I think it comes down to the alloy. The tanks on that link look to be 3AL which is perfectly fine. Older tanks with an alloy of 6498 used to get the 3AL stamp and could be filled but now no one is filling them because of the alloy its made of. Id be willing to bet your "beat up" tanks have that or another similar alloy. Do you know if they were 3AL or not?

"3AL" has nothing to do, per se, with the alloy. That is the DOT standard under which they're certified. Older 6351 tanks were not originally certified under DOT3 - they were usually special permit tanks, but at some point DOT converted those special permit tanks (some, maybe all - not gonna spend a ton of time researching the conversion) over to DOT3 classification. \

I think you are referring to use of 6351-T6 alloy. It had a higher lead content to the alloy mix than 6061-T6 alloy which Catalina always used - or even all Luxfer Al bottles manufactured since mid-1988.

Some of the 6351 bottles exhibited a tendency to crack/fracture in the shoulder/neck/thread area of bottles caused solely by the stress of being filled to pressure over time. This is called "Sustained Load (Stress) Cracking" or usually abbreviated SLC. That kind of cracking is usually considered a bad thing.

Yours is an intelligent question though - the concern IS in the alloy. Or should be. Not on the age. The shop in question, in my opinion, couldn't tell its theoretical ass from a hole in the top of a scuba bottle. Even when confronted by legitimate, authoritative information and documentation. This is because I don't believe they could even spell 6-3-5-1 or S-L-C, much less tell you who made them 6351 scuba bottles (Luxfer, Walter Kidde, Cliff Impact, mainly), when they were made, and what the concern with 6351 bottles is. They just say 20 years is too old to fill. Big signs posted at their facility (or were, back when I didn't know better to avoid them a couple of years ago) say as much. Then out of the other side of their mouth will try to sell 24-25 year old bottles on scooba bored.

Even the old 6351 bottles can still be used and filled to the owner's heart's content, legally, ethincally, and safely, provided they pass eddy-current testing at the 5 year hydro mark (DOT regs) and annual VIP of those tanks should also include the eddy-current test (not DOT mandated).

I have a couple of old Luxfer 6351 bottles I still use but not in a pressurized capacity because I don't want the hassle of the more expensive, I mean extensive, annual testing. One of my 6351 bottles is prettier than any new bottle on an LDS' showroom floor - that one I use for holding valves when torquing the packing nut or the over-pressure plug (burst disk) when I rebuild valves (or just change the burst disk for a different working pressure.)

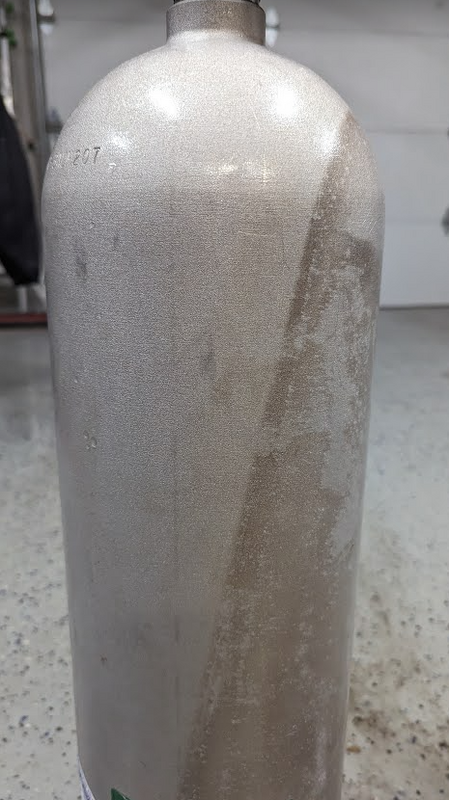

around here. With any abrasive you'll need to do the entire surface equally or it will look uneven. Ask me about the refrigerator I tried to clean once lol.

around here. With any abrasive you'll need to do the entire surface equally or it will look uneven. Ask me about the refrigerator I tried to clean once lol.