That pretty much summed up my feelings.@MarkFlory @cragfiend @cerich

Interested in your comments about wrapped tanks. Ignoring the DOT, CE discussion. I'm interested in hearing your experienced with them.

For me I'm super suspicious of the technology, and I say that coming from being a materials scientist in the aerospace world.

For me the issue is that you cannot see the interface between the liner and the carbon fiber wrap.. Carbon fiber and aluminum make a excellent battery and galvanic corrosion can move incredibly quickly. You can mitigate this with the right resin choice, even so if water gets between the layers all bets are off.

You could inspect them using ultrasonic inspection, but it would need a dedicated testing house, used to inspection carbon composites (its more complex than normal metallic components like cylinders and pipes) certainly well out of the scope of a fill station

Pressure testing "might" show up the defect, but when new the manufacturers pressurise the cylinder way beyond the elastic limit of the aluminum to pre load the carbon (putting it into tension) thus a normal hydro may pass the cylinder because the carbon is holding it together for the moment. but the corrosion is still there and advancing - and the liner is a very thin wall.

I'd be wary of a known cylinder with proved provenance form a reputable manufacturer and using it underwater (from a materials stand point) so interested in real world experiences with them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alleged illegal tanks sold by Add Helium-Heads up to any that may have purchased

- Thread starter cerich

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Status

- Not open for further replies.

By the numbers first the Add Helium product as sold.

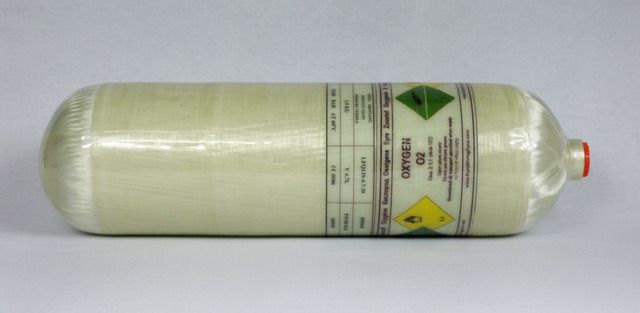

1. For reference the original Add Helium photo of the cylinder in question

2. Note the only certification identity is CE 0086

3. Look up CE 0086 its a notified body (not a manufacturing standard) and you get the BSI group UK England

https://www.bsigroup.com/Documents/product-certification/BSI-CE-marking-brochure-UK-EN.pdf

4. Where a Directive requires products or systems to be independently tested, certified or inspected you will need to use the services of a “Notified”, “Competent” or “Approved” Body. This is an organisation that has been notified to the European Commission by a Member State. BSI is a Notified Body (number 0086) for many of the European New Approach Directives.

5. For reference look up another CE 0086 certified product note that also has the CE0086 number is the same BSI notified body that did the compliance testing. Again it is not a manufacturing standard.

http://www.os-safetycenter.dk/pdf/ds/927500ds.pdf

6. Don’t confuse CE compliance testing to the CE manufacturing standard

Any more than DOT standard has to be specific to the numbers after the DOT

Also note DOT SP special permit numbers, the testing QA specification and independent verification

requirements,

Further the qualifications of the manufacturer to perform the task of design, manufacture inspection verification and test. In addition to the independent certification of materials used in manufacture.

7. Note the Add Helium product don’t give you the manufacturing standard or any of the above.

you have nothing. The suggestion is it because they have none.

8. Note Add Helium only give you a counterfeit notified body claim, BSI never tested this product for compliance to any standard

9. Note no standard of manufacture is given

1. For reference the original Add Helium photo of the cylinder in question

2. Note the only certification identity is CE 0086

3. Look up CE 0086 its a notified body (not a manufacturing standard) and you get the BSI group UK England

https://www.bsigroup.com/Documents/product-certification/BSI-CE-marking-brochure-UK-EN.pdf

4. Where a Directive requires products or systems to be independently tested, certified or inspected you will need to use the services of a “Notified”, “Competent” or “Approved” Body. This is an organisation that has been notified to the European Commission by a Member State. BSI is a Notified Body (number 0086) for many of the European New Approach Directives.

