tmassey

Contributor

Hello!

I am the new owner of a used Poseidon compressor. It builds pressure (yay!) and the auto-drains operate (10 seconds every 12 or so minutes). However, the auto-drain manifold does not seem to operate the way that it's supposed to. So I'm trying to figure this out, which starts with figuring out what exactly this thing is.

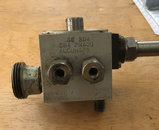

I've never seen an auto-drain system like this. I've attached some photos. The first is the auto-drain manifold on the compressor. The next is the only identification information I could find--and it seems that the second and third line are simply industry standard pressure and material labels. The last one is of the coalescer to the left of the drain manifold: I can't identify this one, either. If anyone could give me a name that would be great, and if anyone has any documentation I would be tremendously grateful.

The drain system seems quite complex. There are four knobs, one on each side. I spoke to Dana at Poseidon Air in VT. He stated these were valves to bypass the solenoid for manual drain. Unfortunately, at least some of them were stuck closed. So he suggested taking it apart and cleaning it. I've done so, and found a series of parts that could use some possible replacment, espeically o-rings. But with no idea of what this thing is, it's difficult to be certain of o-ring sizes and types, etc.

In addition, I'm getting stuff out of this thing that can only be described as chocolate-pudding-like. Yum. I think the coalescer is in serious need of attention -- at least heavy-duty cleaning. Dana said to loosen the knurled collar near the middle, but it's too tight: I can't get it off with a strap wrench and I'll have to find a pair of pliers big enough. I'm not eager to disconnect the myriad of tubes connected to this thing.

Like I said, the drains and coalescer seem quite complex. There is a drain after each stage (it's a 3-stage compressor), each of which go through the coalescer and into the drain manifold, and a fourth one coming from a coalescer in the bottom of the filter canister. There's all kinds of gas attachment points all over both the coalescer and the manifold, and the manifold has lots of valves, too! (The coalescers I'm used to seeing are one in, one out and one drain, and the drain manifolds I'm used to have external check valves and no manual valves.)

The picture of the coalescer is somewhat hard to see: the coalescer is painted black like everything on this Poseidon compressor... It's a relatively narrow tube, maybe 14" tall and 2" in diameter. The top half is cylindrical, with the final safety relief valve in the top. There is a square section mabye 1" tall in the middle, with the knurled collar screwed in immediately below this. The bottom half tapers like a cone to the final drain point in the bottom.

Again, thank you for any help you might be able to give me in identifying these two devices. I would appreciate any info you might have. Please ask any questions you have: I have *lots* more photos and notes...

I am the new owner of a used Poseidon compressor. It builds pressure (yay!) and the auto-drains operate (10 seconds every 12 or so minutes). However, the auto-drain manifold does not seem to operate the way that it's supposed to. So I'm trying to figure this out, which starts with figuring out what exactly this thing is.

I've never seen an auto-drain system like this. I've attached some photos. The first is the auto-drain manifold on the compressor. The next is the only identification information I could find--and it seems that the second and third line are simply industry standard pressure and material labels. The last one is of the coalescer to the left of the drain manifold: I can't identify this one, either. If anyone could give me a name that would be great, and if anyone has any documentation I would be tremendously grateful.

The drain system seems quite complex. There are four knobs, one on each side. I spoke to Dana at Poseidon Air in VT. He stated these were valves to bypass the solenoid for manual drain. Unfortunately, at least some of them were stuck closed. So he suggested taking it apart and cleaning it. I've done so, and found a series of parts that could use some possible replacment, espeically o-rings. But with no idea of what this thing is, it's difficult to be certain of o-ring sizes and types, etc.

In addition, I'm getting stuff out of this thing that can only be described as chocolate-pudding-like. Yum. I think the coalescer is in serious need of attention -- at least heavy-duty cleaning. Dana said to loosen the knurled collar near the middle, but it's too tight: I can't get it off with a strap wrench and I'll have to find a pair of pliers big enough. I'm not eager to disconnect the myriad of tubes connected to this thing.

Like I said, the drains and coalescer seem quite complex. There is a drain after each stage (it's a 3-stage compressor), each of which go through the coalescer and into the drain manifold, and a fourth one coming from a coalescer in the bottom of the filter canister. There's all kinds of gas attachment points all over both the coalescer and the manifold, and the manifold has lots of valves, too! (The coalescers I'm used to seeing are one in, one out and one drain, and the drain manifolds I'm used to have external check valves and no manual valves.)

The picture of the coalescer is somewhat hard to see: the coalescer is painted black like everything on this Poseidon compressor... It's a relatively narrow tube, maybe 14" tall and 2" in diameter. The top half is cylindrical, with the final safety relief valve in the top. There is a square section mabye 1" tall in the middle, with the knurled collar screwed in immediately below this. The bottom half tapers like a cone to the final drain point in the bottom.

Again, thank you for any help you might be able to give me in identifying these two devices. I would appreciate any info you might have. Please ask any questions you have: I have *lots* more photos and notes...