This info is highly likely somewhere here or linked to here... I am just not finding it...:

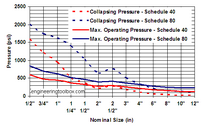

If not used in tension (internal pressure), as they are rated for, but in compression (submersion) how deep can run off the mill schedule 40 PVC pipe and fitting made "containers" (and schedule 80?) be taken before they spring a leak or worse?

... does that change as the diameter gets bigger (likely for burst, not sure about leak). Mostly interested in diameters 2, 3 and maybe 4 inches.

To simplify things, lets say I just make a buoancy chamber. No removable lids etc. just a length of pipe with two on the outside overlapping endcaps properly glued on. Up to what depth should it survive - repeatedly...? How do you figure?

If not used in tension (internal pressure), as they are rated for, but in compression (submersion) how deep can run off the mill schedule 40 PVC pipe and fitting made "containers" (and schedule 80?) be taken before they spring a leak or worse?

... does that change as the diameter gets bigger (likely for burst, not sure about leak). Mostly interested in diameters 2, 3 and maybe 4 inches.

To simplify things, lets say I just make a buoancy chamber. No removable lids etc. just a length of pipe with two on the outside overlapping endcaps properly glued on. Up to what depth should it survive - repeatedly...? How do you figure?