Externet

Contributor

Perhaps this may be of good reference documentation for you to keep on file; manuals for some models are unobtanium:

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

Thank you Sir!Perhaps this may be of good reference documentation for you to keep on file; manuals for some models are unobtanium:

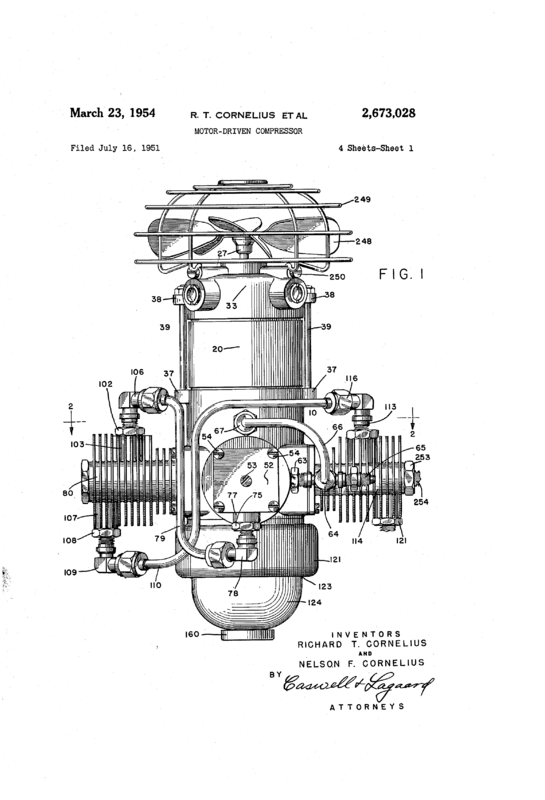

View attachment 639884

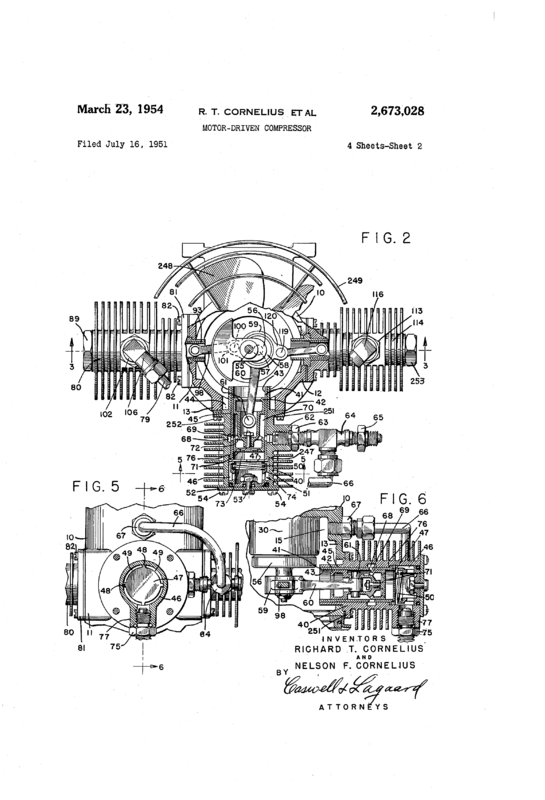

View attachment 639885

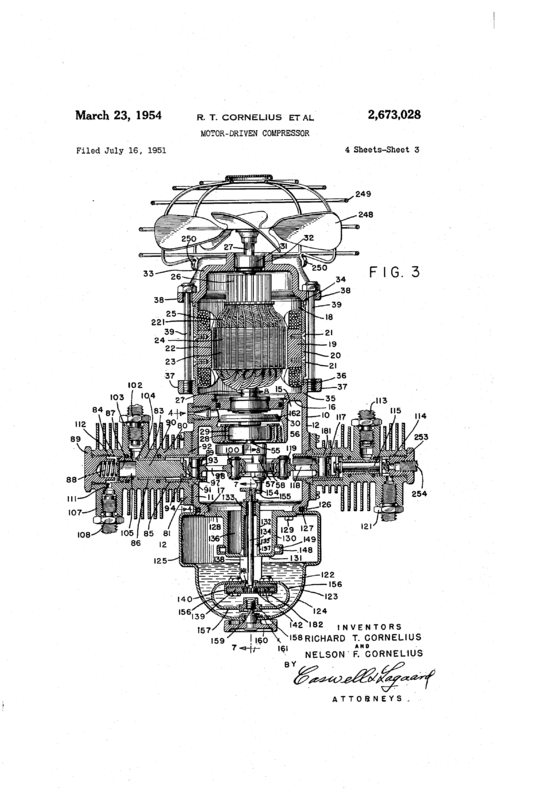

View attachment 639886

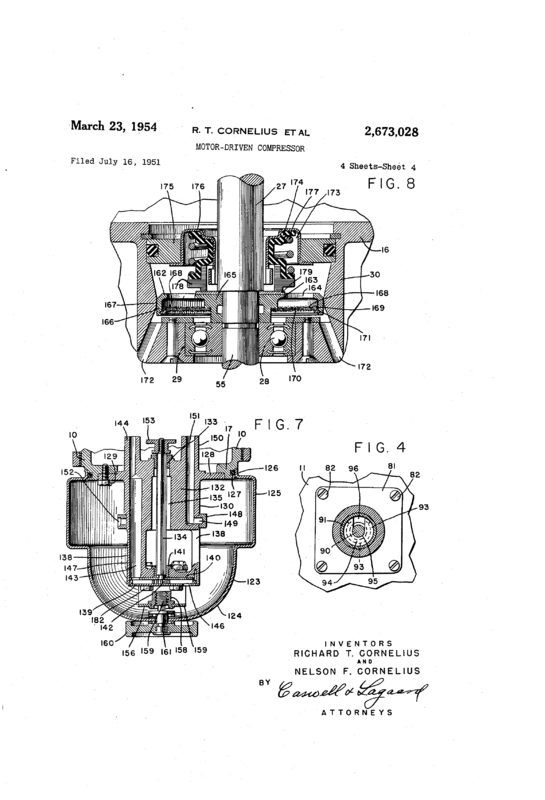

View attachment 639888

Thank you for the kind words. I have a pic of your compressor saved on my computer and believe it or not it’s the one that gave me the inspiration to build this one.Very nice job on your build. About ten years or so ago I had a Cornelius compressor but I don't remember what size motor I had on it. I later sold it to an air rifle enthusiast. It took forever to fill a 72 cu. ft tank so I bought a used Bauer Purus. Your build is so much better than the one I had. Again nice job.

I found a few photos of my old compressor and posted below

View attachment 640295

View attachment 640296

View attachment 640297

I have a copy as well. It calls for a 3450 rpm motor with a 4” pulley. The compressor gets a 2” pulley according to the article. This figures out to a final compressor rpm of 6900.Compressor should turn at 3400 to 3500 RPM

Unit will pump to 3000PSI> i have a copy of the original post in the magazine

Jim Shelden

316-992-0505