5. For reference look up another CE 0086 certified product note that also has the CE0086 number is the same BSI notified body that did the compliance testing. Again it is not a manufacturing standard.

http://www.os-safetycenter.dk/pdf/ds/927500ds.pdf

6. Don’t confuse CE compliance testing to the CE manufacturing standard

Any more than DOT standard has to be specific to the numbers after the DOT

Also note DOT SP special permit numbers, the testing QA specification and independent verification

requirements,

Further the qualifications of the manufacturer to perform the task of design, manufacture inspection verification and test. In addition to the independent certification of materials used in manufacture.

7. Note the Add Helium product don’t give you the manufacturing standard or any of the above.

you have nothing. The suggestion is it because they have none.

8. Note Add Helium only give you a counterfeit notified body claim, BSI never tested this product for compliance to any standard

9. Note no standard of manufacture is given

Last edited:

We know they are not DOT certified.

Could anyone here show us the law or regulations that prohibits someone in the USA from owning or filling this cylinder themselves or prohibiting a dive shop from filling it?

I can't find any such law and I would like to see it that would settle this discussion for good.

Could anyone here show us the law or regulations that prohibits someone in the USA from owning or filling this cylinder themselves or prohibiting a dive shop from filling it?

I can't find any such law and I would like to see it that would settle this discussion for good.

We know they are not DOT certified.

Could anyone here show us the law or regulations that prohibits someone in the USA from owning or filling this cylinder themselves or prohibiting a dive shop from filling it?

I can't find any such law and I would like to see it that would settle this discussion for good.

Mark

1. They are not CE certified either, but that’s not the kicker.

2. The kicker is they are counterfeit.

3. And they are counterfeit because of the counterfeit CE 0086 marking as explained earlier.

4. Regarding your separate question that of US laws tht prohibit someone in the USA owning or filling

these cylinders themselves or prohibiting a dive shop filling them: From your own DOT standards

(1) A cylinder filled with a non-liquefied compressed

gas (except gas in solution) must be offered for transportation in accordance with the requirements of this section and 173.301. In addition, a DOT specification cylinder must meet the requirements in 173.301a, 173.302a and 173.305, as applicable. UN pressure receptacles must meet the requirements in 173.301b and 173.302b, as applicable. Where more than one section applies to a cylinder, the most restrictive requirements must be followed.

(2) Adsorbed gas. A cylinder filled with an adsorbed gas must be offered for transportation in accordance with the requirements of paragraph (d) of this section, 173.301, and 173.302c. UN cylinders must meet the requirements in 173.301b and 173.302b, as applicable. Where more than one section applies to a cylinder, the most restrictive requirements must be followed.

(b) Aluminum cylinders in oxygen service. Eachaluminum cylinder filled with oxygen must meet all of the following conditions:

(1) Metallic portions of a valve that may come into contact with the oxygen in the cylinder must be constructed of brass or stainless steel.

(2) Except for UN cylinders, each cylinder opening must be configured with straight threads only.

(3) Each UN pressure receptacle must be cleaned in accordance with the requirements of ISO 11621 (IBR, see171.7 or this subchapter). Each DOT cylinder must be cleaned in accordance with the requirements of GSA Federal Specification RR-C-901D, paragraphs 3.3.1 and 3.3.2 (IBR, see 171.7 of this subchapter). Cleaning agents equivalent to those specified in Federal Specification RR-C-901D may be used provided they do not react with oxygen. One cylinder selected at random from a group of 200 or fewer and cleaned at the same time must be tested for oil contamination in accordance with Federal Specification RR-C- 901D, paragraph 4.3.2, and meet the specified standard of cleanliness.

(4) The pressure in each cylinder may not exceed 3000 psig at 21 °C (70 °F).

(e) DOT 3AL cylinders manufactured of 6351-T6 aluminum alloy. Suitable safeguards should be provided to protect personnel and facilities should failure occur while filling cylinders manufactured of aluminum alloy 6351-T6 used in self-contained underwater breathing apparatus (SCUBA), self- contained breathing apparatus (SCBA) or oxygen service. The cylinder filler should allow only those individuals essential to the filling process to be in the vicinity of the cylinder during the filling process.

