Google this and you will get a XLS file. I dont know why I cant attached a short link.

scubaengineer filter life calculator

Bauer also has their own XLS version which you can adjust the molecular sieve quantity and use it for different compressor brands.

I played with Bauer P21, P41 and P81 filter system a great deal. But have abandoned P21 size, too small.

Using 39C as final temperature to compensate filter life, I never go wrong. I am at 30C almost all year round. I use extra forced cooling too.

In fact since I am not doing ice diving, I can extend a bit more life because air dryness only need to be at -48C dewpoint and not -55C.

-48C is only to make sure the activated carbon and hopcalite to works as it should.

Example , my Mariner 200 with P41 has used-up 12 of 675 grams MS filter cartridge ( with hopcalite P/N 67224 ) so far never off the mark and never any MS get tanned color with 39C as final temperature. I measure final water separator temperature skin temperature in real time with a thermocouple. Its between 36C to 40C depending on how long I run in one go. Its near 600 hours running already. I even measure the weight of my expired filter cartridge P41 down to 2 grams accuracy. Its not all water moisture adsorbed, some other "bad stuff" too, based on total weight between new and expired cartridge. Deduct the potential water weight & weight as new, the balance is whatever bad stuff an oil based compressor is producing

.

By monitoring water condensate color and oil content, you can also tell your piston rings conditions or how much piston blow-by is leaking. More oil traces in water condensate is another sign of excessive piston blow-by. Oil can tan MS too you know.

By weighing my filter cartridge expired weight, I can confirm increase weight could be the extra oil being adsorb. I actually look for anomaly or out of pattern condition and this can be done, because since new I been taking all these notes for my compressor. Sooner or later piston rings will be worn out.

Here is the last few cartridges I measured :

08. P/N 67224, CO remover. 17 Feb 2011. Weight 1402 grams. 9 April 2011, 1630 gram. 49 hours.

09. P/N 67224, CO remover. 9 April 2011. Weight 1431. 27 May 2011, 1659 gram, 49 hours.

10. P/N 67224, CO remover. 27 May 2011. Weight 1418. 18 July 2011, 1652 gram, 49 hours.

11. P/N 67224 CO remover. 18 july 2011. Weight 1392. 10 Sept 2011, 1635 gram, 49 hours.

12. P/N 67224 CO remover. Sep 10 2011. Weight 1387. 31 Oct 2011, 1630 gram, 49 hours.

If you see the extra weight after expiry, it is between 228 grams to 243 grams. Of course there is a bit deviation on final temperature depending how long the compressor run in one go, hence more water in the air and ambient temperature may vary 29 to 33C but I use 39C as reference for final temperature. The cartridge I use is 675 grams of MS. In theory I probably load it up to 21-22% of water or approx 141 to 148 grams. So there is approx 100 grams of unknown being adsorbed....

and some of those are oil for sure.

If one day I start getting expired weight increase to say 260 grams consistently under the same working condition, something is wrong with my compressor. Bauer 41 filter cartridge is aluminum and not easy to cut open. So far I have cut number 4 as per photo I showed you and will start cutting open again when I see 250+ grams consistently as extra weight and surely watch out for the water condensate color and oil level.

If you want manual calculation, this is how to calculate filter life , based on PMV set at 150 BAR and tank fillling to 207 BAR.

Volume of air which can be processed: ( this is available in Bauer user manual ).

Va [m3] = 0,2 x mMS [g] / (X [g/m3] / p [bar]) = 0,2 x p [bar] x mMS [g] / X [g/m3]

Va[m3] is cubic meters of air

0.2 is the 20% water adsorbing capability of the molecular sieve. Yes, not 23% because there must be a buffer for dry air.

mMs[g] is mass of Molecular Sieve in grams

p[bar] is the filling pressure of the tank in BAR

X[g/m3] is the water content of air per cubic meter at final temperature

/ means divided by

x means multiply by

Like this based on a Bauer P21 filter with 68 grams MS :

0.2 x 200 BAR x 68 grams divided by 51.21 ( assumed 40C final temperature ) is = 53 M3 liters of air use .

53 M3 is 53,000 liters is equal to 4.4 hours of a 200 liters per minute compressor run at 200 BAR.

Water content in air based on temperature at 100% humidity ( yes in a compressed air situation it is a 100% humidty ).

See photo attachment

Happy air making.....

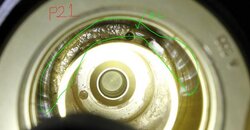

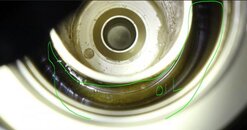

yuccckkkk !!!!

yuccckkkk !!!! Abused compressor v1.jpg26.3 KB · Views: 184

Abused compressor v1.jpg26.3 KB · Views: 184 Abused compressor v2.jpg25.3 KB · Views: 196

Abused compressor v2.jpg25.3 KB · Views: 196 Abused compressor v3 - oil soaked molecular sieve.jpg28.5 KB · Views: 224

Abused compressor v3 - oil soaked molecular sieve.jpg28.5 KB · Views: 224 Abused compressor v4 - oil soaked activated carbon.jpg29.7 KB · Views: 214

Abused compressor v4 - oil soaked activated carbon.jpg29.7 KB · Views: 214 Abused compressor v5 - oily pads.jpg28.7 KB · Views: 202

Abused compressor v5 - oily pads.jpg28.7 KB · Views: 202 Proper life limit of molecular sieve and activated carbon from an expired catridge.jpg30.8 KB · Views: 219

Proper life limit of molecular sieve and activated carbon from an expired catridge.jpg30.8 KB · Views: 219 Proper life limit of filter cartridge - filter pad of P41.jpg25.3 KB · Views: 215

Proper life limit of filter cartridge - filter pad of P41.jpg25.3 KB · Views: 215