Water bird

Registered

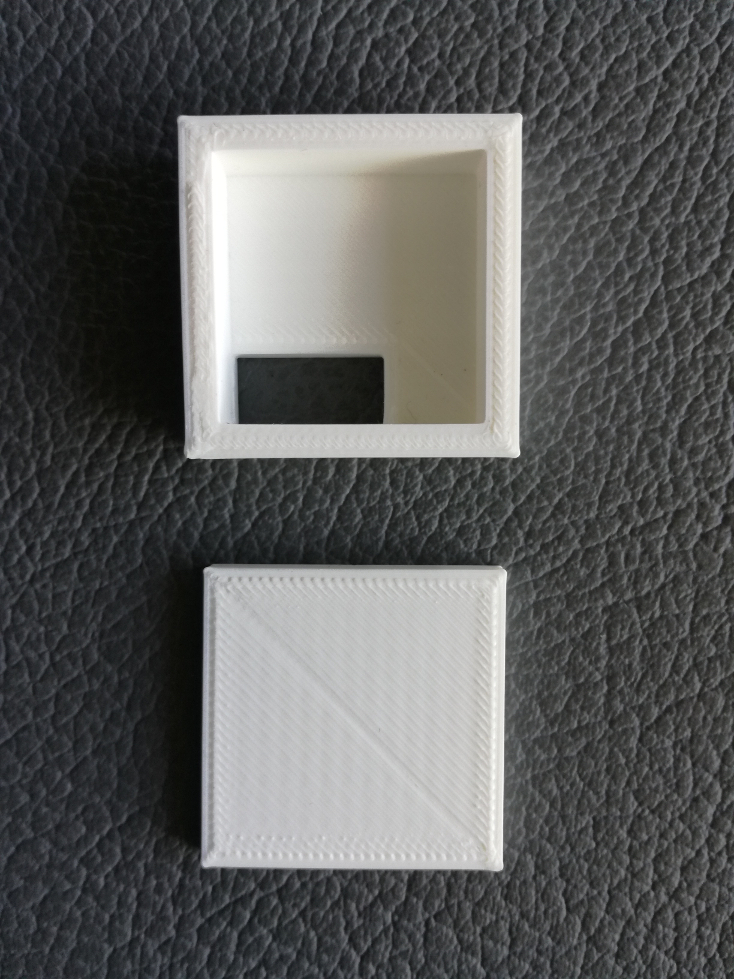

I would like to know the structure of this indicator light. If anyone has worked on a similar project, please let me know. Thank you!

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

diveino.hu

diveino.hu

Thank you for your response, Mobulai. This project is intended to be used on an ROV device at a depth of at least 100 meters. I’m not sure if 3D-printed components can withstand this pressure, considering the window has a diameter of only 4mm.Follow up questions:

What is this build for (if you feel like sharing)?

What construction methods are involved?(3d prints, off the shelf products…)

What level of waterproofing do you need? (What depth rating are you hoping for?)

Edit: if 3d prints are an option check this video out, @~8m

100m+ is probably very tough for a 3d printed hull, you are right.Thank you for your response, Mobulai. This project is intended to be used on an ROV device at a depth of at least 100 meters. I’m not sure if 3D-printed components can withstand this pressure, considering the window has a diameter of only 4mm.

Thank you for the information you provided, Mobulai. If I manage to design something better, you’ll be the first to know. I’ll carefully study the details you shared.Very cool indeed -- look forward to hear more about the progress of it

100m+ is probably very tough for a 3d printed hull, you are right.

In the video above they sealed FDM to 85m already, but the part I was referring to at minute 8 in the video shows only a 3d printed holder (that attaches from the inside) + a waterproof lens selead, with epoxy; that has much better chances of withstanding 100m+ I would say

the smaller your window (4mm is pretty small), the less you have to worry about pressure diffrential (and potential leaks)

One other method is tapering a thread for the window, and having an o-ring on the mating part (that has the window) in the style of diving lights

but that's much more complex to achive

Thank you, sir. This solution sounds great, and I will give it a try. Is Sikaflex the best brand for this?Simplest and more efficient way is to make lightpipe (https://si.farnell.com/c/optoelectronics-displays/light-pipes ) through lid

- to drill a hole , for window you want , cut threads in lid .

- cut polycarbonate screw with threads on wanted length .

- apply sealent/adhesive ( not really glue - should be elastic with positive displacement ) on threads like Sikaflex 291 , 291i

- screw in lid acrylic screw

attach wanted LED inside lid /housing

-----------------------------------------------------------

second option is to mold window in acryl plastic resin ( also with use of threads on lid for anchoring ) I use Stuers Epofix epoxy resin with a bit more resin because some shrinking )

Good day, thank you for your reply. I’m concerned that using Sikaflex might affect the light transmission of the window. Is my concern unnecessary?I have used Sikaflex polyurethane sealant but now use anything half the price for the same result

and as the sun comes up and the moon goes down, keep it in the fridge or freezer between uses

with the Aquaseal which would be better if you had some