(2) Cylinders must be equipped with a pressure relief device in accordance with 173.301(f) and, for DOT 39 cylinders offered for transportation after October 1, 2008, for the other DOT specification cylinders with the first requalification due after October 1, 2008, or for the UN pressure receptaclesprior to initial use:

(i) The rated burst pressure of a rupture disc for DOT 3A, 3AA,

3AL, 3E, and 39 cylinders, and UN pressure receptacles ISO 9809- 1, ISO 9809-2, ISO 9809-3 and ISO 7866 cylinders must be 100% of the cylinder minimum test pressure with a tolerance of plus zero to minus 10%; and

(ii) The rated burst pressure of a rupture disc for a DOT

3HT cylinder must be 90% of the cylinderminimum test pressure with a tolerance of plus zero to minus 10%.

(ii) Is capable of passing, as demonstrated by design testing, the Flame Penetration Resistance Test in appendix E to part 178 of this subchapter;

Ah. So the water is the reason they are not commonly used for scuba tanks, and yet are used commonly in non-underwater applications?For me the issue is that you cannot see the interface between the liner and the carbon fiber wrap.. Carbon fiber and aluminum make a excellent battery and galvanic corrosion can move incredibly quickly. You can mitigate this with the right resin choice, even so if water gets between the layers all bets are off.

Being a volunteer firefighter at two different departments for about a year at each, carbon fiber wrapped tanks seem almost universal for the firefighter's SCBA units. At the time, I had no experience with scuba and I guess just assumed the CF wrapped tanks were so they were lighter, which I still think is why. Going into a fire with an SCBA, full bunker gear, axes/sledges/chainsaws/firehose and rescuing people, you want your tank to be lightweight. An AL80 wouldn't be fun at all. My first department had 3000 PSI carbon fiber tanks, the second department had smaller 4500 PSI tanks (probably the "30 minute tanks" as they are called, holding 45 cu ft of air at 4500 PSI). My first department later switched out to the smaller 4500 PSI tanks, again size and weight are concerns. Unlike going underwater, a tank doesn't become (almost) weightless, you have to carry it the entire time while simultaneously working your ass off, so lightweight is a priority.

So is the short answer to my question yes they are legal to own and fill in the in the US?

The the restrictions come in at "offered for transportation"

The rest are guidelines, using the word "should" and not the word "required"

I did talk to the DOT before I bought my own personal compressor to find out what was required of me to fill my own tanks and was surprised that there was absolutely nothing I needed to do legally.

I was told the regulations on all of these tanks including welding tanks is all concerning transportation not ownership or use . OSHA required my Helium and O2 bottles to be chained up or secured, But that was really for commercial use only. I know civil liability is a whole different story if someone gets hurt ,But at the end of the day these tanks are perfectly legal to own and fill in the USA for private use.

The the restrictions come in at "offered for transportation"

The rest are guidelines, using the word "should" and not the word "required"

I did talk to the DOT before I bought my own personal compressor to find out what was required of me to fill my own tanks and was surprised that there was absolutely nothing I needed to do legally.

I was told the regulations on all of these tanks including welding tanks is all concerning transportation not ownership or use . OSHA required my Helium and O2 bottles to be chained up or secured, But that was really for commercial use only. I know civil liability is a whole different story if someone gets hurt ,But at the end of the day these tanks are perfectly legal to own and fill in the USA for private use.

St John the Diver

Contributor

hope you are not referring to me .......my sfa chapter guys at 1-18 (life member ) might take offense at that (by the way my name is the same on THEIR blog as well,,, oh but I forgot you cant see it if your not a member

Nobody cares.

Last edited:

Rick Sanders

Registered

He will never agree to that... That's called manning up! I hope my tax dollars are not paying for him; as much as he is on this forum, not much work getting done.. But I really don't think Shawn Robotka works for DOD.Would you please post the PM's between you, me and St John? You have my permission.

St. John, you ready to have people see me apologize to you, then you turn around and make a personal attack? C'mon, you are anonymous! It won't hurt you professional reputation or your DoD employment at all. Pretty please with sugar on top?

Seriously, they make the MOD pulling Mark Stephens post absolutely hilarious! Be a pal!

It is the PM string that I started, entitled "My Error", if that helps.

So is the short answer to my question yes they are legal to own and fill in the in the US?

