captain

Contributor

Hello DeadlyRisk,

Someone here should know the correct o-ring sizes and hopefully will post them and make the rest of the following garbage moot.

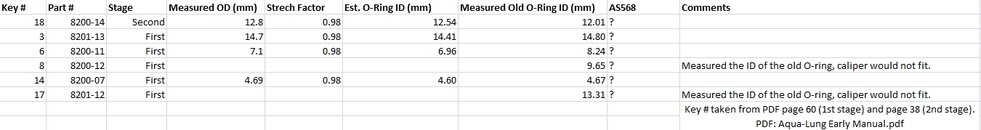

I probably do not need to tell you it is unwise to measure old o-rings in order to find the size needed. If memory serves me correctly, you should be able to determine the correct size by measuring the groove outside diameter (O.D.) Note that o-rings should be slightly stretched (1-5% with 2% being recommended) Therefore, after you measure the groove, multiply by 0.98 to find the inside diameter (I.D.) of the o-ring you need. Almost all regulator o-rings have a cross section (c.s.) of 1/16" therefore any o-ring with a 0 after the dash will have a c.s. of 1/16 and that make finding the correct seal pretty simple.

For instance, if you measure the small piston groove and get a dimension: 0.116 multiply by 0.98 to get the I.D. 0.11368 you need and find the closest match with a dash number of 0 at a site like What is AS568A? and you come up with a -006.

We Usual Suspects like to debate over the material, but I think most of us agree you cannot go wrong with Viton or EPDM. For hardness in low pressure applications 70-75 is fine, for high pressure go with 90.

......now where did I put that Parker manual?....

Couv

Usually there isn't enough difference in in size between an old O ring and the same size new O ring to confuse it with the next larger or smaller size new O ring.