Luis,

Well that is quite a bit of work you did, but does raise some interesting points.

The original HSM table above was done over a decade ago if I recall using a previous version 2.? of the Cosa software, but not entirely sure. Either there was a mistake made in the original table which is unlikely as it was checked independently by two people, possibly the Cosa software at the time did not apply the enhancement factor correctly, or the vapor enhancement factor calculations have been revised since 2006. If you Google Greenspan water vapor enhancement factor you will see quite a few papers on updates to these uncertainty factors.

I did a quick cross check at 3000 psig, 80 F, and using the Sontagg vapor pressure equation without any uncertainty factor applied and came up with these pressure dew points (F).

Cosa 20.1

Michell 18.6

HumiCalc 18.6

Now applying the water vapor uncertainty factor (the Michell software won't allow this apparently because it only applies to air and their customers are using the software for other gases,....see FAQs) we have the following pressure dew points which match those in your table.

Cosa 15.6

Humicalc 13.7

Converting those to atmospheric dew point (F):

Cosa -61.8

Humicalc -63.0

Michell Humidity Calculator

Be Certain with Humidity Calculation Software | HumiCalc® | Humidity Conversion Software | By Thunder Scientific (demo version at bottom is free and does allow you apply under options the water vapor enhancement factor although they do not say which one)

Bottom line as mentioned in my previous post and only confirmed further by your updated findings is that once that 10% RH sector turns pink at any pressure it is time to switch out the cartridge for cold water diving.

If looking solely at the ability of the AC bed to remove volatile hydrocarbons from the air stream a cutoff of 20% RH is fine in Florida when the water temperature is 80 F.

We won't mention that the humidity strips in the Lawrence Factor after market cartridges change from blue to pink at 40% RH but they were never meant to be used for a solo purification tower rather the humidity indicator strips were meant to be used in a two or three filter 'train' where when the first cartridge turned pink you disposed of all the cartridges. If the front tower has an RH% of 40 the downstream towers would be in the 10% to 20% RH range. In a solo tower set up though you might approximate 10% to 20% RH when the first third of the strip had changed color.

For you in Maine or us in Canada we need the -65 F or colder atmospheric dew point to prevent first stage free flows. Work out the pressure dew point at 3000 psig and there is not much safety margin when the ocean water is - 2 C and one is breathing heavily or filling the dry suit or BCD to rapidly.

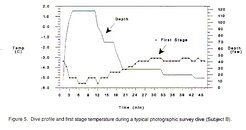

The figure attached is a thermocouple embedded in the outer brass covering of a Sherwood regulator while under the Antarctic ice. You can see the temperature drop with task loading at the start of the dive as drysuit and BCD are inflated and respiratory rates are higher all of which will drop the first stage temperature with air expansion from 3000 psig to intermediate pressure.

Taken from: Mastro, J and Pollock, N "Sherwood Maximus Regulator Temperature and

Performance During Antarctic Diving"

Proceedings of the fifteenth annual scientific diving symposium: Diving for Science.

Nahant, MA: American Academy of UnderWater Sciences, 1995:51-62.