The the restrictions come in at "offered for transportation"

The rest are guidelines, using the word "should" and not the word "required"

I did talk to the DOT before I bought my own personal compressor to find out what was required of me to fill my own tanks and was surprised that there was absolutely nothing I needed to do legally.

I was told the regulations on all of these tanks including welding tanks is all concerning transportation not ownership or use . OSHA required my Helium and O2 bottles to be chained up or secured, But that was really for commercial use only. I know civil liability is a whole different story if someone gets hurt ,But at the end of the day these tanks are perfectly legal to own and fill in the USA for private use.

Mark

With respect all this about DOT stuff and the like is a sideline issue. These tanks are supect counterfeit.

But if you would prefer Im happy to discuss the supplier of these tanks to Add Helium

and we can trace it back to the source in China if you like. (eventually I guess)

Just lets get to a point where your need for risk doesnt involve my need to feed my family at my work.

If you check out the origin and supplier of these Add Helium cylinders you will find the

Euro Diving Zone

SCUBA Carbon Fiber Bare Cylinder

They specify only the following (note I have included the same miss spelling)

………………………………………………………………………………………………….

Anodized Carbon Fiber fully wrapped Aluminum Alloy Cylinder.

Specifications:

* Anodized Carbon Fiber fully wrapped Aluminum Alloy Cylinder.

* Work Pressure: 300 Bar (4350 PSI)

* Burst Pressure: 450 Bar (6525 PSI)

* Neck Threads: M18*1.5

* Vavle is not included. 100% Oxygen Compatible.

Size Available:

2L Outer Diameter * Length, 101*438mm

………………………………………………………………………………..

1. First note this “Carbon “Fiber” looks kind of white to me not the normal black you would expect

from carbon fibres,

So first I would suspect that its not a carbon fibre material.

2. Note next the label attached.

First part of it is written upside down, it is poorly printed with some of the printing under printed and the outer surround fades out at the lower edge.

Almost as if a “stick on patch has been laminated onto the outer shell gel cost rather than the label being attached in manufacturing to the final fibre winding and the clear gel coat applied after.

A physical examination would show if the label is deep in the gel coat or if it has been “attached” over the gel coat and additional gel coat applied at a later stage.

3. There is NO standard of manufacture.

The label “OXYGEN O2 Class 2.5.1 UN Nr 1072 is an erroneous contents label.

Photo below taken from the Euro Diving Zone website for reference purpose only

Now if you could post photos of your cylinders, that would be great especially the base underside,

the neck trasition to valve, and a close up of the lable attachment all around. Thanks Iain

Last edited:

St John the Diver

Contributor

So is the short answer to my question yes they are legal to own and fill in the in the US?

The the restrictions come in at "offered for transportation"

The rest are guidelines, using the word "should" and not the word "required"

I did talk to the DOT before I bought my own personal compressor to find out what was required of me to fill my own tanks and was surprised that there was absolutely nothing I needed to do legally.

I was told the regulations on all of these tanks including welding tanks is all concerning transportation not ownership or use . OSHA required my Helium and O2 bottles to be chained up or secured, But that was really for commercial use only. I know civil liability is a whole different story if someone gets hurt ,But at the end of the day these tanks are perfectly legal to own and fill in the USA for private use.

All of that's exactly true. There's no requirement to hydrotest scuba bottles. It's just industry standard. And there are perfectly safe non-DOT cylinders. We fill British stamped Faber bottles without thinking twice. It's because we trust Faber. The odd Mark-15 sphere gets filled too. As do euro-spec 3 litre rebreather bottles. But I would never in a million years fill aluminum/composite cylinders no matter where they were made that have been used in salt water. Not Draeger, not US made SCBA cylinders, and most certainly not Chinese made bottles with fake CE on them. And why in the world would anyone use them? For every ounce of weight you remove from them you need to add an ounce of lead someplace. Unless you want to drag them into the Thai jungle for diving in some hole in the ground and can stuff your weight pockets full of stones when you get there you're not saving any weight.

I think the demonstrated problem here is lack of integrity regarding selling these using fake "certification" weasel-words. And the sideshow of what the principal in AH has done with his life isn't exactly something that suggests confidence in ethical practices and thus direct inspire confidence in these cylinders.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 73

- Views

- 16,160