The D420 CAD video shows the use of the Flow Vane Face Spanner PN 43.420.012 in screwing the valve assembly into the precise position necessary to complete service.

The Venturi sleeve (flow vane) needs to be in the correct position, and the flow vane ring needs to be correctly aligned to add the washer and Pre-dive switch. So of course I ordered one!

It comes in, and whaaaat!?? Ninety dollars? Well, I want to do this right. So...okay.

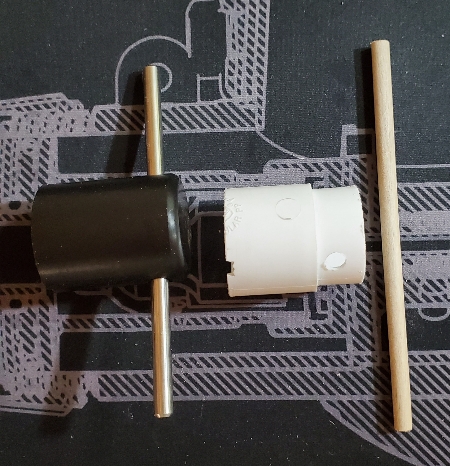

So I get home, and this is what my $90 bought.

You gotta be kidding me, right?

In the interest of DIY'ers everywhere, here is an $8 alternative.

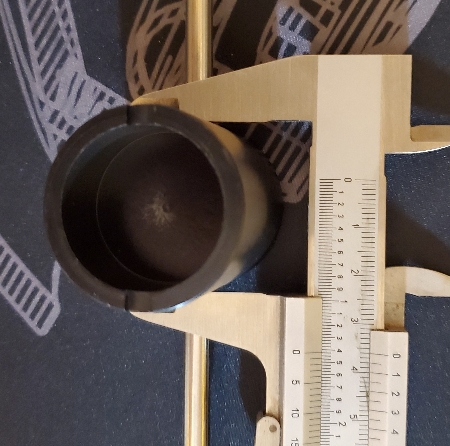

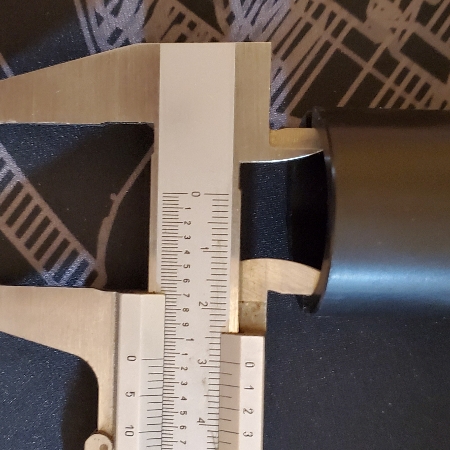

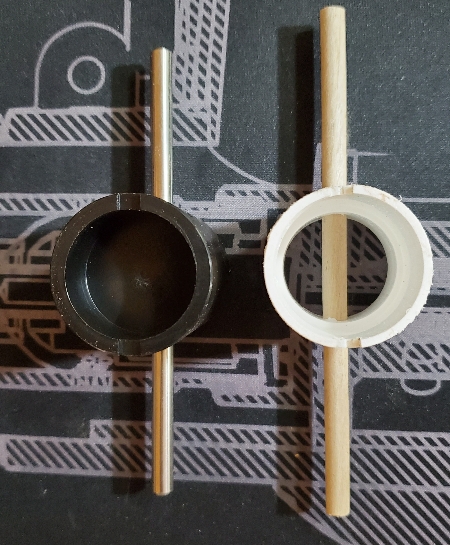

To start with, the tool is basically a cylinder with two notches, with a handle that tells you you've aligned the flow vane ring properly. The cylinder is 29mm ID and 36mm OD. The handle is aligned with two 5mm notches. That's it.

But when you go to the hardware store, you discover that it is particularly difficult to find a cylinder of those dimensions. Here's a cheap compromise.

A sink drain is too narrow, but the transition to the sink attachment point is just right! A copper 1 1/4" coupling is similarly sized. Both are $5-6. If you don't have a 1/4" dowel lying about, that's not very expensive.

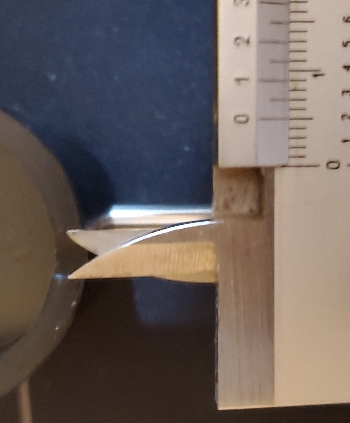

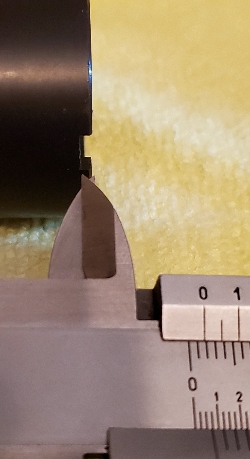

For the plastic version, start by trimming off the sink connection, and carve two notches 5mm x 1.5mm diametrically opposite each other.

Drill two 1/4" holes exactly in line with the notches (that part can be a little tricky - start with a tiny hole for centering).

Cut off the excess drain. Thread in the dowel, and boom! You're done.

The Venturi sleeve (flow vane) needs to be in the correct position, and the flow vane ring needs to be correctly aligned to add the washer and Pre-dive switch. So of course I ordered one!

It comes in, and whaaaat!?? Ninety dollars? Well, I want to do this right. So...okay.

So I get home, and this is what my $90 bought.

You gotta be kidding me, right?

In the interest of DIY'ers everywhere, here is an $8 alternative.

To start with, the tool is basically a cylinder with two notches, with a handle that tells you you've aligned the flow vane ring properly. The cylinder is 29mm ID and 36mm OD. The handle is aligned with two 5mm notches. That's it.

But when you go to the hardware store, you discover that it is particularly difficult to find a cylinder of those dimensions. Here's a cheap compromise.

A sink drain is too narrow, but the transition to the sink attachment point is just right! A copper 1 1/4" coupling is similarly sized. Both are $5-6. If you don't have a 1/4" dowel lying about, that's not very expensive.

For the plastic version, start by trimming off the sink connection, and carve two notches 5mm x 1.5mm diametrically opposite each other.

Drill two 1/4" holes exactly in line with the notches (that part can be a little tricky - start with a tiny hole for centering).

Cut off the excess drain. Thread in the dowel, and boom! You're done.