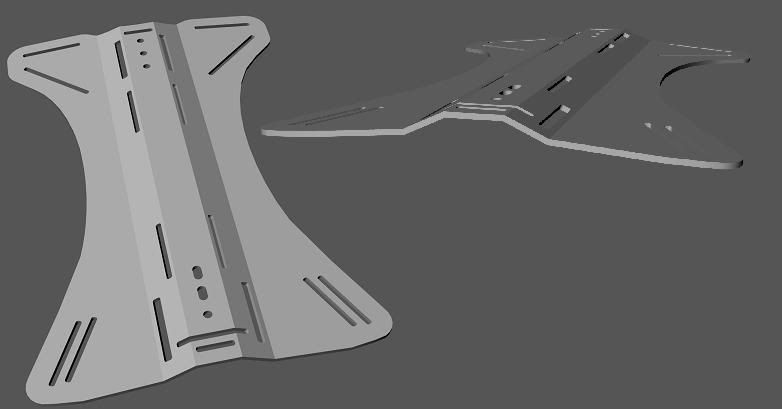

I hadn't thought about only moving the diagonal slots but I really like that idea. The only problem I can see with this is that the harness will then cover the cam band slots. Make the cam band slots thick enough to pass both the harness webbing and the cam band through it and that should move the harness webbing completely out of the way. It also will no longer move a single tank farther away from your body.

Hey Tobin, I hope your still listening ;-)

Another thing to consider would be to bend the center channel inward like on the mark meadows plate so that it acts as a built in STA. Then you don't even need an integrated soft STA like some systems use. If you do it right it should still work fine with doubles or an STA if you decide to go that way.

~Jess

Hey Tobin, I hope your still listening ;-)

Another thing to consider would be to bend the center channel inward like on the mark meadows plate so that it acts as a built in STA. Then you don't even need an integrated soft STA like some systems use. If you do it right it should still work fine with doubles or an STA if you decide to go that way.

~Jess