Magnehelic Stand on Makerworld.

I don't have space on my workbench wall to mount my Dwyer 2003 Magnehelic at eye level and I've grown tired of crouching to get to eye level when the Magnehelic is standing vertically on my workbench. And staring down at it when it is laying horizontally on my workbench doesn't really work either. So I made an adjustable-tilt Magnehelic stand to position my Magnehelic in a good line of sight when I am setting 2nd stage cracking effort.

When I positioned my Magnehelic on a slant, I had to re-zero it. When on a slant, by comparing its reading to that of my DIY manometer, the Magnehelic maintains its accuracy to my eye (at least to the degree that I need). However, FYI, Dwyer's manuals say a Magnehelic should be mounted vertically.

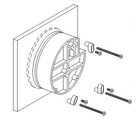

You will need the following hardware:

- One #10-24 hex head bolt (3" long) to serve as the hinge pin & an associated wing nut. Tightening the wing nut will lock the desired tilt into place.

- Three #6-32 machine screws (5/16" long) to mount the Magnehelic to the stand.

I don't have space on my workbench wall to mount my Dwyer 2003 Magnehelic at eye level and I've grown tired of crouching to get to eye level when the Magnehelic is standing vertically on my workbench. And staring down at it when it is laying horizontally on my workbench doesn't really work either. So I made an adjustable-tilt Magnehelic stand to position my Magnehelic in a good line of sight when I am setting 2nd stage cracking effort.

When I positioned my Magnehelic on a slant, I had to re-zero it. When on a slant, by comparing its reading to that of my DIY manometer, the Magnehelic maintains its accuracy to my eye (at least to the degree that I need). However, FYI, Dwyer's manuals say a Magnehelic should be mounted vertically.

You will need the following hardware:

- One #10-24 hex head bolt (3" long) to serve as the hinge pin & an associated wing nut. Tightening the wing nut will lock the desired tilt into place.

- Three #6-32 machine screws (5/16" long) to mount the Magnehelic to the stand.