richerso

Contributor

OK. You guys have found some things that I missed.... btw, I have been searching the research databases; but there is a lot of data to go through... Also, please be careful, let's not get general cylinder failures conflates with the topic that I am interested in..... Having said that, I do have one technical comment and one editorial comment here.

First, the editorial.... I love the "valve conversion" job the guy did from metric M25 to 3/4 NPSM... Classic.

Technical observation: If I can steal these two photos from the scubaengineer.com website,

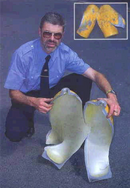

Image on the left shows what I would expect a properly heat treated cylinder to do. Note that the rupture initiates, in this case, at approximately the mid point location of the body of the cylinder; although the initiation point for this discussion is not relevant. The crack then propagates some distance before self arresting. Note that the cylinder has some outward facing plastic deformation as if it has suffered an aneurysm. The plastic deformation is very indicative of a ductile material. This is a classic ductile failure.

Image on the right shows what I would expect from a brittle failure. Note that there does not appear to be any plastic deformation in the cylinder (just as you don't see bent shards of broken glass if you ever dropped a piece of glass). Further there is more than one fracture line; and as should be clear, the fracture line did not self arrest. The fracture just continued to propagate until pieces of the cylinder were flying. Classic brittle failure.

I still need a material sample. Metallurgical and metallographic analysis will definitively show either a proper heat treatment or an improper heat treatment.

First, the editorial.... I love the "valve conversion" job the guy did from metric M25 to 3/4 NPSM... Classic.

Technical observation: If I can steal these two photos from the scubaengineer.com website,

Image on the left shows what I would expect a properly heat treated cylinder to do. Note that the rupture initiates, in this case, at approximately the mid point location of the body of the cylinder; although the initiation point for this discussion is not relevant. The crack then propagates some distance before self arresting. Note that the cylinder has some outward facing plastic deformation as if it has suffered an aneurysm. The plastic deformation is very indicative of a ductile material. This is a classic ductile failure.

Image on the right shows what I would expect from a brittle failure. Note that there does not appear to be any plastic deformation in the cylinder (just as you don't see bent shards of broken glass if you ever dropped a piece of glass). Further there is more than one fracture line; and as should be clear, the fracture line did not self arrest. The fracture just continued to propagate until pieces of the cylinder were flying. Classic brittle failure.

I still need a material sample. Metallurgical and metallographic analysis will definitively show either a proper heat treatment or an improper heat treatment.