Leto

Registered

Hi guys/girls,

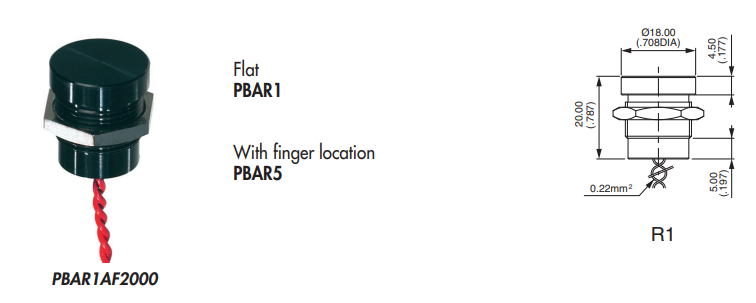

I got my hands on a nice acrylic lid (25mm / 1 inch thick) for a halcyon canister. Currently there is a regular mechanical switch installed which I want to replace with a more durable APEM piezo switch (IP69) (PBAR1AF2000). I hope you can help with a few questions.

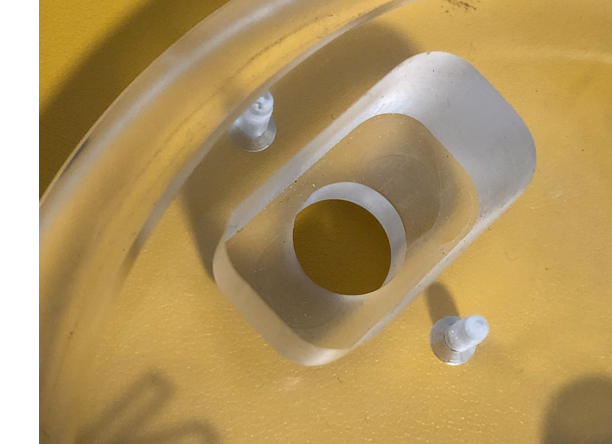

Can I simply increase the existing (12mm / ½ inch) hole to 16 mm, drop in the piezo switch with the oring and then tighten it using the supplied hex nut? The hole itself is not threaded, it’s just hex nut holding everything in place.

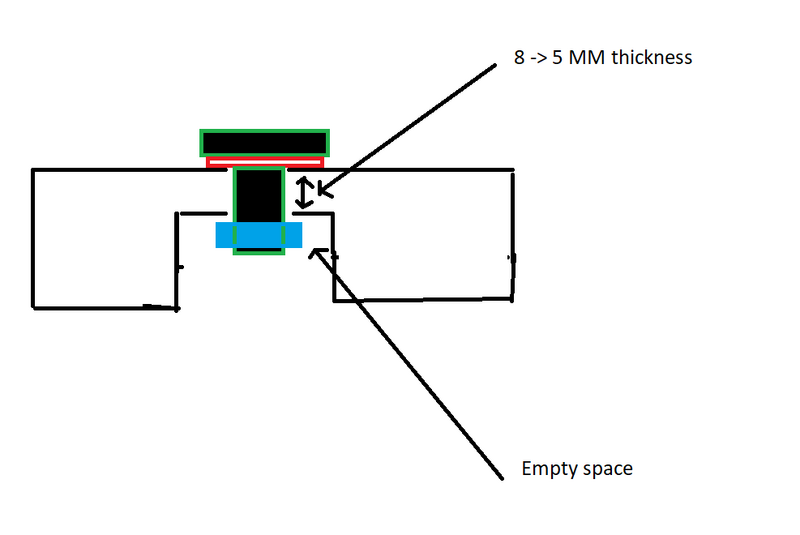

1. The threads on the piezo only allow for about 5mm of acrylic between the hex nut and the bottom of the switch / oring. While the mechanical switch this is more like 8 mm. Is it safe to reduce the acrylic to 5mm in this section in terms of depth rating? The lid / canister is rated to 300 ft but for me 150 ft is enough.

2. Do I need to use any epoxy to decrease chances of a leak or is the oring with the tightened hex nut (some Loctite maybe?) good enough?

3. The piezo is a lot smaller than the regular switch. Do I need to fill the empty rectangle space with some sort of epoxy to increase the strength of the lid?

Thanks for your time!

I got my hands on a nice acrylic lid (25mm / 1 inch thick) for a halcyon canister. Currently there is a regular mechanical switch installed which I want to replace with a more durable APEM piezo switch (IP69) (PBAR1AF2000). I hope you can help with a few questions.

Can I simply increase the existing (12mm / ½ inch) hole to 16 mm, drop in the piezo switch with the oring and then tighten it using the supplied hex nut? The hole itself is not threaded, it’s just hex nut holding everything in place.

1. The threads on the piezo only allow for about 5mm of acrylic between the hex nut and the bottom of the switch / oring. While the mechanical switch this is more like 8 mm. Is it safe to reduce the acrylic to 5mm in this section in terms of depth rating? The lid / canister is rated to 300 ft but for me 150 ft is enough.

2. Do I need to use any epoxy to decrease chances of a leak or is the oring with the tightened hex nut (some Loctite maybe?) good enough?

3. The piezo is a lot smaller than the regular switch. Do I need to fill the empty rectangle space with some sort of epoxy to increase the strength of the lid?

Thanks for your time!