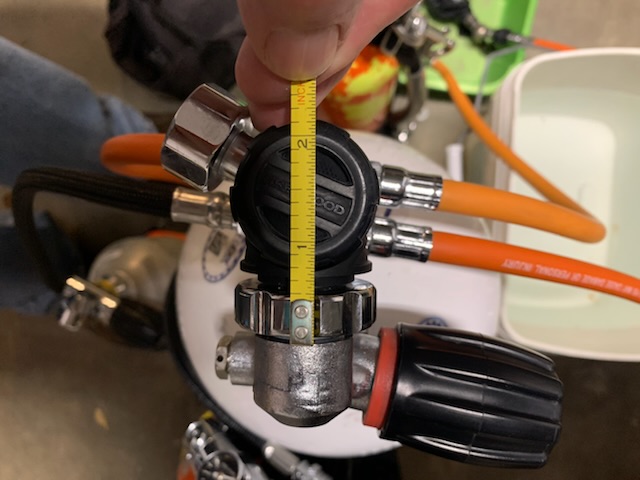

But the OP's question is how much further out is the DIN reg into a yoke adapter?Distance is less than 1/4 inch difference.

Aqualung Core Supreme reg in both DIN and Yoke:

View attachment 776473View attachment 776474

The face of the yoke reg seats against the tank o-ring. The DIN reg screws into the tank valve for all but 3 threads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question DIN Size

- Thread starter DrMattWill

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

gmerick

Contributor

Din adapter -- the end of the DIN reg seats against the inside of the adapter. The adapter ridge seats in the same manner as the yoke reg. This means the entire length of the DIN threads is the additional distance toward your head.

Belzelbub

Contributor

It's mainly a statement about the number of o-rings making the seal. Each o-ring is a potential point of failure, so more is not an improvement, unless they happen to be positioned such that they can back the others up." A DIN reg on a yoke tank with the adapter is the most trouble-prone connection you can have. "

Is this factually true or just an opinion? I never thought of this before.

With a yoke reg on a yoke valve, there is one o-ring making the seal. It lives on that tank, so conditions may be rougher.

With a DIN reg on a DIN valve, there is still one o-ring, but it lives with the reg. (My tanks are stored in my garage, but my regs are stored indoors, humidity controlled)

With a yoke reg on a pro-valve, you've got two o-rings in the equation. One DIN sized o-ring on the inside of the insert, and a yoke sized o-ring on the outside.

With a DIN reg with a yoke adapter on a yoke valve, you've got two o-rings in the equation again, but now the setup is bulkier by a bit.

With a DIN reg, yoke adapter, on a pro-valve, you've got 3. Only reason to do this is if you don't have the right Allen wrench, or the insert is stuck.

I bought a DIN reg before converting some of my tanks over to DIN. I used the adapter for those and it worked out OK. Not ideal for the reasons mentioned above. You'll often hear mentioned that the big problem is hitting your head on the reg. I never had this problem, but I suspect configuration of the reg (Straight line vs. L) as well as positioning of the tank will determine if there is contact or not.

If you're building out the systems from 'scratch', add about 6" to your primary and secondary hose and when you need to use the DIN+adapter, mount it backwards (1st stage body facing towards the rear).Without getting into a DIN vs. Yoke, can people let me know about the size comparisons?

Length of DIN?

Length of DIN+Adapter?

Length of Yoke?

I am primarily interested in comparing the size. Since I am leaning towards a DIN, I am concerned about the total size of the DIN+Adapter and it might hit me in the head.

That way you have way less protruding towards the back of your head than either a DIN or yoke first stage.

Another alternative (what I do) is to mount the tank at an angle (1st stage body is not directly in line with your head)

I have both yoke and DIN fittings for by reg, I just swop them over as required. The cost of the DIN fitting was the same as a converter.

L13

Contributor

That configuration does actually have 1 more threaded connection and 1 more o-ring. This will result in a slight increase in risk." A DIN reg on a yoke tank with the adapter is the most trouble-prone connection you can have. "

Is this factually true or just an opinion? I never thought of this before.

I am not a fan of measuring risk by failure point count, since not all failure points are equal. In this case, the risk increase is smaller than the risk increase from DIN to yoke, and is likely small compared to many other decisions you may make. On the other hand, on a particular dive it might be the particular risk increase that actually ended up making a difference in the outcome. Only you can decide if that risk increase is worth the convenience for you in your particular dive situation.

Tess verbose answer,

yoke

DIN

DIN and common adaptor

DIN and common adaptor

all 3 sherwood first stage

yoke

DIN

all 3 sherwood first stage

Bingo! This is exactly what I do. Makes for more a secure, lower profile and trouble free connection. Takes one minute to change over. I'm actually doing this in a few weeks. I have an Apeks ATX200 in DIN configuration for diving here in the PAC NW, but when in Bonaire for 10 days coming up soon, I'll switch the configuration to Yolk... I still bring my adaptor because inevitably someone will need it..I have both yoke and DIN fittings for by reg, I just swop them over as required. The cost of the DIN fitting was the same as a converter.