Another vote for always knowing your PO2 regardless of the unit. Good points about the gas switching protocol as well. This is why I've never been comfortable even diving the Dolphin w/o monitoring my PO2.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fatality at WKP

- Thread starter Belmont

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

With the RB80 you are supposed to know the drive gas is correct and your personal ppO2 drop to avoid relying on electronics. Flashing bells and whistles are conciously avoided on the Rb80. I think the current 6/11 issue of Alert Diver has an article on CCR warning gizmos which describes how they are no solution either.

There are extremes in RB designs -

1. Fully automatic no manual control vs full manual control.

2. PPO2 Alarms/Bells/Vibration vs No Alarms

3. PPO2 monitoring vs no PPO2 monitoring.

RB80 has adopted Manual Control, No PPO2 Monitor and thus no PPO2 alarms. My RB also has Manual Control, but full knowledge of PPO2, but I have no alarms other than green/yellow/red leds on my HUD and color coded readout on my Shearwater display.

The responsibility is mine to monitor my PPO2 and adjust accordingly. I do not have to manually calculate my PPO2 based on depth, SAC, workload, and onboard/offboard gas mix.

- Messages

- 14,180

- Reaction score

- 11,412

- Location

- Port Orchard, Washington State

- # of dives

- 1000 - 2499

There are extremes in RB designs -

1. Fully automatic no manual control vs full manual control.

2. PPO2 Alarms/Bells/Vibration vs No Alarms

3. PPO2 monitoring vs no PPO2 monitoring.

RB80 has adopted Manual Control, No PPO2 Monitor and thus no PPO2 alarms. My RB also has Manual Control, but full knowledge of PPO2, but I have no alarms other than green/yellow/red leds on my HUD and color coded readout on my Shearwater display.

The responsibility is mine to monitor my PPO2 and adjust accordingly. I do not have to manually calculate my PPO2 based on depth, SAC, workload, and onboard/offboard gas mix.

I'm not saying I agree with the RB80 design. It is what it is right now. Which is full manual no electronics of any kind so there's no electronics to fail or give you inaccurate info. ppO2 is "known" by other means which obviously failed in this case.

I would be surprised if the support divers took the deco bottles down to drop them. Maybe they do, but I think they come to pick them UP at the end of the dive, but the diver takes them down with him. I'd be really, really uneasy, myself, trusting that a team behind me was putting the gas I needed for safety in place. What if someone had ear problems or for some other reason couldn't complete the dive?

Rick, I think your takeaway is an excellent one. I was taught in C2 that switches on and off bottom stages did not have to be watched, because after all, it was all the same gas. So, in that case, the deco bottle drop DOES need to be confirmed. I was not taught that, and it's a good addition to procedures.

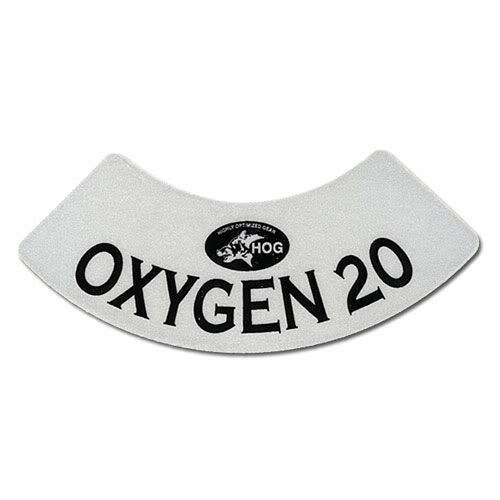

I have always considered that anytime I change what I am breathing it is a gas switch. That goes for staging as well as deco. In fact that is why I had my MOD decals made for the neck of my stage and deco bottles. It is unlikely that I would not catch a mistake made in procedure (not doing switch correct) when I look at the bottle and see the MOD staring me in the face

- Messages

- 1,410

- Reaction score

- 2

- # of dives

We watched switches as a team. Not so much for the MOD (although we did look) but because regs get junk in them, people cough at exactly the wrong moment, free flows happen... Basically if something can go wrong it will go wrong at a switch.

Exactly. Although there is an argument for always doing it the same way because once you get out of class and use more than bottom gas and O2,something can and will happen eventually.

- Messages

- 14,180

- Reaction score

- 11,412

- Location

- Port Orchard, Washington State

- # of dives

- 1000 - 2499

Exactly. Although there is an argument for always doing it the same way because once you get out of class and use more than bottom gas and O2,something can and will happen eventually.

Going forward I think we will make a concerted effort to be more sequential and less simultaneous. We have occasionally done some things (deploying the reg) as a group then shown each other and verified together. Breaking this down into more sequential steps will take <1min so I think we're just a bit (not completely) lazy for no real benefit.

I'm not saying I agree with the RB80 design. It is what it is right now. Which is full manual no electronics of any kind so there's no electronics to fail or give you inaccurate info. ppO2 is "known" by other means which obviously failed in this case.

The KISS GEM comes with a ppO2 display, but I was told at DEMA when I was first looking at the unit that most divers only use if during training and for a few dives after. While in my short time diving my GEM I can see that the ppO2 matches up exactly what it should it's nice to have that verification there to look at. If a time ever comes that the ppO2 is vastly different than what I think it should be a quick check of the bottle plumbed into it should verify whether it's an electronics failure or a diver failure. I'm keeping my sensor and electronics, if for nothing else than an additional checkpoint.

In formulating procedures and protocols, they have to make sense; they have to have a valid reason. If you create a protocol that makes downstream protocols obsolete, then an insistence that you adhere to the obsolete protocol "because you might screw up the new one" is the quickest way to breed complacency in the entire system, and a fast track to a failure of *all* the protocols.

Rick

Rick

In formulating procedures and protocols, they have to make sense; they have to have a valid reason. If you create a protocol that makes downstream protocols obsolete, then an insistence that you adhere to the obsolete protocol "because you might screw up the new one" is the quickest way to breed complacency in the entire system, and a fast track to a failure of *all* the protocols.

Rick

Keeping the O2 sensor is not a protocol for a possible screw up. It's a sanity check. Just like my dive computer is a sanity check. I don't fly my computer on decompression dives. I plan my dives and dive my plans. But I also use a dive computer as verification that all is well. Same goes for SPGs. When I look at SPGs I'm only verifying the gas volume left, not checking to see what it is. Applying that same thought process, I should get rid of my SPGs because they breed complacency.

Similar threads

- Replies

- 0

- Views

- 388

- Replies

- 0

- Views

- 522

- Replies

- 0

- Views

- 642

- Replies

- 0

- Views

- 627

- Replies

- 0

- Views

- 898