Copy/Paste from an old Sherwood Service Bulletin:

Certainly one of the strongest of SHERWOOD's patented features is the Positive Air Purge (Dry Air Bleed) System, which keeps the interior of the first stage completely clean, and dry. The system is very rugged but does need a bit of forethought on the repair technician's part to insure that it keeps working. When we travel to various Dive Stores world wide, we try to audit a few regulators in each store to see how they are standing up. We are still finding from time to time, entire groups of SHERWOOD regulators with no air coming from the One Way Bleed Valve when the air is turned on. Inevitably, when we open these regulators, we find the Piston coated with a layer of grease which clogs the small stainless steel flow element located in the large piston face. This grease usually gets there due to improper servicing techniques, such as the following:

1. The entire piston is sprayed with silicone grease before installation to "prevent corrosion".

2. The Piston 0-Rings and Cap are heavily over lubricated with silicone grease which then squashes down and covers the end of the piston when the piston is inserted into the cap.

3. The Piston is "cleaned" in a dirty, over used cleaning bath, which coats the piston with grease as it is removed from the bath.

4. The Piston is handled with very greasy finger tips during servicing, which covers the Flow Element in the Piston.

An attempt can be made to clean the grease from the flow element. Use a very warm, and fresh batch of cleaning solution in an ultra sonic cleaner. Keep the piston in the bath for a fair length of time. Remove the piston from the fluid, and blow it dry thoroughly with clean dry compressed air. Pay particular attention to drying both sides of the flow control element. Install the piston into the regulator using techniques described in the appropriate SHERWOOD Service Manual, and check the flow rate as per instructions in the manual. If the flow rate is not quite up to minimum level, then a repeated attempt at cleaning should be made. If the flow through the piston element has been obstructed due to improper servicing techniques, the replacement of the piston is not covered by warranty. Corrosion in the spring chamber, or the back side of the piston face are seldom if ever, the cause of diminished flow through the One Way Bleed Valve. Rather, corrosion is usually a symptom that the flow element has been clogged, and the system has been made inoperative.

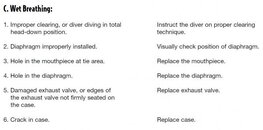

Troubleshooting tips from a Sherwood repair manual regarding wet breathing have no mention of the One Way Bleed Valves. Also, note their repeated use of One Way Bleed Valve above.

Certainly one of the strongest of SHERWOOD's patented features is the Positive Air Purge (Dry Air Bleed) System, which keeps the interior of the first stage completely clean, and dry. The system is very rugged but does need a bit of forethought on the repair technician's part to insure that it keeps working. When we travel to various Dive Stores world wide, we try to audit a few regulators in each store to see how they are standing up. We are still finding from time to time, entire groups of SHERWOOD regulators with no air coming from the One Way Bleed Valve when the air is turned on. Inevitably, when we open these regulators, we find the Piston coated with a layer of grease which clogs the small stainless steel flow element located in the large piston face. This grease usually gets there due to improper servicing techniques, such as the following:

1. The entire piston is sprayed with silicone grease before installation to "prevent corrosion".

2. The Piston 0-Rings and Cap are heavily over lubricated with silicone grease which then squashes down and covers the end of the piston when the piston is inserted into the cap.

3. The Piston is "cleaned" in a dirty, over used cleaning bath, which coats the piston with grease as it is removed from the bath.

4. The Piston is handled with very greasy finger tips during servicing, which covers the Flow Element in the Piston.

An attempt can be made to clean the grease from the flow element. Use a very warm, and fresh batch of cleaning solution in an ultra sonic cleaner. Keep the piston in the bath for a fair length of time. Remove the piston from the fluid, and blow it dry thoroughly with clean dry compressed air. Pay particular attention to drying both sides of the flow control element. Install the piston into the regulator using techniques described in the appropriate SHERWOOD Service Manual, and check the flow rate as per instructions in the manual. If the flow rate is not quite up to minimum level, then a repeated attempt at cleaning should be made. If the flow through the piston element has been obstructed due to improper servicing techniques, the replacement of the piston is not covered by warranty. Corrosion in the spring chamber, or the back side of the piston face are seldom if ever, the cause of diminished flow through the One Way Bleed Valve. Rather, corrosion is usually a symptom that the flow element has been clogged, and the system has been made inoperative.

Troubleshooting tips from a Sherwood repair manual regarding wet breathing have no mention of the One Way Bleed Valves. Also, note their repeated use of One Way Bleed Valve above.