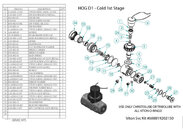

Hi all,

I own a bunch of HOG D1 regs and have done about 20 services on them (total) over the years.

I typically get about 1-2 years of use (100 dives) out of them, before they start showing the same issue, leaking out the body on the HP side.

Never had an IP issue (one did rise about 3psi and lock up after 10 seconds), but they all bubble out.

Since it’s that weird time of year for me where things are starting to ice over (too thick to safely dive, too thin to walk out and cut a hole), starting to do some more service work in the down time.

Curious if there might be something I’m not doing as correct when cleaning or assembling them at service?

Hints/ideas?

Thanks!!

_R

I own a bunch of HOG D1 regs and have done about 20 services on them (total) over the years.

I typically get about 1-2 years of use (100 dives) out of them, before they start showing the same issue, leaking out the body on the HP side.

Never had an IP issue (one did rise about 3psi and lock up after 10 seconds), but they all bubble out.

Since it’s that weird time of year for me where things are starting to ice over (too thick to safely dive, too thin to walk out and cut a hole), starting to do some more service work in the down time.

Curious if there might be something I’m not doing as correct when cleaning or assembling them at service?

Hints/ideas?

Thanks!!

_R