems to the piston than if you had left it exposed. This happens, not often, but it does happen and a new piston is close to $100.

On the diaphragm, a second diaphragm is placed on top of the spring carrier

second diaphragm in dark blue, and the gray brackets are a metal cap that holds it in. Way better solution

Proponents of pistons will talk about how comparatively simple they are which is true, but more irritating to service since you have to shim them to set IP and it's generally irritating. They will also talk about how they can provide more gas than a diaphragm which is true for some though not really relevant since they all flow more gas than the valve is capable of supplying so does it really matter?